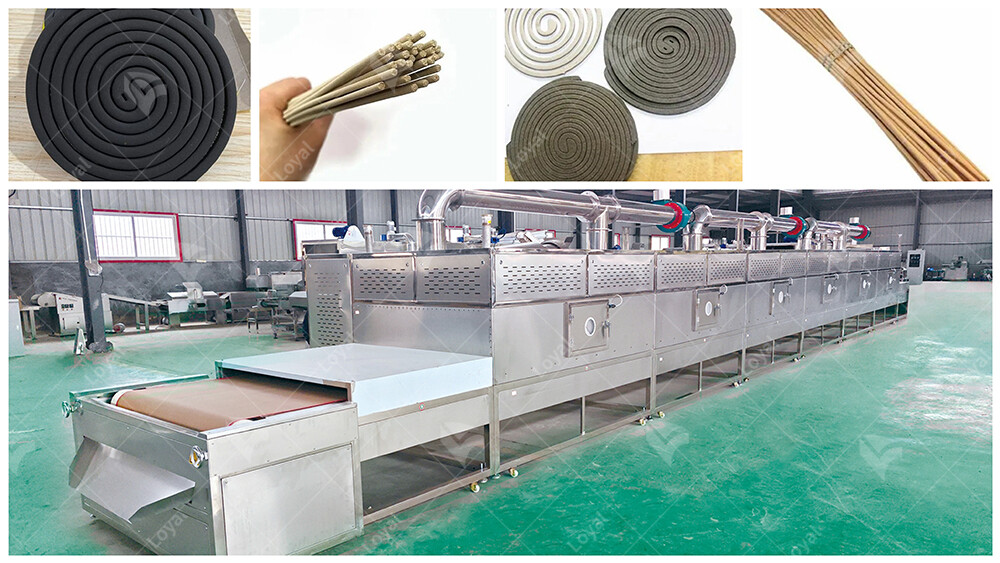

The Ultimate Guide To Mosquito Repellent Microwave Drying Oven In 2024

The difference between microwave drying of mosquito coils and traditional drying of mosquito coils

Microwave drying technology has revolutionized the process of drying mosquito repellent coils, offering numerous advantages over traditional drying methods. The mosquito repellent microwave drying oven utilizes electromagnetic waves to quickly and efficiently remove moisture from the coils, resulting in a faster drying time and higher production efficiency. One key difference between microwave drying of mosquito coils and traditional drying methods lies in the heating mechanism. In traditional drying methods, such as air drying or sun drying, heat is transferred to the coils through convection or radiation, which can be time-consuming and less energy-efficient. On the other hand, the mosquito repellent microwave drying oven heats the coils directly by generating electromagnetic waves, leading to more uniform heating and reduced drying time. Additionally, microwave drying helps preserve the active ingredients in the mosquito repellent coils, ensuring their effectiveness in repelling mosquitoes.

Another important difference between microwave drying of mosquito coils and traditional drying methods is the level of control and precision. With traditional drying methods, such as air drying or sun drying, it can be challenging to control factors such as temperature and humidity, which can impact the quality and consistency of the dried coils. In contrast, the mosquito repellent microwave drying oven allows for precise control over the drying parameters, such as temperature, moisture content, and drying time. This level of control ensures that the mosquito repellent coils are dried to the desired specifications, resulting in consistent quality and performance. Furthermore, microwave drying is a more environmentally friendly option compared to traditional drying methods, as it requires less energy and produces fewer emissions. As a result, the adoption of mosquito repellent microwave drying ovens not only improves the efficiency and quality of mosquito coil production but also contributes to sustainability efforts in the industry.

Working Principle of Mosquito Repellent Microwave Drying Oven

The working principle of the mosquito repellent microwave drying oven is based on the utilization of microwave technology to efficiently remove moisture from mosquito repellent products while maintaining their effectiveness. This specialized drying equipment generates electromagnetic waves that penetrate deep into the repellent material, causing the water molecules to vibrate rapidly and generate heat. As a result, the moisture evaporates from the repellent, leaving behind a dry and potent product. The mosquito repellent microwave drying oven offers several advantages over traditional drying methods, including faster drying times, higher energy efficiency, and better preservation of active ingredients. By harnessing the power of microwave technology, manufacturers can ensure that their mosquito repellent products are thoroughly dried and ready for packaging and distribution.

