The Ultimate Guide To The Sago Microwave Drying Oven In 2024

Advantages of Using A Sago Microwave Drying Oven

1. Enhanced Efficiency:The sago microwave drying oven significantly reduces drying time compared to conventional methods, leading to increased productivity and cost savings. Its rapid heating capabilities enable faster processing of materials, thereby streamlining production processes.

2. Improved Quality:By facilitating uniform heating and precise control over drying parameters, the microwave dryer helps maintain the integrity and quality of the materials. This is particularly crucial for heat-sensitive substances, where traditional drying methods may result in degradation or uneven drying.

Energy Efficiency:With its targeted heating mechanism and shorter processing times, the sago microwave drying oven consumes less energy compared to conventional dryers. This not only reduces operational costs but also aligns with sustainable practices, contributing to environmental conservation.

4. Versatility:The versatility of the microwave drying technology enables it to dry a wide range of materials, including food products, pharmaceuticals, ceramics, and more. Its adaptability to different industries makes it a valuable asset for various manufacturing and processing applications.

What Is Sago Microwave Drying Oven?

The sago microwave drying oven represents a cutting-edge solution for industrial drying applications. Unlike traditional methods that rely on convection or conduction heating, this dryer utilizes microwave radiation to rapidly and uniformly heat the material, facilitating quick evaporation of moisture. By harnessing electromagnetic waves in the microwave spectrum, it ensures thorough drying while preserving the product's quality and integrity.

Working Principle of Sago Microwave Drying Oven?

At the core of the sago microwave drying oven lies a sophisticated mechanism that exploits the dielectric properties of materials. When exposed to microwave radiation, water molecules within the substance oscillate rapidly, generating heat through molecular friction. This heat permeates the material, enabling swift moisture removal from the inside out. Additionally, the oven's precise control systems regulate temperature and power levels, ensuring optimal drying conditions for different products.

Application of Sago Microwave Drying Oven

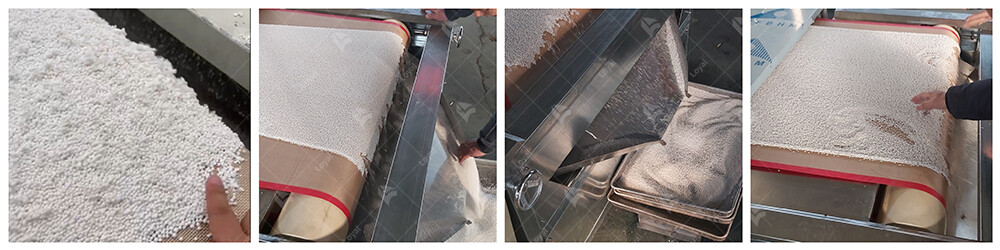

One prominent application of the microwave drying oven is in the food industry, particularly in the processing of sago. Sago, a starchy substance extracted from the pith of various tropical palm trees, requires careful drying to achieve the desired texture and shelf life. Traditional drying methods often result in uneven drying and prolonged processing times. However, with the sago microwave drying oven, manufacturers can achieve rapid and uniform drying, ensuring superior quality sago products.

Additionally, the microwave drying oven finds widespread use in other industries such as pharmaceuticals, ceramics, and chemicals. In pharmaceutical manufacturing, for instance, it facilitates the drying of active pharmaceutical ingredients (APIs) and excipients with precision, maintaining the efficacy of the final drug formulations. Similarly, in the ceramics industry, it enables the drying of clay bodies and glazes, ensuring consistent moisture levels for optimal shaping and firing processes.

Using Microwave Technology to Improve Sago Drying Production Efficiency

In the realm of food processing, efficiency is paramount. Traditional methods of drying sago pearls often involve prolonged drying times and significant energy consumption. However, with the advent of sago microwave drying ovens, the landscape of sago processing has undergone a revolutionary change. These industrial-grade machines utilize the power of microwaves to rapidly and evenly dry sago pearls, thereby boosting production efficiency while maintaining product quality.

