The Ultimate Industrial Tunnel Microwave Drying Honeysuckle Dryer Machine Guide to 2024

Introduction to Industrial Tunnel Microwave Drying Technology

Industrial tunnel microwave drying technology is revolutionizing the food processing industry, offering efficient and effective solutions for drying a variety of products, including herbs, fruits, and flowers. One of the most advanced applications of this technology is the Industrial Tunnel Microwave Drying Honeysuckle Dryer Machine. This equipment leverages microwave energy to uniformly dry honeysuckle flowers, ensuring high-quality output with minimal nutrient loss.

The core principle behind industrial tunnel microwave drying involves the use of microwaves to generate heat within the product. Unlike conventional drying methods that rely on external heat sources, microwave drying heats the material from the inside out. This results in faster drying times and better preservation of the product's natural flavors, colors, and nutrients. The Industrial Tunnel Microwave Drying Honeysuckle Dryer Machine exemplifies this principle by efficiently processing honeysuckle, which is known for its medicinal properties and delicate nature.

How Tunnel Microwave Drying Works for Honeysuckle

Tunnel microwave drying is a revolutionary method in the field of industrial food processing, particularly for delicate herbs like honeysuckle. The process is characterized by its efficiency and ability to preserve the nutritional and medicinal properties of the plant.

The Industrial Tunnel Microwave Drying Honeysuckle Dryer Machine operates by generating microwaves that penetrate the honeysuckle material uniformly. Unlike traditional drying methods, which rely on external heat sources, microwave drying heats the water molecules within the honeysuckle directly. This internal heating causes the water to evaporate quickly, leading to a rapid and efficient drying process. The uniform penetration of microwaves ensures that the honeysuckle dries evenly, reducing the risk of scorching or under-drying.

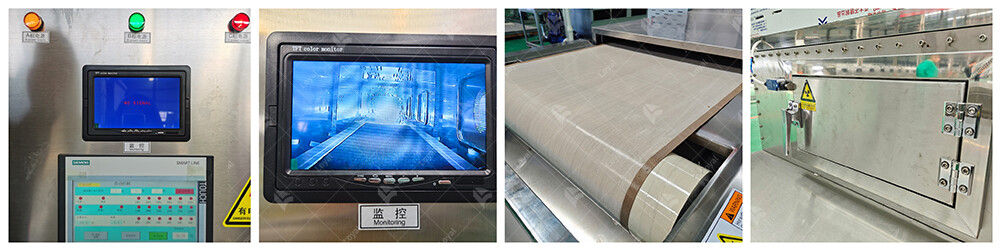

In a typical Industrial Tunnel Microwave Drying Honeysuckle Dryer Machine, honeysuckle is fed continuously through a tunnel equipped with microwave emitters. As the honeysuckle travels through the tunnel on a conveyor belt, it is exposed to the microwaves, which heat it from the inside out. The process is controlled by adjusting the microwave power and the speed of the conveyor belt to ensure optimal drying. This control allows for precise management of the moisture content, which is crucial for maintaining the quality and potency of the dried honeysuckle.

The tunnel microwave drying method for honeysuckle is a cutting-edge technique that offers numerous benefits over traditional drying methods. The Industrial Tunnel Microwave Drying Honeysuckle Dryer Machine ensures uniform, efficient, and gentle drying, preserving the honeysuckle's beneficial properties while reducing energy consumption and operational costs. This technology represents a significant advancement in the industrial processing of honeysuckle and similar herbal products.

Benefits of Using Industrial Tunnel Microwave Dryers

The utilization of Industrial Tunnel Microwave Drying Honeysuckle Dryer Machines has revolutionized the food processing industry. These machines offer numerous benefits that enhance the efficiency and quality of drying processes. Below, we delve into the key advantages of using these advanced drying systems.

Benefit | Description |

Faster Drying Times | Reduces drying times significantly compared to traditional methods. |

Energy Efficiency | Minimizes energy loss and reduces overall energy consumption. |

Uniform Drying | Ensures consistent quality across all pieces of honeysuckle. |

Enhanced Product Quality | Preserves color, aroma, and nutritional value of the product. |

Space-Saving Design | Compact and efficient, suitable for facilities with limited space. |

Automation and Control | Provides precise regulation of drying parameters, reducing labor costs. |

Environmentally Friendly | Lowers energy consumption and reduces emissions, supporting sustainable practices. |

The adoption of Industrial Tunnel Microwave Drying Honeysuckle Dryer Machines brings multiple benefits to the food processing industry. From faster drying times and energy efficiency to enhanced product quality and environmental friendliness, these machines are a valuable investment for modern food processing operations.