Key Features to Consider in Mosquito Repellent Microwave Drying Oven

1. Precision Control: One of the essential features to consider in an industrial microwave dryer for mosquito repellents is precision control. This allows operators to adjust parameters such as temperature and humidity with accuracy, ensuring consistent and uniform drying of the repellent products. Precise control is especially critical for maintaining the efficacy of active ingredients in mosquito repellents.

2. Energy Efficiency: Another important factor is energy efficiency. Opting for a mosquito repellent microwave drying oven that utilizes energy-efficient technology can significantly reduce operational costs and environmental impact. Advanced features such as smart sensors and automatic power adjustment help optimize energy consumption during the drying process.

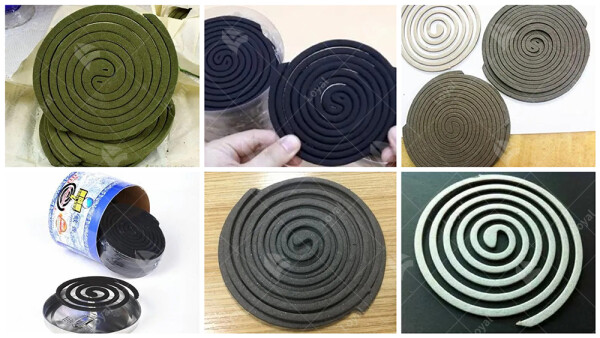

3. Versatility: A versatile microwave drying machine is beneficial for manufacturers producing a variety of mosquito repellent products. Look for dryers that can accommodate different shapes, sizes, and formulations of repellents, including coils, creams, and sprays. Versatility ensures flexibility in production and allows for seamless integration into existing manufacturing processes.

4. Rapid Drying: Speed is often a priority in industrial production settings. Choosing a mosquito repellent industrial microwave dryer with rapid drying capabilities enables manufacturers to increase throughput and meet demanding production schedules. High-speed drying also minimizes the risk of product degradation and ensures consistent product quality.

5. Easy Maintenance: Maintenance plays a crucial role in maximizing the lifespan and efficiency of industrial microwave dryers. Selecting a dryer with easy-to-access components and intuitive maintenance procedures simplifies upkeep tasks and reduces downtime. Additionally, opt for models with self-diagnostic features that alert operators to potential issues before they escalate.

Selecting The Best Mosquito Coil Drying Equipment

When selecting the best mosquito coil drying equipment, companies like Loyal understand the importance of efficiency and effectiveness. Among the various options available, mosquito repellent microwave drying oven stands out as a top choice. These ovens utilize microwave technology to rapidly and evenly dry mosquito coil , ensuring optimal potency and longevity. By harnessing the power of microwave radiation, moisture is quickly removed from the coils, preventing mold and bacterial growth while preserving the active ingredients. Loyal offers state-of-the-art mosquito repellent microwave drying ovens designed to meet the stringent requirements of the mosquito coil industry. With precise temperature control and advanced features, these ovens provide reliable performance and consistent results.

Expertise of Engineers in Microwave Mosquito Coil Drying

Microwave drying technology has revolutionized the process of drying mosquito repellent products such as coils and incense. At Loyal, our engineers possess extensive expertise in utilizing mosquito repellent microwave drying ovens to ensure efficient and effective drying processes.

When it comes to mosquito coil dryers, our engineers are well-versed in the intricacies of this specialized equipment. They understand the importance of precise temperature control and uniform drying to maintain the quality and effectiveness of the final product. With their expertise, they can optimize the operation of mosquito repellent industrial microwave dryers, resulting in higher productivity and consistent product quality.

Moreover, our engineers are proficient in the microwave drying process specific to mosquito repellent products. They are knowledgeable about the unique properties of these materials and how they behave under microwave radiation. By leveraging this understanding, they can tailor the drying parameters to achieve optimal results, such as preserving the potency of active ingredients while minimizing energy consumption.

In addition to mosquito repellent microwave drying technology, our engineers are also adept at utilizing microwave mosquito-repellent incense drying machines. They are experienced in calibrating and operating these machines to meet the exacting standards of our clients.

In conclusion, the expertise of our engineers at Loyal ensures that our microwave drying solutions for mosquito repellent products are cutting-edge and reliable. We are committed to delivering innovative drying solutions that meet the evolving needs of the industry.

Advantages Of Using A Mosquito Repellent Microwave Drying Oven

1. Fast Drying Times: Microwave drying significantly reduces drying times compared to traditional methods, allowing for higher production throughput and faster turnaround.