Industrial microwave grain dryers represent a significant advancement in sago processing technology. By harnessing the electromagnetic radiation of microwaves, these dryers can penetrate the sago pearls, heating them from the inside out. This results in quicker drying times compared to conventional methods, allowing for higher throughput and reduced energy expenditure.A cornerstone of modern sago processing facilities is the microwave tunnel sabudana pearl tapioca sago drying machine. This specialized equipment features a conveyor belt system that carries the sago pearls through a tunnel-like chamber, where they are exposed to controlled microwave radiation. This continuous process ensures uniform drying throughout the entire batch, leading to consistent product quality.

One of the key advantages of continuous microwave dryers is their ability to operate non-stop, 24/7, maximizing production output. Unlike batch drying methods, which require frequent loading and unloading of the drying chamber, continuous microwave dryers can handle large volumes of sago pearls with minimal downtime.

Moreover, industrial sago microwave systems are designed with efficiency in mind. Advanced controls and sensors allow operators to precisely regulate parameters such as temperature and moisture levels, ensuring optimal drying conditions for different sago varieties. This level of control not only enhances product quality but also reduces waste by minimizing over-drying or under-drying.

In conclusion, the adoption of microwave technology in sago drying processes represents a significant leap forward in terms of efficiency and productivity. With sago microwave drying ovens, industrial microwave grain dryers, microwave tunnel sabudana pearl tapioca sago drying machines, and continuous microwave dryers leading the way, sago producers can achieve higher throughput, lower energy costs, and superior product quality, ultimately driving growth and competitiveness in the industry.

Choosing The Right Machinery of Sago Microwave Drying Oven

When it comes to choosing the right machinery for industrial microwave drying, one must consider several factors, with the sago microwave drying oven being a crucial component. The precise control offered by these ovens allows for customization of drying parameters to meet specific product requirements. Investing in a high-quality sago microwave drying oven can significantly enhance productivity and product quality in sago processing facilities. Therefore, careful consideration should be given to selecting the right machinery, with a focus on incorporating a reliable and efficient sago microwave drying oven into the production process.

Technical Parameters Of Continuous Microwave Dryer Industrial Microwave Drying Machine | |||||

| Model | Size L*W*H(Can be customized according to the customer's requirements) | Output power | Dewaterability | Sterilization capacity | Baking and Roasting capacity (Depends on different raw material) |

| LY-10KW | 5000mm*825mm*1750mm | ≥10KW | 10KG/Hour | 100KG/Hour | 30-50KG/Hour |

| LY-20KW | 8000mm*825mm*1750mm | ≥20KW | 20KG/Hour | 200KG/Hour | 60-100KG/Hour |

| LY-30KW | 8500mm*1160mm*1750mm | ≥30KW | 30KG/Hour | 300KG/Hour | 90-150 KG/Hour |

| LY-40KW | 10000mm*1160mm*1750mm | ≥40KW | 40KG/Hour | 40KG/Hour | 120-200KG/Hour |

| LY-50KW | 12500mm*1160mm*1750mm | ≥50KW | 50KG/Hour | 500KG/Hour | 150-250KG/Hour |

| LY-60KW | 13500mm*1450mm*1750mm | ≥60KW | 60KG/Hour | 600KG/Hour | 180-300KG/Hour |

| LY-70KW | 13500mm*1500mm*1750mm | ≥70KW | 70KG/Hour | 700KG/Hour | 210-350KG/Hour |

| LY-80KW | 13500mm*1650mm*1750mm | ≥80KW | 80KG/Hour | 800KG/Hour | 240-400KG/Hour |

| LY-100KW | 16800mm*1650mm*1750mm | ≥100KW | 100KG/Hour | 1000KG/Hour | 300-500KG/Hour |

| LY-150KW | 22400mm*1850mm*1750mm | ≥150KW | 150KG/Hour | 1500KG/Hour | 450-750KG/Hour |

| LY-200KW | 27000mm*1850mm*1750mm | ≥250KW | 250KG/Hour | 2500KG/Hour | 750-1250/Hour |

| LY-300KW | 32000mm*1850mm*1750mm | ≥300KW | 300KG/Hour | 3000KG/Hour | 900-1500KG/Hour |

