The Ultimate Microwave Chalk Pastel Sterilizing Dryer Drying Machine Guide to 2024

Introduction to Microwave Drying Sterilizers

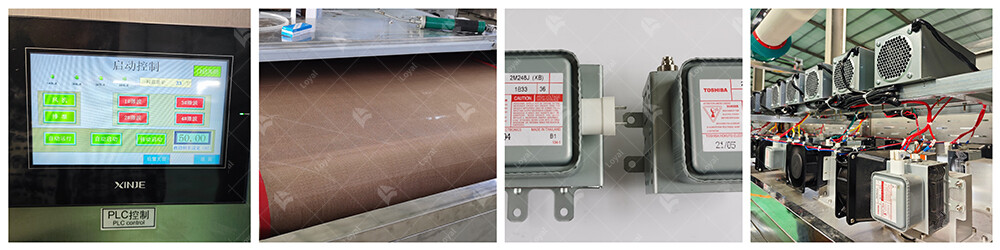

Microwave drying sterilizers represent a significant advancement in industrial food machinery, combining the processes of drying and sterilizing in one efficient system. The Microwave Chalk Pastel Sterilizing Dryer Drying Machine, a cutting-edge example of this technology, uses microwave energy to heat and sterilize food products rapidly. This method ensures the elimination of harmful microorganisms while preserving the nutritional and sensory qualities of the food.

The principle behind microwave drying sterilizers is straightforward yet highly effective. Microwaves generate heat by causing water molecules within the food to vibrate, producing internal friction that heats and dries the product. This internal heating mechanism makes microwave drying sterilizers faster and more energy-efficient than conventional methods. Additionally, the microwave drying process can be precisely controlled, making it suitable for a wide range of food products and applications.

Microwave Drying Process Explained

The microwave drying process involves several critical steps that ensure the effective drying and sterilization of food products. First, the food product is placed in the Microwave Chalk Pastel Sterilizing Dryer Drying Machine. Once inside, microwaves penetrate the food, causing the water molecules to vibrate and generate heat. This heat rapidly evaporates the moisture, effectively drying the product from the inside out. The controlled environment within the machine ensures even drying and prevents overcooking or undercooking of the food.

Traditional drying methods, such as air drying or freeze-drying, can take several hours or even days to complete. In contrast, the microwave drying process can often be completed in a matter of minutes. This efficiency not only saves time but also reduces energy consumption, making it a more sustainable option for food processing companies. The Microwave Chalk Pastel Sterilizing Dryer Drying Machine exemplifies this efficiency, providing a quick and effective solution for drying and sterilizing food products.

Another critical aspect of the microwave drying process is its ability to maintain the quality of the food product. Traditional drying methods can often result in the loss of essential nutrients and changes in texture and flavor. However, the rapid and controlled drying process of the microwave sterilizer helps to preserve these qualities. The Microwave Chalk Pastel Sterilizing Dryer Drying Machine ensures that food products retain their original taste, texture, and nutritional value, making it an ideal choice for high-quality food processing.

Overall, the microwave drying process is a revolutionary method that combines speed, efficiency, and quality. The Microwave Chalk Pastel Sterilizing Dryer Drying Machine stands at the forefront of this technology, offering food processing companies an advanced solution for their drying and sterilizing needs. By understanding and utilizing this process, companies can enhance their production capabilities and deliver superior products to the market.

Types of Microwave Drying Sterilizers

Microwave drying sterilizers are versatile machines designed to meet various industrial needs. The following table outlines the main types:

Type | Description | Applications |

| Batch Microwave Sterilizers | Operate in batches, suitable for small-scale production. | Small food processing units, pharmaceuticals. |

| Continuous Microwave Sterilizers | Offer continuous processing for large-scale production. | Large food manufacturing plants, high-volume pharmaceutical production. |

| Hybrid Microwave Sterilizers | Combine microwave with other sterilization methods (e.g., UV or steam) for enhanced efficacy. | Sensitive food products, requiring extra sterilization. |

| Compact Microwave Sterilizers | Smaller, portable units ideal for limited space or mobile operations. | Research labs, small food production setups, pilot plants. |

| Custom Microwave Sterilizers | Tailored to specific industrial needs, including size, power, and application-specific features. | Specialized food processing industries, bespoke pharmaceutical manufacturing. |