2. Uniform Drying: The penetration depth of microwave radiation ensures uniform heating throughout the material, eliminating moisture gradients and ensuring consistent product quality.

3. Preservation of Active Ingredients: The gentle heating process of microwave drying helps preserve the efficacy of active ingredients in mosquito repellents, ensuring maximum effectiveness.

4. Energy Efficiency: Microwave drying requires less energy compared to conventional drying methods, contributing to cost savings and environmental sustainability.

5. Compact Design: Microwave drying ovens are often compact and space-efficient, making them suitable for various industrial settings with limited floor space.

Understanding The Role of Industrial Microwave Dryer in Mosquito Coils

In the realm of mosquito repellents, mosquito repellent microwave drying oven plays a crucial role in the production process. Mosquito coils, a common form of mosquito repellent, require careful drying to ensure effectiveness and longevity. This is where microwave mosquito-repellent incense drying machines come into play.

The mosquito repellent industrial microwave dryer utilizes microwave radiation to remove moisture from the mosquito coils efficiently. Unlike conventional drying methods, such as air drying or sun drying, microwave drying offers several advantages. Firstly, it is incredibly fast, reducing drying times significantly. Secondly, it is highly uniform, ensuring that each coil receives consistent treatment. Lastly, it is energy-efficient, leading to cost savings for manufacturers.

The mosquito repellent microwave drying process begins by loading the coils into the drying chamber of the microwave dryer. The chamber is then sealed, and microwave radiation is applied. The moisture within the coils absorbs the microwaves, causing it to evaporate rapidly. As a result, the coils dry evenly and thoroughly, without the risk of over-drying or burning.

One of the key benefits of using an industrial microwave dryer for mosquito coils is its ability to preserve the efficacy of the repellent ingredients. Traditional drying methods, such as high-temperature drying, can degrade the active compounds in the coils, reducing their effectiveness against mosquitoes. However, microwave drying operates at lower temperatures, minimizing the risk of ingredient degradation and ensuring that the coils remain potent.

Furthermore, the use of mosquito repellent microwave drying ovens enables manufacturers to streamline their production processes. With faster drying times and greater control over the drying conditions, manufacturers can increase their output and meet growing demand more efficiently. Additionally, the uniform drying achieved with microwave technology results in higher-quality mosquito coils that provide consistent protection against mosquitoes.

Applications of Mosquito Repellent Microwave Drying Oven

The mosquito repellent microwave drying oven is a revolutionary tool in the fight against mosquitoes. This innovative device utilizes the power of microwaves to quickly and effectively dry mosquito repellent products, ensuring their potency and longevity. With the rise of mosquito-borne illnesses such as malaria and dengue fever, there is an urgent need for reliable mosquito repellent solutions. The mosquito repellent microwave drying oven addresses this need by providing a fast and efficient method for drying mosquito repellent products, allowing them to be distributed to areas where they are most needed.

In the application of industrial microwave dryers, the mosquito repellent microwave drying oven stands out as a crucial tool for manufacturers of mosquito repellent products. By utilizing microwave technology, manufacturers can significantly reduce drying times compared to traditional methods such as air drying or oven drying. This not only increases production efficiency but also ensures that the active ingredients in the mosquito repellent are preserved at their optimal levels.

Furthermore, the mosquito repellent microwave drying oven offers precise control over drying parameters such as temperature and moisture levels, allowing manufacturers to customize the drying process to suit their specific product formulations. This level of control is essential for ensuring the quality and effectiveness of the final mosquito repellent products.

In addition to its applications in mosquito repellent production, the mosquito repellent microwave drying oven also has potential applications in other industries. For example, it could be used to dry various types of herbal products, pharmaceuticals, or even food items. The versatility of this technology makes it a valuable asset for any manufacturing facility looking to optimize their drying processes.

In conclusion, the mosquito repellent microwave drying oven represents a significant advancement in the field of mosquito repellent production. Its ability to quickly and efficiently dry repellent products makes it an indispensable tool for manufacturers looking to combat mosquito-borne illnesses. With its precise control and versatility, this innovative device is sure to play a crucial role in the ongoing fight against mosquitoes and the diseases they carry.

Using Microwave Technology to Improve Mosquito Repellent Drying Production Efficiency

In the realm of pest control and public health, mosquito repellent microwave drying ovens have emerged as a revolutionary solution. Traditional methods of drying mosquito coils and mosquito repellent incense often involve lengthy processes with inconsistent results. However, with the advent of microwave drying technology, manufacturers now have a more efficient and reliable option at their disposal.