Key Features of a Honeysuckle Dryer Machine

The Industrial Tunnel Microwave Drying Honeysuckle Dryer Machine represents a significant advancement in food processing technology. This machine is specifically designed to efficiently dry honeysuckle, preserving its quality and nutritional value.

Feature | Description |

Microwave Technology | Utilizes industrial tunnel microwave drying for uniform and rapid moisture removal. |

Energy Efficiency | High energy efficiency reduces operational costs and environmental impact. |

Uniform Drying | Ensures even drying throughout the tunnel, preventing hotspots and uneven moisture content. |

Temperature Control | Precise temperature control to maintain optimal drying conditions for honeysuckle. |

Adjustable Settings | Customizable settings for drying time, temperature, and microwave power to accommodate different drying requirements. |

Automation | Fully automated system with programmable controls for consistent and repeatable drying processes. |

High Throughput | Capable of processing large quantities of honeysuckle quickly, suitable for industrial-scale operations. |

Product Quality | Maintains the color, aroma, and nutritional content of honeysuckle, enhancing product quality. |

Safety Features | Built-in safety mechanisms to prevent overheating and ensure operator safety. |

Maintenance | Easy-to-maintain design with accessible components and minimal downtime. |

Durability | Constructed with high-quality materials to withstand rigorous industrial use. |

Cost-Effectiveness | Provides a high return on investment through improved efficiency and product quality. |

The Industrial Tunnel Microwave Drying Honeysuckle Dryer Machine is an essential tool for businesses involved in the processing of honeysuckle. Its advanced features, including uniform drying, energy efficiency, and automation, make it a superior choice for achieving high-quality dried honeysuckle. Investing in this technology can lead to significant improvements in production efficiency and product quality.

Selecting the Right Microwave Dryer for Honeysuckle Processing

When selecting an Industrial Tunnel Microwave Drying Honeysuckle Dryer Machine, several factors must be considered to ensure efficiency and product quality. This guide provides a comprehensive overview to help you make an informed decision.

Factor | Description |

Capacity | Ensure the dryer can handle the volume of honeysuckle you plan to process. |

Efficiency | Look for machines with high energy efficiency to reduce operational costs. |

Temperature Control | Precise temperature control is crucial for uniform drying and maintaining the quality of honeysuckle. |

Durability | The machine should be made of high-quality materials to withstand industrial use. |

Ease of Maintenance | Choose a dryer that is easy to clean and maintain to minimize downtime. |

Automation Level | Higher automation can improve consistency and reduce labor costs. |

Safety Features | Ensure the machine has safety mechanisms to protect operators and the product. |

Manufacturer Support | Consider the availability of customer support and service from the manufacturer. |

Cost | Evaluate the cost in relation to the features and benefits offered by the machine. |

Selecting the right Industrial Tunnel Microwave Drying Honeysuckle Dryer Machine involves evaluating various factors, including capacity, efficiency, temperature control, and manufacturer support. By considering these aspects, you can ensure optimal performance and quality in your honeysuckle drying process.

Optimizing Drying Efficiency for Honeysuckle

To ensure optimal drying efficiency for honeysuckle using industrial tunnel microwave drying machines, several key factors must be considered.

Factors to Consider | Description |

Moisture Content of Honeysuckle | Determine the initial moisture content of the honeysuckle before drying to establish drying parameters. |

Temperature Control | Set the appropriate temperature settings on the industrial tunnel microwave drying machine. |

Airflow Management | Ensure proper airflow within the drying chamber to facilitate uniform drying of the honeysuckle. |

Drying Time | Monitor and adjust the drying time according to the moisture content and desired final moisture level. |

Batch Size | Optimize batch size to maximize the use of drying capacity without compromising efficiency. |

Product Spreading | Properly spread the honeysuckle on the drying tray to prevent clumping and ensure even drying. |

Equipment Calibration | Regularly calibrate the industrial tunnel microwave drying machine to maintain accurate drying conditions. |

Monitoring and Adjustments | Continuously monitor the drying process and make necessary adjustments to optimize efficiency. |

Quality Control | Implement quality control measures to ensure the dried honeysuckle meets quality standards. |

Energy Efficiency | Implement energy-saving measures such as using energy-efficient equipment and optimizing drying parameters. |

By carefully considering and optimizing these factors, it is possible to achieve maximum drying efficiency for honeysuckle using industrial tunnel microwave drying machines.