Power Supply | 380V±10% 50Hz±1% Three-Phase Five-Wire | ||||

Microwave Output Frequency | 2450±50Mhz | ||||

Microwave Input Apparent Power | ≤168Kva | ||||

Microwave Output Power | ≥120Kw | ||||

Microwave Power Adjustment Range | 0-30Kw(Adjustable) | ||||

Ambient Temperature | -5-40°C | ||||

Relative Humidity | ≤80%, Surrounding Environment:No Corrosive Gas, Conductive Dust And Explosive Gas | ||||

Transmission Speed | 0-10m/Min(Adjustable) | ||||

Understand the Functions of Sago Microwave Dryer

In the realm of food processing, efficiency and quality are paramount. With the evolution of technology, industrial processes have witnessed significant advancements, particularly in drying techniques. One such innovation, gaining prominence in recent years, is the industrial microwave drying oven. This cutting-edge equipment revolutionizes the drying process, especially for delicate food items like sago.

Microwave technology offers a swift and efficient drying solution for sago, addressing the limitations of conventional methods. The microwave tunnel sabudana pearl tapioca sago drying machine ensures uniform drying while preserving the product's nutritional value and sensory attributes. Its ability to penetrate the material evenly accelerates the drying process, significantly reducing processing time.

A standout feature of the continuous microwave dryer is its adaptability to various production scales. Whether in small artisanal setups or large-scale industrial facilities, this equipment ensures consistent drying results. Its versatility makes it an indispensable asset in modern sago processing plants.

The integration of industrial sago microwave systems optimizes production efficiency and quality control. These systems offer precise control over drying parameters, allowing operators to tailor the process according to specific requirements. Moreover, they enhance energy efficiency by minimizing heat loss, making them environmentally friendly alternatives.

In conclusion, the adoption of an industrial microwave dryer signifies a paradigm shift in sago processing. Its ability to streamline operations, improve product quality, and reduce processing time underscores its significance in the food industry. As technology continues to advance, leveraging innovations like microwave drying will be crucial for meeting evolving consumer demands and industry standards.

Selecting The Best Microwave Sago Drying Equipment

When it comes to selecting the best microwave sago drying equipment, one should consider various factors to ensure optimal results. At Loyal, we understand the significance of efficient drying processes, especially when dealing with delicate products like sago. Our sago microwave drying oven is designed with precision and expertise to meet the specific requirements of sago processing. The key advantage of our equipment lies in its ability to provide quick and uniform drying, preserving the quality and nutritional value of the sago pearls. With advanced technology and customizable features, our microwave drying oven offers versatility and reliability, making it the ideal choice for sago manufacturers. Whether you're a small-scale producer or a large-scale operation, Loyal's sago drying equipment guarantees superior performance and consistent output, ultimately enhancing productivity and profitability.

Expertise Of Engineers In Microwave Sago Drying

Microwave drying ovens are revolutionizing the process of drying sago, providing faster and more efficient results compared to traditional methods. At Loyal, our team of engineers specializes in maximizing the sago microwave drying oven technology to deliver superior outcomes. With their expertise, they have fine-tuned the process to ensure optimal drying conditions for sago, preserving its quality and nutritional value. The microwave sago drying process involves carefully controlling parameters such as temperature, humidity, and airflow to achieve the desired moisture content while minimizing energy consumption. Our engineers leverage their deep understanding of microwave technology and sago properties to tailor solutions that meet the unique requirements of our clients. By harnessing the power of microwave technology, we offer a sustainable and cost-effective solution for sago drying that sets new standards in the industry. With Loyal's commitment to innovation and the expertise of our engineers, we continue to push the boundaries of sago microwave drying to deliver superior results for our customers worldwide.

Importance of Quality Control in Microwave Drying Equipment

In the realm of industrial food processing, sago microwave drying oven plays a pivotal role in ensuring efficient production and maintaining product quality. These ovens utilize microwave technology to swiftly and evenly dry various food products, including tapioca pearls, commonly known as sabudana or sago. However, to ensure optimal performance and consistent quality output, it is imperative to implement stringent quality control measures throughout the manufacturing and operation processes of industrial microwave grain dryers.