Microwave mosquito-repellent incense drying machines are designed to rapidly remove moisture from mosquito repellent products, ensuring a quick turnaround time without compromising effectiveness. By harnessing the power of electromagnetic waves, these drying machines can penetrate the material evenly, resulting in thorough and uniform drying. This not only speeds up production but also enhances the quality of the final product.

The mosquito repellent industrial microwave dryer operates on the principle of dielectric heating, where the water molecules within the mosquito repellent are heated directly. This targeted heating process not only accelerates drying but also minimizes energy consumption compared to conventional drying methods. As a result, manufacturers can significantly reduce production costs while improving overall efficiency.The mosquito repellent microwave drying process begins with loading the mosquito coils or incense into the microwave drying oven. The oven's settings can be adjusted to meet specific drying requirements, such as temperature and duration. Once the process is initiated, the microwave energy quickly heats the product, causing the moisture to evaporate. Within minutes, the mosquito repellent products emerge dry and ready for packaging, eliminating the need for extended drying times associated with traditional methods.

Using microwave technology to improve mosquito repellent drying production efficiency offers numerous advantages for manufacturers. Not only does it streamline the manufacturing process, but it also allows for greater flexibility in production scheduling. Additionally, the consistent and thorough drying achieved through microwave technology ensures that the final products are of the highest quality, enhancing their efficacy in repelling mosquitoes.

Choosing The Right Machinery of Industrial Microwave Dryer

When it comes to choosing the right machinery of industrial microwave dryer, considerations for specialized applications such as mosquito repellent microwave drying ovens are paramount. These ovens offer a fast and efficient method for drying mosquito repellent products while preserving their efficacy. By harnessing the power of microwaves, moisture is rapidly removed from the repellent, ensuring a quick turnaround time for production. Selecting the appropriate microwave drying oven entails assessing factors such as capacity, power output, and drying efficiency to meet the specific needs of the operation. With the proper equipment in place, manufacturers can streamline their production processes and deliver high-quality mosquito repellent products to consumers effectively.

Technical Parameters Of Continuous Microwave Dryer Industrial Microwave Drying Machine | |||||

| Model | Size L*W*H(Can be customized according to the customer's requirements) | Output power | Dewaterability | Sterilization capacity | Baking and Roasting capacity (Depends on different raw material) |

| LY-10KW | 5000mm*825mm*1750mm | ≥10KW | 10KG/Hour | 100KG/Hour | 30-50KG/Hour |

| LY-20KW | 8000mm*825mm*1750mm | ≥20KW | 20KG/Hour | 200KG/Hour | 60-100KG/Hour |

| LY-30KW | 8500mm*1160mm*1750mm | ≥30KW | 30KG/Hour | 300KG/Hour | 90-150 KG/Hour |

| LY-40KW | 10000mm*1160mm*1750mm | ≥40KW | 40KG/Hour | 40KG/Hour | 120-200KG/Hour |

| LY-50KW | 12500mm*1160mm*1750mm | ≥50KW | 50KG/Hour | 500KG/Hour | 150-250KG/Hour |

| LY-60KW | 13500mm*1450mm*1750mm | ≥60KW | 60KG/Hour | 600KG/Hour | 180-300KG/Hour |

| LY-70KW | 13500mm*1500mm*1750mm | ≥70KW | 70KG/Hour | 700KG/Hour | 210-350KG/Hour |

| LY-80KW | 13500mm*1650mm*1750mm | ≥80KW | 80KG/Hour | 800KG/Hour | 240-400KG/Hour |

| LY-100KW | 16800mm*1650mm*1750mm | ≥100KW | 100KG/Hour | 1000KG/Hour | 300-500KG/Hour |

| LY-150KW | 22400mm*1850mm*1750mm | ≥150KW | 150KG/Hour | 1500KG/Hour | 450-750KG/Hour |

| LY-200KW | 27000mm*1850mm*1750mm | ≥250KW | 250KG/Hour | 2500KG/Hour | 750-1250/Hour |

| LY-300KW | 32000mm*1850mm*1750mm | ≥300KW | 300KG/Hour | 3000KG/Hour | 900-1500KG/Hour |

