Sago Microwave Drying Oven Specifications :

| Price | USD 100.000-8,800.00 |

| Brand Name | LOYAL |

| Model Number | LY |

| Place of Origin | CHINA |

| Min.Order Quantity | 1 |

| Payment Terms | T/T, L/C |

| Supply Ability | 30SETS/MONTH |

| Delivery Detail | 30DAYS |

| Packaging Details | Wooden packages |

Sago Microwave Drying Oven Detail Introduction :

SAGO MICROWAVE DRYING OVEN

Sago Microwave Drying Oven: Revolutionizing Tapioca Drying with Industrial Microwave Technology

In the ever-evolving landscape of food processing, the Sago Microwave Drying Oven has emerged as a cutting-edge solution for drying tapioca pearls, bringing efficiency and precision to the forefront. Developed by Shandong Loyal Industrial Co., Ltd., this innovative technology combines the power of Industrial Microwave Grain Dryer with the specificity of Sago drying. Let's explore the working principles, advantages, and address common FAQs surrounding the Sago Microwave Drying Oven.

Working Principles of Industrial Sago Microwave Systems:

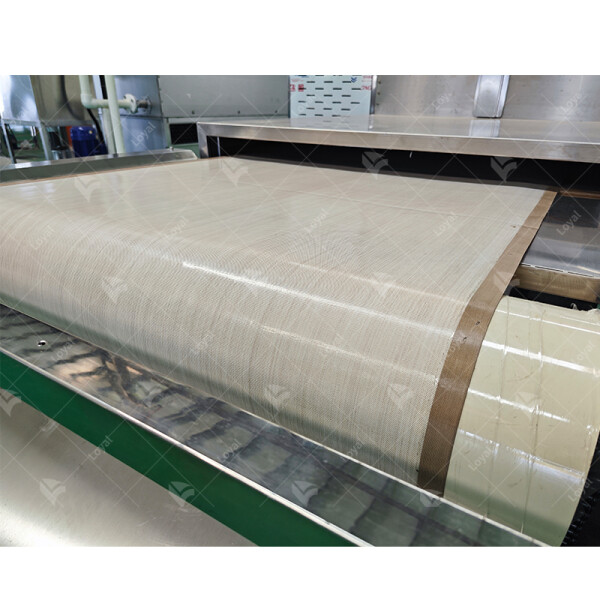

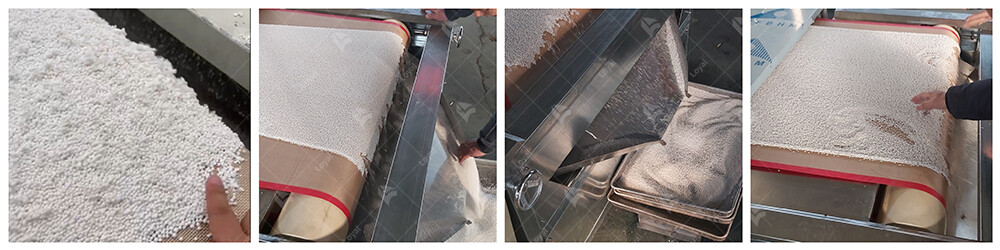

The Industrial Sago Microwave Systems operate on the principle of utilizing microwave energy for the efficient and uniform drying of tapioca pearls. In the heart of the system lies the continuous microwave dryer, where tapioca pearls are conveyed through a tunnel-like structure. The microwave energy is emitted onto the passing tapioca, penetrating the pearls and causing the water molecules within to vibrate rapidly. This rapid vibration generates heat, effectively evaporating the moisture content and leaving behind perfectly dried Sago pearls.

Industrial Microwave Grain Dryer is a crucial component in modern processing facilities across various industries. This advanced drying equipment utilizes microwave technology to efficiently and uniformly remove moisture from a wide range of grains, preserving their nutritional value and texture. Whether it's wheat, corn, or rice, the Industrial Microwave Grain Dryer ensures fast and high-quality drying results.

When it comes to continuous and efficient drying solutions, the Tapioca Sago Drying Machine shines as a top choice. Engineered for continuous operation, this drying machine utilizes microwave energy to swiftly remove moisture from Tapioca Sago, ensuring consistent and high-quality drying results. Its continuous operation design boosts productivity while minimizing energy consumption, making it an ideal choice for industrial-scale production facilities.