One of the primary concerns in the production of microwave tunnel sabudana pearl tapioca sago drying machines is the uniformity of drying. Variations in drying time or temperature can result in uneven moisture content within the product, leading to quality defects such as clumping or discoloration. Through meticulous quality control protocols, manufacturers can calibrate and fine-tune these continuous microwave dryers to guarantee precise and uniform drying, thereby upholding the integrity of the final product.

Another crucial aspect of quality control in industrial sago microwave systems is the assurance of safety standards. Microwave technology involves the use of electromagnetic radiation to generate heat, necessitating rigorous safety measures to mitigate potential hazards. By adhering to strict quality control guidelines, manufacturers can ensure that microwave drying equipment complies with regulatory safety standards, safeguarding both product quality and the well-being of personnel involved in the production process.

Moreover, quality control procedures are essential for identifying and rectifying any technical malfunctions or defects in sago microwave drying ovens promptly. Routine inspections and performance evaluations enable early detection of issues such as faulty components or inadequate heating mechanisms, preempting costly downtime and production delays. By prioritizing quality control, manufacturers can uphold the reliability and longevity of their industrial microwave grain dryers, thereby optimizing operational efficiency and minimizing disruptions.

In conclusion, the significance of quality control in microwave drying equipment cannot be overstated. From ensuring uniform drying and adhering to safety standards to detecting and rectifying technical malfunctions, stringent quality control measures are indispensable for maintaining the efficacy and reliability of industrial sago microwave systems. By prioritizing quality at every stage of production and operation, manufacturers can uphold the integrity of their products and sustain long-term success in the competitive food processing industry.

Latest Innovations and Trends in Industrial Microwave Sago Drying

One of the notable trends in industrial microwave sago drying is the integration of advanced control systems for enhanced efficiency and productivity. Manufacturers are incorporating smart sensors and automation technologies to monitor and regulate the drying process in real-time, ensuring optimal results while minimizing energy consumption. This not only streamlines operations but also improves the overall quality and consistency of the dried sago.

Moreover, there has been a significant focus on sustainability in the development of microwave drying solutions for the sago industry. With concerns about environmental impact on the rise, manufacturers are increasingly adopting eco-friendly practices and optimizing energy utilization. This includes the implementation of energy-efficient designs, as well as the utilization of renewable energy sources to power microwave drying operations, thereby reducing carbon footprint and contributing to a greener future.

In addition to technological advancements, there is a growing emphasis on customization and flexibility in industrial microwave sago drying systems. Manufacturers are offering modular designs and customizable features to cater to diverse processing needs and production requirements. This enables sago producers to adapt their drying processes according to specific parameters such as batch size, moisture content, and desired end-product characteristics, thereby maximizing operational efficiency and product quality.

In conclusion, the sago microwave drying oven and industrial microwave grain dryers represent the latest innovations and trends in sago drying, offering unparalleled speed, efficiency, and quality in food processing. With advancements in technology, sustainability, and customization, these cutting-edge solutions are poised to revolutionize the sago industry, meeting the evolving demands of consumers while driving progress towards a more sustainable and efficient future.

Advances in Microwave Drying Equipment

In recent years, sago microwave drying ovens have emerged as a revolutionary solution in the food processing industry. These advanced appliances utilize microwave technology to efficiently remove moisture from sago pearls, ensuring a faster and more uniform drying process compared to traditional methods. The utilization of industrial microwave grain dryers has significantly enhanced productivity in sago processing plants, allowing for continuous and precise drying operations.

One notable innovation in microwave drying equipment is the development of microwave tunnel sabudana pearl tapioca sago drying machines. These state-of-the-art systems feature a tunnel-like structure where sago pearls pass through, exposed to controlled microwave energy for rapid dehydration. This technology has revolutionized the sago drying process, ensuring higher quality end products with minimal energy consumption.