Power Supply | 380V±10% 50Hz±1% Three-Phase Five-Wire | ||||

Microwave Output Frequency | 2450±50Mhz | ||||

Microwave Input Apparent Power | ≤168Kva | ||||

Microwave Output Power | ≥120Kw | ||||

Microwave Power Adjustment Range | 0-30Kw(Adjustable) | ||||

Ambient Temperature | -5-40°C | ||||

Relative Humidity | ≤80%, Surrounding Environment:No Corrosive Gas, Conductive Dust And Explosive Gas | ||||

Transmission Speed | 0-10m/Min(Adjustable) | ||||

Importance of Quality Control in Mosquito Repellent Microwave Drying Oven

Quality control plays a pivotal role in ensuring the efficacy and safety of mosquito repellent microwave drying ovens. The microwave drying oven serves as a crucial tool in the production process of mosquito repellent products, facilitating the rapid and efficient drying of ingredients. However, without stringent quality control measures in place, the integrity of the final product may be compromised.

The importance of quality control in microwave drying equipment cannot be overstated. It encompasses various aspects, including monitoring temperature and humidity levels, ensuring uniformity in drying processes, and conducting regular maintenance checks to prevent equipment malfunctions. By adhering to rigorous quality control protocols, manufacturers can guarantee that their mosquito repellent products meet the highest standards of effectiveness and safety.Furthermore, microwave drying ovens specifically designed for mosquito repellent production must undergo meticulous testing and validation to confirm their ability to achieve optimal drying results while preserving the efficacy of active ingredients. This necessitates collaboration between engineers, researchers, and quality assurance specialists to develop and refine microwave drying techniques tailored to the unique requirements of mosquito repellent formulations.

The integration of robust quality control measures is essential for maximizing the performance and reliability of mosquito repellent microwave drying ovens. By prioritizing quality assurance throughout the manufacturing process, manufacturers can uphold the effectiveness and safety of their products, ultimately contributing to the protection of public health and well-being.

Latest Innovations and Trends in Industrial Microwave Mosquito Coil Drying

One of the latest innovations in the field of industrial microwave mosquito coil drying is the integration of advanced temperature and moisture control systems. These systems allow manufacturers to precisely regulate the drying process, ensuring consistent quality and performance of the final product.

Furthermore, advancements in material science have led to the development of specialized coatings and substrates that enhance the durability and longevity of mosquito repellent coils. These coatings help protect the coils from environmental factors such as humidity and UV radiation, prolonging their effectiveness and shelf life.

In addition to technological innovations, there is a growing trend towards the use of natural and environmentally friendly ingredients in mosquito repellents. Manufacturers are increasingly incorporating botanical extracts and essential oils known for their repellent properties, offering consumers a safer and more sustainable alternative to traditional chemical-based repellents.

Types of Industrial Microwave Dryer for Mosquito Repellent Drying

1. Batch Microwave Drying Ovens:

Batch microwave drying ovens are ideal for small to medium-scale production facilities. They work by exposing batches of mosquito repellent products to microwave radiation in a controlled environment. These ovens offer versatility and can accommodate various shapes and sizes of products.

2. Continuous Microwave Drying Systems:

Continuous microwave drying systems are designed for large-scale production operations. They feature conveyor belts or other automated mechanisms to continuously feed mosquito repellent products into the drying chamber. This type of system ensures a steady flow of production and is highly efficient.

3. Tunnel Microwave Dryers:

Tunnel microwave dryers are another popular choice for mosquito repellent drying. They consist of a tunnel-like chamber through which the products pass on a conveyor belt. Microwave radiation is evenly distributed throughout the tunnel, ensuring uniform drying of the products.

4. Vacuum Microwave Drying Equipment:

Vacuum microwave drying equipment is used for drying mosquito repellent products under reduced pressure. This method helps to lower the boiling point of water, allowing for faster and gentler drying. Vacuum drying also helps to preserve the quality and active ingredients of the repellent.

5. Hybrid Microwave Dryers:

Hybrid microwave dryers combine microwave technology with other drying methods, such as hot air convection or infrared radiation. These systems offer enhanced drying efficiency and flexibility, allowing manufacturers to tailor the drying process to their specific mosquito repellent products.

Routine Maintenance of Mosquito Repellent Microwave Drying Oven

The mosquito repellent microwave drying oven is an essential piece of equipment for effectively drying mosquito repellent products in the manufacturing industry. This specialized oven utilizes microwave technology to quickly and efficiently remove moisture from mosquito repellent materials, ensuring optimal product quality and effectiveness. However, like any other machinery, routine maintenance of the mosquito repellent microwave drying oven is crucial to ensure its smooth operation and longevity. Regular cleaning of the oven interior, checking for any signs of wear or damage, and lubricating moving parts are essential steps in maintaining the efficiency and reliability of the equipment. Additionally, calibration of temperature and moisture sensors is necessary to ensure accurate drying results. By incorporating routine maintenance practices into their operations, manufacturers can maximize the performance and lifespan of their mosquito repellent microwave drying oven, ultimately improving productivity and reducing downtime.