Microwave Sterilization vs. Traditional Methods

The following table highlights the differences between microwave sterilization and traditional sterilization methods:

Feature | Microwave Sterilization | Traditional Methods |

| Speed | Fast, significantly reduces processing time. | Slower, often requiring extended periods for effective sterilization. |

| Energy Efficiency | High, uses less energy due to shorter processing times. | Lower, typically consumes more energy. |

| Uniformity | Ensures even heating and sterilization throughout the product. | May result in uneven heating, leading to potential hotspots. |

| Preservation of Nutrients | Better retention of nutrients and flavors due to shorter exposure. | Potential loss of nutrients and flavors due to prolonged exposure to heat. |

| Operational Cost | Lower long-term costs due to energy savings and efficiency. | Higher due to longer processing times and greater energy consumption. |

| Environmental Impact | Reduced carbon footprint, more eco-friendly. | Higher environmental impact due to increased energy usage. |

Applications of Microwave Sterilizers in Food Industry

Microwave sterilizers, such as the Microwave Chalk Pastel Sterilizing Dryer Drying Machine, have become increasingly significant in the food industry. These machines offer a highly efficient method for sterilizing various food products, ensuring safety and extending shelf life. The microwave drying process eliminates harmful microorganisms by utilizing dielectric heating, which penetrates the food uniformly and rapidly.

One of the primary applications is in the sterilization of packaged foods. The Microwave Chalk Pastel Sterilizing Dryer Drying Machine can process a variety of food items, including ready-to-eat meals, dairy products, and beverages. This versatility is crucial for maintaining the quality and safety of foods without compromising nutritional value or taste.

Another critical application is in the drying and sterilization of spices and herbs. Traditional methods can often degrade the flavor and potency of these ingredients. However, the Microwave Chalk Pastel Sterilizing Dryer Drying Machine preserves the essential oils and flavors while ensuring the products are free from pathogens.

The machine is also used in the processing of fruits and vegetables. By rapidly drying and sterilizing these products, the Microwave Chalk Pastel Sterilizing Dryer Drying Machine helps in maintaining their nutritional content and natural color, which is often lost in conventional drying methods.

Efficiency of Microwave Drying Sterilizers

The efficiency of microwave drying sterilizers, particularly the Microwave Chalk Pastel Sterilizing Dryer Drying Machine, is one of their most significant advantages. These machines operate by converting microwave energy into heat within the product itself. This process is much faster compared to conventional heating methods, leading to significant time and energy savings.

One key aspect of their efficiency is the uniformity of heating. Traditional drying methods often result in uneven heating, leading to over-processed or under-processed areas within the product. The Microwave Chalk Pastel Sterilizing Dryer Drying Machine ensures that the entire product is heated evenly, which is essential for consistent quality and safety.

Moreover, these machines are designed to optimize energy use. The direct conversion of microwave energy into heat minimizes energy loss, making the process more cost-effective. This energy efficiency is particularly important in large-scale food processing operations where energy costs can significantly impact the overall profitability.

Additionally, the Microwave Chalk Pastel Sterilizing Dryer Drying Machine offers precise control over the drying and sterilization parameters. This level of control allows operators to adjust the process according to the specific requirements of different food products, ensuring optimal results every time.

In summary, the Microwave Chalk Pastel Sterilizing Dryer Drying Machine represents a significant advancement in food sterilization and drying technology. Its applications in the food industry are diverse, ranging from packaged foods to spices and fresh produce. Its efficiency in terms of time, energy, and uniformity of processing makes it an invaluable asset for modern food production facilities. As the industry continues to evolve, the role of microwave sterilizers like the Microwave Chalk Pastel Sterilizing Dryer Drying Machine will undoubtedly become even more critical in ensuring food safety and quality.

