Microwave Chemical Powder Drying Equipment Specifications :

| Price | USD 100.000-8,800.00 |

| Brand Name | LOYAL |

| Model Number | LY |

| Place of Origin | CHINA |

| Min.Order Quantity | 1 |

| Payment Terms | T/T, L/C |

| Supply Ability | 30SETS/MONTH |

| Delivery Detail | 30DAYS |

| Packaging Details | Wooden packages |

Microwave Chemical Powder Drying Equipment Detail Introduction :

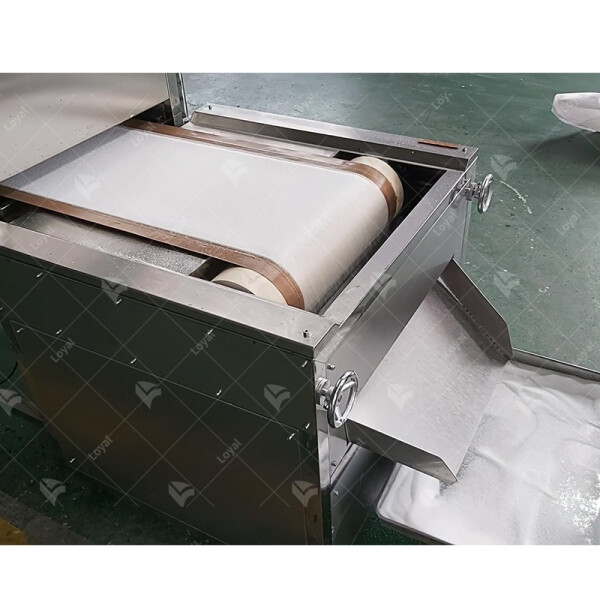

Microwave Chemical Powder Drying Equipment

In the realm of industrial drying, theMicrowave Chemical Powder Drying Equipment from Shandong Loyal Industrial Co., Ltd. stands as a beacon of innovation. This advanced technology is tailored for precision drying of chemical powders, offering a transformative approach to processes involving materials like graphite, silicon carbide, and nano iron oxide. Let's delve into the intricacies of its working principles, advantages, and common FAQs surrounding this cutting-edge equipment.

Working Principles of Microwave Chemical Powder Drying Equipment:

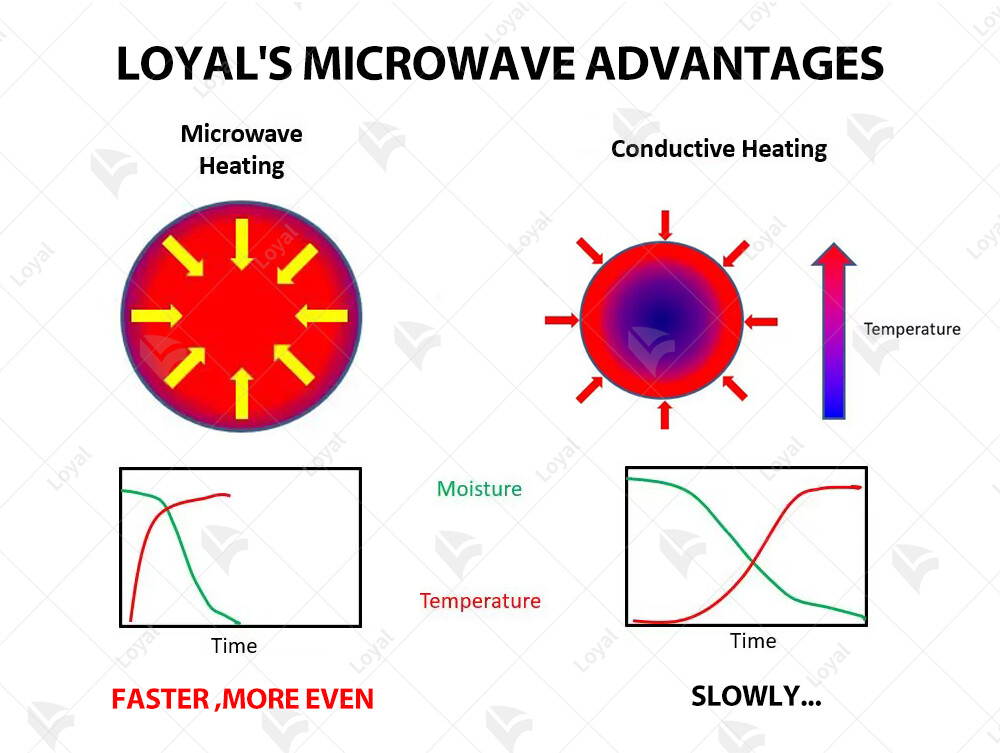

TheMicrowave Chemical Powder Drying Equipmentoperates on the principle of utilizing microwave energy to efficiently and uniformly dry chemical powders. The process begins by placing the chemical powder in the drying chamber. Microwave energy is then emitted, penetrating the powder and causing the water molecules within to vibrate rapidly. This rapid vibration generates heat, facilitating the quick evaporation of moisture from the chemical powder.

Technical Parameters Of Continuous Microwave Dryer Industrial Microwave Drying Machine | |||||

| Model | Size L*W*H(Can be customized according to the customer's requirements) | Output power | Dewaterability | Sterilization capacity | Baking and Roasting capacity (Depends on different raw material) |

| LY-10KW | 5000mm*825mm*1750mm | ≥10KW | 10KG/Hour | 100KG/Hour | 30-50KG/Hour |

| LY-20KW | 8000mm*825mm*1750mm | ≥20KW | 20KG/Hour | 200KG/Hour | 60-100KG/Hour |

| LY-30KW | 8500mm*1160mm*1750mm | ≥30KW | 30KG/Hour | 300KG/Hour | 90-150 KG/Hour |

| LY-40KW | 10000mm*1160mm*1750mm | ≥40KW | 40KG/Hour | 40KG/Hour | 120-200KG/Hour |

| LY-50KW | 12500mm*1160mm*1750mm | ≥50KW | 50KG/Hour | 500KG/Hour | 150-250KG/Hour |

| LY-60KW | 13500mm*1450mm*1750mm | ≥60KW | 60KG/Hour | 600KG/Hour | 180-300KG/Hour |

| LY-70KW | 13500mm*1500mm*1750mm | ≥70KW | 70KG/Hour | 700KG/Hour | 210-350KG/Hour |

| LY-80KW | 13500mm*1650mm*1750mm | ≥80KW | 80KG/Hour | 800KG/Hour | 240-400KG/Hour |

| LY-100KW | 16800mm*1650mm*1750mm | ≥100KW | 100KG/Hour | 1000KG/Hour | 300-500KG/Hour |

| LY-150KW | 22400mm*1850mm*1750mm | ≥150KW | 150KG/Hour | 1500KG/Hour | 450-750KG/Hour |

| LY-200KW | 27000mm*1850mm*1750mm | ≥250KW | 250KG/Hour | 2500KG/Hour | 750-1250/Hour |

| LY-300KW | 32000mm*1850mm*1750mm | ≥300KW | 300KG/Hour | 3000KG/Hour | 900-1500KG/Hour |

| Power Supply | 380V±10% 50Hz±1% Three-Phase Five-Wire | ||||

| Microwave Output Frequency | 2450±50Mhz | ||||

| Microwave Input Apparent Power | ≤168Kva | ||||

| Microwave Output Power | ≥120Kw | ||||

| Microwave Power Adjustment Range | 0-30Kw(Adjustable) | ||||

| Ambient Temperature | -5-40°C | ||||

| Relative Humidity | ≤80%, Surrounding Environment:No Corrosive Gas, Conductive Dust And Explosive Gas | ||||

| Transmission Speed | 0-10m/Min(Adjustable) | ||||

The unique aspect of this equipment lies in its ability to selectively heat the moisture within the powder without significantly affecting the temperature of the material itself. The controlled and precise nature of microwave drying ensures that the chemical powder is dried thoroughly while maintaining its chemical composition and quality.