Another breakthrough in microwave drying technology is the introduction of continuous microwave dryers. Unlike batch drying systems, continuous dryers enable a constant flow of sago pearls through the drying chamber, resulting in increased efficiency and throughput. This advancement has proven invaluable for large-scale sago production facilities, where high volumes of product must be processed efficiently to meet market demands.

Furthermore, the integration of industrial sago microwave systems has revolutionized the way sago pearls are dried on an industrial scale. These specialized systems are designed to handle large quantities of sago pearls while maintaining optimal drying conditions. With precise temperature and moisture control, industrial sago microwave systems ensure consistent product quality while reducing processing times and energy costs.

Types of Sago Microwave Drying

1. Batch Microwave Dryers:Batch microwave dryers are suitable for small to medium-scale sago drying operations. In these dryers, sago is placed in trays or containers and exposed to microwave radiation in batches. The moisture content is gradually reduced as the sago absorbs the microwave energy, resulting in quick and uniform drying. Batch microwave dryers are cost-effective and ideal for facilities with limited production capacity.

2. Continuous Microwave Dryers:Continuous microwave dryers are designed for large-scale sago processing plants with high production demands. In these systems, sago moves continuously through a conveyor belt or tunnel while being exposed to microwave radiation. This continuous flow ensures consistent drying and higher throughput compared to batch dryers. Continuous microwave dryers are efficient, reducing processing time and energy consumption in industrial settings.

3. Hybrid Microwave-Infrared Dryers:Hybrid microwave-infrared dryers combine the advantages of both microwave and infrared technologies for sago drying. These dryers use a combination of microwave radiation and infrared heat to achieve rapid and uniform drying. The infrared heat complements the microwave energy, enhancing the overall drying efficiency. Hybrid dryers are versatile and can accommodate variations in sago moisture content and texture, making them suitable for diverse processing requirements.

4. Vacuum Microwave Dryers:Vacuum microwave dryers utilize both microwave radiation and vacuum conditions to dry sago efficiently. By lowering the pressure inside the drying chamber, the boiling point of water decreases, allowing for faster moisture removal from the sago. This method preserves the sago's color, flavor, and nutritional integrity while significantly reducing drying time. Vacuum microwave dryers are particularly suitable for sensitive sago varieties that require gentle processing to maintain quality.

5. Fluidized Bed Microwave Dryers:Fluidized bed microwave dryers are innovative systems that suspend sago particles in a stream of hot air or gas, creating a fluidized bed. Microwave radiation is then applied to the fluidized sago, promoting rapid and uniform drying. These dryers offer excellent heat and mass transfer rates, resulting in efficient moisture removal and shorter drying cycles. Fluidized bed microwave dryers are versatile and can accommodate various sago sizes and shapes, making them ideal for diverse processing needs.

Key Features to Consider in Sago Microwave Drying Oven

The sago microwave drying oven stands out for its ability to rapidly and uniformly dry various materials, including sago pearls, a staple in many Southeast Asian cuisines. Its design incorporates advanced microwave technology to expedite the drying process while maintaining product quality.

1. Microwave Power Control: The ability to adjust microwave power is essential for accommodating different materials and moisture levels. The sago microwave drying oven offers precise control over power settings, ensuring consistent and thorough drying without risking product degradation.

2. Uniform Heating:Achieving uniform heating is critical to prevent hot spots and ensure all parts of the material dry evenly. With its innovative design, the sago microwave drying oven facilitates uniform heat distribution, resulting in high-quality dried products with minimal processing time.

3. Temperature Monitoring and Control:Maintaining the optimal drying temperature is paramount for preserving product integrity and minimizing energy consumption. The sago microwave drying oven is equipped with advanced temperature monitoring and control features, allowing operators to adjust settings in real-time for maximum efficiency.

4. Automatic Process Control:Streamlining operations is key to enhancing productivity and consistency. The sago microwave drying oven offers automatic process control capabilities, reducing the need for manual intervention and ensuring reliable performance batch after batch.