The continuous microwave dryer represents a paradigm shift in the drying industry, offering unparalleled speed and efficiency. With its continuous processing capability and precise microwave energy control, this dryer can quickly and uniformly dry various materials, from grains to industrial products. Its ability to maintain product quality while accelerating the drying process makes it indispensable in modern manufacturing processes.

Technical Parameters Of Continuous Microwave Dryer Industrial Microwave Drying Machine | |||||

| Model | Size L*W*H(Can be customized according to the customer's requirements) | Output power | Dewaterability | Sterilization capacity | Baking and Roasting capacity (Depends on different raw material) |

| LY-10KW | 5000mm*825mm*1750mm | ≥10KW | 10KG/Hour | 100KG/Hour | 30-50KG/Hour |

| LY-20KW | 8000mm*825mm*1750mm | ≥20KW | 20KG/Hour | 200KG/Hour | 60-100KG/Hour |

| LY-30KW | 8500mm*1160mm*1750mm | ≥30KW | 30KG/Hour | 300KG/Hour | 90-150 KG/Hour |

| LY-40KW | 10000mm*1160mm*1750mm | ≥40KW | 40KG/Hour | 40KG/Hour | 120-200KG/Hour |

| LY-50KW | 12500mm*1160mm*1750mm | ≥50KW | 50KG/Hour | 500KG/Hour | 150-250KG/Hour |

| LY-60KW | 13500mm*1450mm*1750mm | ≥60KW | 60KG/Hour | 600KG/Hour | 180-300KG/Hour |

| LY-70KW | 13500mm*1500mm*1750mm | ≥70KW | 70KG/Hour | 700KG/Hour | 210-350KG/Hour |

| LY-80KW | 13500mm*1650mm*1750mm | ≥80KW | 80KG/Hour | 800KG/Hour | 240-400KG/Hour |

| LY-100KW | 16800mm*1650mm*1750mm | ≥100KW | 100KG/Hour | 1000KG/Hour | 300-500KG/Hour |

| LY-150KW | 22400mm*1850mm*1750mm | ≥150KW | 150KG/Hour | 1500KG/Hour | 450-750KG/Hour |

| LY-200KW | 27000mm*1850mm*1750mm | ≥250KW | 250KG/Hour | 2500KG/Hour | 750-1250/Hour |

| LY-300KW | 32000mm*1850mm*1750mm | ≥300KW | 300KG/Hour | 3000KG/Hour | 900-1500KG/Hour |

| Power Supply | 380V±10% 50Hz±1% Three-Phase Five-Wire | ||||

| Microwave Output Frequency | 2450±50Mhz | ||||

| Microwave Input Apparent Power | ≤168Kva | ||||

| Microwave Output Power | ≥120Kw | ||||

| Microwave Power Adjustment Range | 0-30Kw(Adjustable) | ||||

| Ambient Temperature | -5-40°C | ||||

| Relative Humidity | ≤80%, Surrounding Environment:No Corrosive Gas, Conductive Dust And Explosive Gas | ||||

| Transmission Speed | 0-10m/Min(Adjustable) | ||||

Advantages of Industrial Microwave Grain Dryer for Sago Drying:

1. Rapid Drying Time:

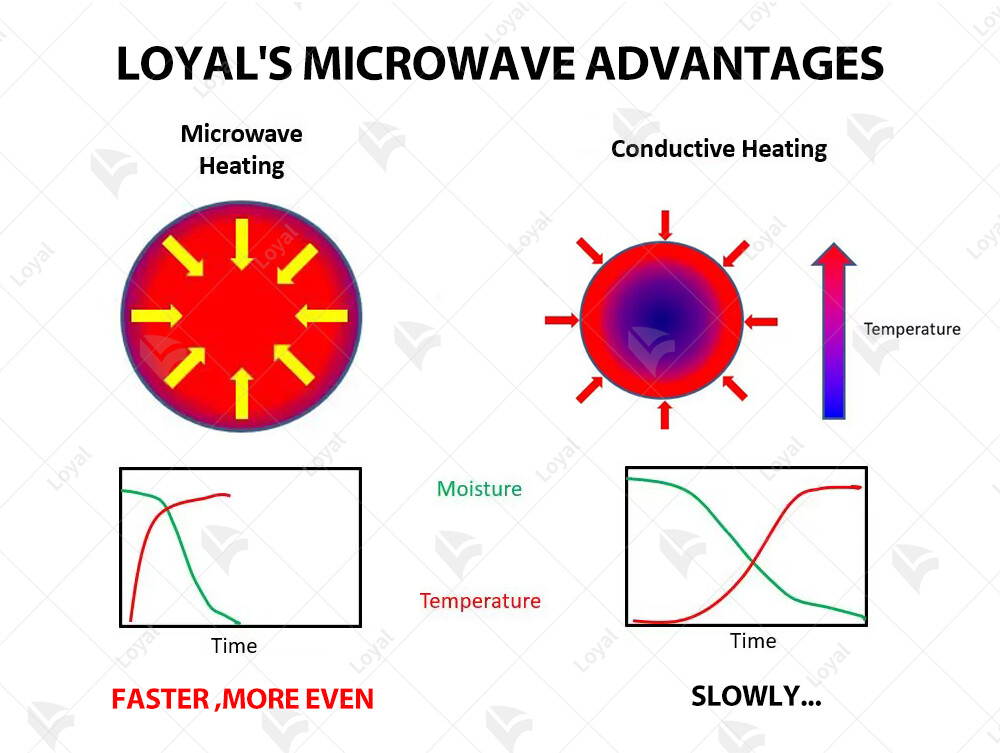

The use of industrial microwaves significantly accelerates the drying process, ensuring a quick turnaround in production. This speed not only enhances efficiency but also allows manufacturers to meet the demands of a dynamic market.

2. Uniform Drying:

Industrial microwave systems offer unparalleled uniformity in drying. The microwave energy is precisely controlled, ensuring that each tapioca pearl undergoes consistent drying, preventing issues such as over-drying or uneven moisture distribution.

3. Energy Efficiency:

Shandong Loyal Industrial Co., Ltd. prioritizes energy efficiency in their designs. The Industrial Microwave Grain Dryer minimizes energy consumption by precisely targeting the moisture within the Sago pearls, reducing overall production costs and environmental impact.

4. Preservation of Quality:

The controlled and rapid nature of microwave drying helps preserve the quality and integrity of tapioca pearls. This is crucial for ensuring that the final product maintains its texture, taste, and appearance.

5. Continuous Operation:

The continuous microwave dryer ensures seamless production, allowing for a continuous flow of Sago pearls through the drying process. This design enhances overall production efficiency and reduces downtime.

FAQs: Common Questions About Sago Microwave Drying Oven:

Q1: Is the Sago Microwave Drying Oven suitable for different sizes of tapioca pearls?

A1: Absolutely. Shandong Loyal Industrial Co., Ltd. designs their systems to be versatile, accommodating various sizes of tapioca pearls. The microwave technology is adjustable to meet the specific requirements of different product lines.

Q2: How does the microwave drying process impact the quality of Sago pearls?

A2: The controlled microwave drying process minimizes the impact on the quality of Sago pearls. It helps retain the natural characteristics of tapioca, ensuring a high-quality final product.

Q3: Are Industrial Sago Microwave Systems environmentally friendly?

A3: Yes, Shandong Loyal Industrial Co., Ltd. prioritizes sustainability. The energy efficiency of their microwave systems reduces overall environmental impact, making them an environmentally friendly choice for Sago drying.

In conclusion, the Sago Microwave Drying Oven from Shandong Loyal Industrial Co., Ltd. showcases the fusion of precision and innovation in tapioca pearl drying. With the advantages of the Industrial Microwave Grain Dryer, this technology is redefining efficiency and quality standards in Sago production. As the food processing industry continues to evolve, Shandong Loyal's commitment to cutting-edge solutions positions the Sago Microwave Drying Oven as a cornerstone for manufacturers seeking optimal results in tapioca processing.

Telephone :+86-531-55583139

Telephone :+86-531-55583139 WhatsApp :+86 13256674591

WhatsApp :+86 13256674591 Email :

Email :