Furthermore, proper training of staff members on the operation and maintenance procedures of the mosquito repellent microwave drying oven is essential to ensure safety and optimal performance. Regular inspections should also be conducted to identify and address any potential issues before they escalate into major problems. Additionally, keeping detailed records of maintenance activities and any repairs performed can help track the history of the equipment and inform future maintenance schedules. By prioritizing routine maintenance and investing in staff training, manufacturers can prolong the lifespan of their mosquito repellent microwave drying oven and maintain consistent production quality.

Utilizing YouTube as A Knowledge Source for Dustrial Microwave Mosquito Coils Drying

Utilizing YouTube as a knowledge source for industrial microwave mosquito coils drying is becoming increasingly popular among manufacturers in the insect repellent industry. Microwave drying ovens offer a rapid and efficient method for drying mosquito coils, ensuring quick turnaround times and maintaining product quality. By searching on YouTube, manufacturers can find a plethora of instructional videos and tutorials that provide insights into the proper operation and optimization of these specialized ovens for mosquito coils drying. These videos offer valuable tips on adjusting temperature and humidity settings, as well as techniques for ensuring uniform drying and preventing product degradation. By leveraging the expertise shared on YouTube, manufacturers can enhance their mosquito coils drying processes, leading to improved productivity and product consistency.

References

1. IEEE Xplore (https://ieeexplore.ieee.org/)

2. ScienceDirect (https://www.sciencedirect.com/)

3. SpringerLink (https://link.springer.com/)

4. Wiley Online Library (https://onlinelibrary.wiley.com/)

5. Taylor & Francis Online (https://www.tandfonline.com/)

FAQs: Frequently Asked Questions About Mosquito Repellent Microwave Drying Oven

1. What types of mosquito repellents can be dried using a microwave drying oven?

Mosquito coils, incense sticks, and other similar products can be effectively dried using a microwave drying oven.

2. Is microwave drying suitable for all types of materials?

While microwave drying is highly versatile, its effectiveness may vary depending on the material's properties. It is essential to consult with experts to determine the suitability of this technology for specific applications.

3. Are microwave drying ovens safe to use?

When operated according to manufacturer guidelines, microwave drying ovens are safe for use. However, proper safety precautions should be followed to prevent accidents or injuries.

4. What are the key considerations when selecting a mosquito repellent microwave drying oven?

When choosing a microwave drying oven for mosquito repellent production, factors such as capacity, power output, control features, and safety measures should be taken into account. It's essential to assess the specific needs and requirements of your production process to ensure compatibility with the chosen equipment.

5. Can microwave drying affect the quality of mosquito repellents?

When properly executed, microwave drying maintains the quality and efficacy of mosquito repellents by preserving their active ingredients. However, inadequate drying conditions or excessive heat exposure can degrade the product's quality. Therefore, it's crucial to optimize drying parameters and monitor the process closely to ensure consistent quality output.

6. How does microwave drying contribute to the efficiency of mosquito repellent production?

Microwave drying offers significant time and energy savings compared to conventional drying methods. Its rapid and uniform heating capabilities enable faster drying cycles, thereby increasing production throughput and reducing operational costs. Additionally, the preservation of active ingredients ensures the production of high-quality mosquito repellents with enhanced effectiveness.

7. Are there any regulatory considerations for using microwave drying in mosquito repellent production?

Depending on the region and specific application, regulatory requirements may apply to the use of microwave drying technology in mosquito repellent production. It's essential to comply with relevant safety standards and regulations governing food and chemical processing to ensure product safety and regulatory compliance.

8. Can microwave drying be combined with other processing techniques for mosquito repellent production?

Yes, microwave drying can be integrated with other processing techniques such as blending, extrusion, or coating to achieve desired product characteristics. By combining multiple techniques, manufacturers can customize the production process to meet specific formulation and performance requirements for mosquito repellents.

Telephone :+86-531-55583139

Telephone :+86-531-55583139 WhatsApp :+86 13256674591

WhatsApp :+86 13256674591 Email :

Email :