5. Energy Efficiency:In today's eco-conscious world, energy efficiency is a top priority for businesses seeking to minimize their environmental footprint and operational costs. The sago microwave drying oven is engineered for energy efficiency, utilizing microwave technology to deliver rapid drying with lower energy consumption compared to traditional drying methods.

6. Durable Construction:Industrial equipment must withstand rigorous use in demanding environments. The sago microwave drying oven is built to last, featuring durable construction and high-quality components that withstand the rigors of continuous operation.

7. Ease of Maintenance:Simplifying maintenance tasks is essential for minimizing downtime and prolonging equipment lifespan. The sago microwave drying oven is designed for ease of maintenance, with accessible components and user-friendly interfaces that facilitate routine upkeep.

Utilizing YouTube as A Knowledge Source for Dustrial Microwave Sago Drying

Utilizing YouTube as a knowledge source for industrial sago microwave drying oven has become increasingly popular among professionals in the food processing industry. With the rapid advancements in technology, accessing valuable insights and tutorials on efficient sago microwave drying oven techniques has never been easier. By leveraging YouTube's vast library of videos, experts and enthusiasts alike can gain practical knowledge on operating and optimizing sago microwave drying oven equipment. From step-by-step guides on setting up the machinery to troubleshooting common issues, YouTube serves as a comprehensive platform for learning and staying updated on the latest trends in sago microwave drying oven technology. Whether it's exploring innovative methods or mastering the fundamentals, YouTube offers a diverse range of content tailored to meet the needs of both seasoned professionals and newcomers in the field. As the demand for efficient and cost-effective sago microwave drying oven solutions continues to rise, harnessing the power of YouTube as an educational tool proves invaluable for enhancing productivity and achieving optimal results.

References

1. IEEE Xplore (https://ieeexplore.ieee.org/)

2. ScienceDirect (https://www.sciencedirect.com/)

3. SpringerLink (https://link.springer.com/)

4. Wiley Online Library (https://onlinelibrary.wiley.com/)

5. Taylor & Francis Online (https://www.tandfonline.com/)

FAQs: Frequently Asked Questions about sago microwave drying oven

1. Q: Is microwave drying suitable for all types of materials?

A: While microwave drying is highly versatile, certain materials with low dielectric properties may not respond as effectively. However, with proper optimization and customization of parameters, the sago microwave drying oven can accommodate a wide range of substances.

2. Q: How does microwave drying compare to other drying methods in terms of energy consumption?

A: Microwave drying typically consumes less energy than conventional methods due to its direct heating mechanism and shorter processing times. This results in cost savings and reduced carbon footprint, making it a more sustainable choice for industrial applications.

3. Q: Can the sago microwave drying oven be customized to suit specific drying requirements?

A: Yes, the sago microwave drying oven can be tailored to meet the unique needs of different industries and materials. From adjusting power levels and heating patterns to incorporating specialized features, manufacturers offer customization options to optimize drying performance and efficiency.

4. Q: Is maintenance of the sago microwave drying oven complex?

A: Maintenance of the sago microwave drying oven is typically straightforward, involving routine cleaning and inspection of components. Manufacturers often provide comprehensive manuals and support services to assist with upkeep. Additionally, the durable construction and advanced technology of the oven contribute to long-term reliability and minimal maintenance requirements.

5. Q: Are there any safety concerns associated with operating a microwave drying oven?

A: While microwave drying ovens are generally safe when used according to guidelines, certain precautions should be observed. Operators should avoid placing metal objects or materials with metallic components inside the oven to prevent sparking or arcing. Additionally, proper ventilation and safety protocols should be followed to mitigate risks associated with electromagnetic radiation and overheating.

6. Q: What are the typical applications of the sago microwave drying oven?

A: The sago microwave drying oven finds widespread use across various industries, including food processing, pharmaceuticals, ceramics, and textiles. It is employed for drying a diverse range of materials such as grains, herbs, powders, and electronic components, among others. Its versatility and efficiency make it indispensable for achieving precise moisture control and product quality in manufacturing processes.

Telephone :+86-531-55583139

Telephone :+86-531-55583139 WhatsApp :+86 13256674591

WhatsApp :+86 13256674591 Email :

Email :