Industrial Microwave Dryer VS Gas Dryer Comparison

| Operating Conditions | Industrial Microwave Dryer | Direct Fired Gas Dryer(Rotary Drum, Ring, Convection, FlashTypes) |

| Energy Source | Electricity | Gas |

| Heat Penetration | Volumetric(Uniform Throughout | Surface To Interior Conduction |

| Heating Rate | Nearly Instantaneous | Typically Slow |

| Chemical Changes To Product | None | Carbonization, Maillard Reaction, Other |

| Dryness Control/Consistency | Precision ,<1% Possible | Non-Precision,3-5%Typical |

| Color Change To Product | None | May Darken* |

| Nutrient loss in product | None | Possible |

| Reliability | Very High | Poor To Moderate |

| Labor Requirements | Minimal, Fully Automatic | Usually Requires Dedicated Operator |

| Fire/Explosion Hazard* | None | Possible |

| Energy Efficiency | ||

| Overall Energy Efficiency | 75%+ | <50%** |

| Heat Energy Delivered To Load | 95%+ | <50% |

| Water Removal Energy | 1000 - 1200 Btu/ Lb | 1800-2400 Btu/b** |

| 4200-5600 | ||

| 2300-2800 Kj/Kg | Kj/Kg** | |

| Emissions | ||

| Control Equipment Required? | No | Yes |

| Generates Vocs ? | No | Yes |

| Generates Cox And Nox ? | No | Yes |

| Generates Particulates ? | No | Yes |

Advantages ofOurIndustrial Microwave Powder Drying:

- Rapid Drying Time:

The use of industrial microwaves significantly accelerates the drying process, ensuring a quick turnaround in production. This speed not only enhances efficiency but also allows manufacturers to meet the demands of a dynamic market.

- Uniform Drying:

Industrial microwave powder drying offers unparalleled uniformity in drying. The microwave energy is precisely controlled, ensuring each particle undergoes consistent drying, preventing issues such as over-drying or uneven moisture distribution.

3. Preservation of Material Quality:

The controlled and rapid nature of microwave drying helps preserve the quality of chemical powders. This is crucial for ensuring that the final product maintains its chemical properties, ensuring consistency in applications.

4. Energy Efficiency:

Shandong Loyal Industrial Co., Ltd. prioritizes energy efficiency in their designs. The Microwave Chemical Powder Drying Equipment minimizes energy consumption by precisely targeting the moisture within the chemical powder, reducing overall production costs and environmental impact.

5. Versatility in Material Handling:

This equipment is designed to handle a variety of chemical powders, including graphite, silicon carbide, and nano iron oxide. Its versatility makes it suitable for diverse industrial applications.

FAQs: Common Questions About Microwave Chemical Powder Drying Equipment:

Q1: Can the Microwave Chemical Powder Drying Equipment handle materials with different moisture content?

A1: Yes, the equipment is designed to handle a range of moisture content in materials. The microwave drying process can be adjusted to accommodate varying moisture levels.

Q2: Is there any risk of overheating or degradation of chemical properties during the microwave drying process?

A2: No, the controlled and precise nature of microwave drying minimizes the risk of overheating or degradation. It ensures that the chemical properties of the material remain intact.

Q3: How does the equipment ensure uniform drying across a batch of chemical powder?

A3: The industrial microwave system is equipped with advanced technology to ensure uniform energy distribution, guaranteeing that each particle in the batch undergoes consistent and uniform drying.

In conclusion, theMicrowave Chemical Powder Drying Equipment by Shandong Loyal Industrial Co., Ltd. exemplifies a paradigm shift in industrial drying processes. Its innovative use of industrial microwaves not only ensures efficiency and uniformity but also addresses key concerns related to material quality and energy consumption. As manufacturers embrace this cutting-edge technology, the chemical powder processing industry is poised for enhanced quality and productivity, marking a new era in industrial drying.

Telephone :+86-531-55583139

Telephone :+86-531-55583139 WhatsApp :+86 13256674591

WhatsApp :+86 13256674591 Email :

Email :