Technical Parameters

Technical Parameters Of Continuous Microwave Dryer Industrial Microwave Drying Machine | |||||

| Model | Size LWH(Can be customized according to the customer's requirements) | Output power | Dewaterability | Sterilization capacity | Baking and Roasting capacity (Depends on different raw material) |

| LY-10KW | 5000mm825mm1750mm | ≥10KW | 10KG/Hour | 100KG/Hour | 30-50KG/Hour |

| LY-20KW | 8000mm825mm1750mm | ≥20KW | 20KG/Hour | 200KG/Hour | 60-100KG/Hour |

| LY-30KW | 8500mm1160mm1750mm | ≥30KW | 30KG/Hour | 300KG/Hour | 90-150 KG/Hour |

| LY-40KW | 10000mm1160mm1750mm | ≥40KW | 40KG/Hour | 40KG/Hour | 120-200KG/Hour |

| LY-50KW | 12500mm1160mm1750mm | ≥50KW | 50KG/Hour | 500KG/Hour | 150-250KG/Hour |

| LY-60KW | 13500mm1450mm1750mm | ≥60KW | 60KG/Hour | 600KG/Hour | 180-300KG/Hour |

| LY-70KW | 13500mm1500mm1750mm | ≥70KW | 70KG/Hour | 700KG/Hour | 210-350KG/Hour |

| LY-80KW | 13500mm1650mm1750mm | ≥80KW | 80KG/Hour | 800KG/Hour | 240-400KG/Hour |

| LY-100KW | 16800mm1650mm1750mm | ≥100KW | 100KG/Hour | 1000KG/Hour | 300-500KG/Hour |

| LY-150KW | 22400mm1850mm1750mm | ≥150KW | 150KG/Hour | 1500KG/Hour | 450-750KG/Hour |

| LY-200KW | 27000mm1850mm1750mm | ≥250KW | 250KG/Hour | 2500KG/Hour | 750-1250/Hour |

| LY-300KW | 32000mm1850mm1750mm | ≥300KW | 300KG/Hour | 3000KG/Hour | 900-1500KG/Hour |

Power Supply | 380V±10% 50Hz±1% Three-Phase Five-Wire | ||||

Microwave Output Frequency | 2450±50Mhz | ||||

Microwave Input Apparent Power | ≤168Kva | ||||

Microwave Output Power | ≥120Kw | ||||

Microwave Power Adjustment Range | 0-30Kw(Adjustable) | ||||

Ambient Temperature | -5-40°C | ||||

Relative Humidity | ≤80%, Surrounding Environment:No Corrosive Gas, Conductive Dust And Explosive Gas | ||||

Transmission Speed | 0-10m/Min(Adjustable) | ||||

Environmental Impact of Microwave Sterilizers

Microwave sterilizers offer a more eco-friendly alternative to traditional methods due to their energy efficiency and reduced chemical usage. By utilizing electromagnetic waves for sterilization, these machines minimize the need for harmful chemicals, thereby reducing pollution and environmental damage.

Furthermore, microwave sterilizers operate at lower temperatures compared to conventional methods, leading to less energy consumption and lower greenhouse gas emissions. Their closed-loop systems also prevent the release of contaminants into the atmosphere, ensuring minimal impact on air quality.

In addition, the compact design of microwave sterilizers results in smaller footprints and reduced resource consumption during manufacturing and transportation. Overall, the environmental benefits of microwave sterilizers make them a sustainable choice for food processing facilities worldwide.

Regulatory Standards for Microwave Sterilizers

As microwave sterilizers gain popularity in the food industry, regulatory bodies have established stringent standards to ensure product safety and quality. These standards cover various aspects, including equipment design, operation procedures, and hygiene practices.

For instance, the Food and Drug Administration (FDA) in the United States requires microwave sterilizers to meet specific performance criteria to effectively eliminate harmful pathogens while preserving food quality. Similarly, the European Union has implemented regulations under the CE marking system to certify the compliance of microwave sterilizers with health and safety requirements.