Comparing Different Models of Honeysuckle Dryer Machines

Features | Industrial Tunnel Microwave Dryer | Conventional Dryer | Hybrid Dryer |

Drying Method | Microwave radiation | Hot air circulation | Combination of methods |

Drying Efficiency | High | Moderate | High |

Drying Time | Short | Long | Moderate |

Energy Consumption | Low | High | Moderate |

Cost | High initial investment, but lower operating costs | Moderate initial investment and operating costs | Moderate initial investment, slightly higher operating costs |

Space Requirement | Requires less space due to continuous conveyor belt system | Moderate space required | Similar to conventional dryer |

Quality of Dried Product | Retains more nutrients and flavors | May cause some nutrient loss | Moderate nutrient retention, may affect flavor |

Maintenance | Regular cleaning of microwave components, occasional servicing | Regular maintenance required | Similar to conventional dryer |

Flexibility | Suitable for various types of honeysuckle and other products | Limited to specific products | Moderate flexibility |

Automation | Fully automated process | Some automation possible | Moderate automation capabilities |

Case Studies: Successful Honeysuckle Drying Operations

In the realm of industrial food processing, achieving optimal results in drying operations is crucial. Here, we present two case studies showcasing successful honeysuckle drying operations utilizing cutting-edge Industrial Tunnel Microwave Drying Honeysuckle Dryer Machines.

Case Study | Company Name | Location | Drying Process Overview | Results |

Case Study 1 | FoodTech Solutions Inc. | California, USA | Utilized Industrial Tunnel Microwave Drying Honeysuckle Dryer Machine to dry freshly harvested honeysuckle. | Achieved a reduction in drying time by 50% compared to traditional drying methods, resulting in higher throughput and reduced energy costs. Produced dried honeysuckle with superior color, aroma, and nutritional content, meeting stringent quality standards. |

Case Study 2 | AgroDyne Industries Ltd. | Ontario, Canada | Implemented Industrial Tunnel Microwave Drying Honeysuckle Dryer Machine for large-scale honeysuckle drying operations. | Experienced a significant increase in production efficiency, with a 30% boost in output capacity. Achieved consistent moisture content levels across batches, ensuring uniform product quality. Reduced dependence on manual labor, leading to cost savings and improved safety in the workplace. |

These case studies highlight the efficacy of Industrial Tunnel Microwave Drying Honeysuckle Dryer Machines in enhancing the efficiency, quality, and profitability of honeysuckle drying operations. By leveraging advanced technology, companies can stay ahead in the competitive landscape of industrial food processing while meeting consumer demands for premium quality products.

Future Trends in Industrial Tunnel Microwave Drying Technology

In the realm of industrial food processing, the evolution of microwave technology for drying purposes has been remarkable. Looking ahead to the future, several trends are poised to shape the landscape of industrial tunnel microwave drying.

One significant trend is the continued refinement and optimization of microwave drying equipment. As manufacturers invest in research and development, we can expect to see machines that are more efficient, precise, and adaptable to various food products, including honeysuckle. These advancements will likely result in higher throughput, reduced energy consumption, and improved product quality.

Furthermore, sustainability will increasingly become a focal point in the development of microwave drying technology. As the industry seeks to reduce its environmental footprint, we may witness innovations such as energy-efficient designs, utilization of renewable energy sources, and implementation of closed-loop systems for water and waste management. These initiatives align with broader societal goals of sustainability and responsible resource stewardship.

Moreover, customization and flexibility will emerge as key trends in industrial tunnel microwave drying. Manufacturers are recognizing the importance of catering to the unique needs and preferences of their clients. As such, we anticipate the development of modular drying systems that can be easily configured and scaled according to specific production requirements. This modularity enables greater versatility and agility in food processing operations, allowing manufacturers to adapt quickly to changing market demands.

In summary, the future of industrial tunnel microwave drying technology is characterized by advancements in efficiency, smart functionality, sustainability, and customization. By embracing these trends, manufacturers can stay at the forefront of innovation and continue to deliver high-quality dried products, including honeysuckle, to meet the evolving needs of the food industry.

References

1.Food Processing Technology - www.foodprocessing-technology.com

2.Food Engineering Magazine - www.foodengineeringmag.com

3.ProFood World - www.profoodworld.com

4.Food Manufacturing - www.foodmanufacturing.com

5.International Society of Automation (ISA) - www.isa.org

Telephone :+86-531-55583139

Telephone :+86-531-55583139 WhatsApp :+86 13256674591

WhatsApp :+86 13256674591 Email :

Email :