Moreover, industry organizations such as the International Organization for Standardization (ISO) and the American National Standards Institute (ANSI) have developed guidelines for the testing and validation of microwave sterilization processes. Adhering to these standards is essential for manufacturers to ensure the reliability and effectiveness of their products.

Importance of Operator Training

Training for operators of the Microwave Chalk Pastel Sterilizing Dryer Drying Machine begins with a comprehensive understanding of the machine's functions and capabilities. Operators must be familiar with:

1. Machine Setup and Calibration: Proper setup and calibration are essential for the efficient operation of the Microwave Chalk Pastel Sterilizing Dryer Drying Machine. Training includes step-by-step instructions on configuring the machine for different drying and sterilizing requirements.

2. Safety Protocols: Safety is paramount when operating industrial food machinery. Operators are trained on the safety features of the machine, including emergency shut-off procedures, safe handling of materials, and protective measures to prevent accidents.

3. Operating Procedures: Detailed training on operating procedures ensures that operators can run the Microwave Chalk Pastel Sterilizing Dryer Drying Machine effectively. This includes loading and unloading materials, adjusting settings for different types of chalk pastels, and monitoring the drying and sterilizing process.

Ongoing Support and Resources

In addition to initial training, ongoing support is vital to address any issues that may arise during the operation of the Microwave Chalk Pastel Sterilizing Dryer Drying Machine. Support services typically include:

1. Technical Support: Access to technical support is crucial for troubleshooting any operational issues. This includes phone and email support from technicians who can provide immediate assistance and guidance.

2. Maintenance and Repair Services: Regular maintenance is essential for the longevity and performance of the Microwave Chalk Pastel Sterilizing Dryer Drying Machine. Support packages often include scheduled maintenance services and access to repair technicians.

3. Training Updates: As technology evolves, updates to training programs ensure that operators stay informed about the latest advancements and best practices for using the Microwave Chalk Pastel Sterilizing Dryer Drying Machine. This may include refresher courses and new training modules.

4. Documentation and Manuals: Comprehensive documentation, including user manuals and troubleshooting guides, provides operators with a valuable resource for independent problem-solving and reference.

Future Trends in Microwave Sterilizer Technology

Looking ahead to the future, several trends are shaping the evolution of microwave sterilizer technology. One key trend is the integration of advanced sensors and automation systems to enhance process control and efficiency. By monitoring key parameters such as temperature, pressure, and moisture levels in real-time, these systems optimize sterilization cycles and minimize energy consumption.

Another trend is the development of multi-functional microwave sterilizers capable of handling a wide range of food products and packaging materials. This versatility allows food manufacturers to streamline their operations and adapt to changing market demands more effectively.

Furthermore, ongoing research in areas such as microwave-assisted thermal pasteurization and pulsed electric field technology is paving the way for even more efficient and sustainable sterilization methods. These innovations hold the promise of further reducing processing times and energy requirements while maintaining the safety and quality of food products.

In conclusion, the future of microwave sterilizer technology is bright, with continued advancements driving improvements in environmental sustainability, regulatory compliance, and operational efficiency. By staying abreast of these trends, food manufacturers can harness the full potential of microwave chalk pastel sterilizing dryer drying machines to meet the demands of the modern market.

References

1. Website: Food Processing Technology

URL: https://www.foodprocessing-technology.com/

2. Website: Food Engineering Magazine

URL: https://www.foodengineeringmag.com/

3. Website: Food Manufacturing Magazine

URL: https://www.foodmanufacturing.com/

4. Website: Packaging Digest

URL: https://www.packagingdigest.com/

5. Website: Food Quality & Safety Magazine

URL: https://www.foodqualityandsafety.com/

Telephone :+86-531-55583139

Telephone :+86-531-55583139 WhatsApp :+86 13256674591

WhatsApp :+86 13256674591 Email :

Email :