The Ultimate Guide to Dried Fish Microwave Sterilization Machine in 2024

Introduction

In 2024, the utilization of Dried Fish Microwave Sterilization Machine marks a significant advancement in the field of food processing technology. This innovative machine combines the power of microwave technology with precision sterilization techniques to ensure the safety and quality of dried fish products. As the demand for safe and high-quality food products continues to rise, understanding the capabilities and benefits of Dried Fish Microwave Sterilization Machine is essential for food manufacturers and consumers alike. This comprehensive guide aims to explore the functionalities, advantages, and applications of Dried Fish Microwave Sterilization Machine, providing invaluable insights into its role in the food processing industry in 2024.

Working principle of microwave sterilizer

The working principle of a Dried Fish Microwave Sterilization Machine is based on the use of microwave radiation to eliminate harmful microorganisms while preserving the quality of dried fish. Inside the sterilization chamber, dried fish is exposed to controlled microwave energy, which penetrates the product and disrupts the cellular structure of any present pathogens. This process effectively deactivates bacteria, viruses, and molds, ensuring the safety and shelf-life of the dried fish product. Additionally, the machine is designed to maintain precise temperature and humidity levels to optimize the sterilization process. Overall, the Dried Fish Microwave Sterilization Machine offers a fast and efficient method for ensuring the safety and quality of dried fish products in 2024.

Advantages of microwave sterilizer

Advantages of Dried Fish Microwave Sterilization Machine |

1. Rapid Sterilization:Microwave technology allows for rapid heating of the dried fish, effectively sterilizing it within minutes. |

2. Uniform Heating:The microwave sterilization process ensures uniform heating throughout the dried fish, eliminating potential cold spots and ensuring thorough sterilization. |

3. Preservation of Nutritional Value:Unlike traditional sterilization methods, microwave sterilization preserves the nutritional value of the dried fish, including vitamins, minerals, and proteins. |

4. Extended Shelf Life:By eliminating harmful microorganisms, the Dried Fish Microwave Sterilization Machine extends the shelf life of the product, reducing the risk of spoilage and foodborne illnesses. |

5. Energy Efficiency:Microwave sterilization is energy-efficient compared to conventional methods, reducing operating costs and environmental impact. |

6. Reduced Processing Time:The quick and efficient sterilization process of the microwave machine reduces overall processing time, allowing for higher production throughput. |

7. Versatility:The Dried Fish Microwave Sterilization Machine can be easily adjusted to accommodate different types and sizes of dried fish, offering versatility in processing various products. |

Key components of microwave sterilizer

Component | Description |

Magnetron | Generates microwave radiation for sterilization. |

Waveguide System | Transmits microwave energy from magnetron to chamber. |

Chamber | Enclosed space where dried fish is placed for sterilization. |

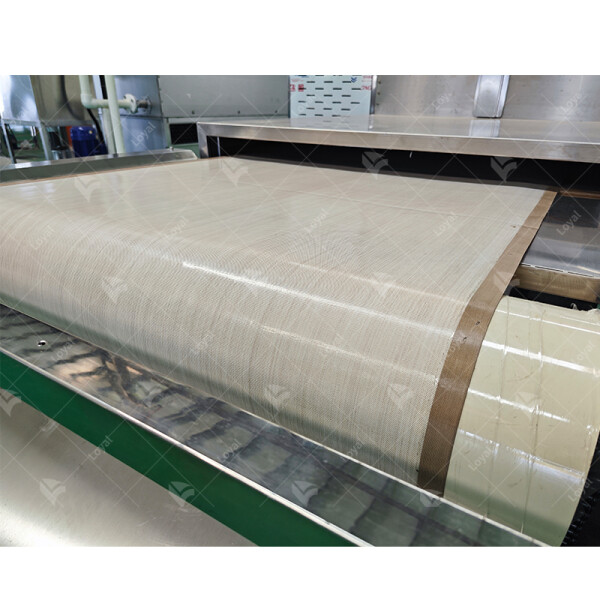

Conveyor System | Moves dried fish through the chamber for uniform exposure to microwaves. |

Temperature Sensor | Monitors and controls the temperature inside the chamber. |

Humidity Sensor | Measures humidity levels to adjust sterilization parameters. |

Control Panel | Interface for setting sterilization parameters and monitoring operation. |

Safety Interlocks | Prevents operation when chamber door is open or if any safety parameters are violated. |

Cooling System | Maintains optimal temperature of magnetron and other components. |

Exhaust System | Removes excess heat and moisture from the chamber. |

Emergency Stop Button | Allows immediate cessation of operation in case of emergencies. |

Comparison and advantages of microwave technology and traditional sterilization methods

Aspect | Microwave Sterilization | Traditional Sterilization |

Sterilization Time | Shorter | Longer |

Temperature Control | Precise | Limited |

Energy Efficiency | Higher | Lower |

Preservation of Nutrients | Better | Reduced |

Uniform Heating | Yes | No |

Moisture Content Control | Better | Limited |

Preservation of Texture | Better | Altered |

Overall Quality of Product | Higher | Lower |

Operating Cost | Potentially Lower | Higher |

Environmental Impact | Reduced | Potential Pollution |

Types of microwave sterilizers

When it comes to dried fish microwave sterilization machines, there are several types available in the market, each offering unique features and functionalities tailored to specific needs and preferences. Below are some common types of microwave sterilizers used for preserving dried fish:

1. Batch Microwave Sterilizers:

Batch microwave sterilizers are designed to process a fixed quantity of dried fish in each batch. They typically feature a chamber where the dried fish is placed on trays or racks, and the sterilization process is carried out within a specified time frame. Batch sterilizers are suitable for small to medium-scale operations and offer flexibility in processing different varieties of dried fish.

2. Continuous Microwave Sterilization Systems:

Continuous microwave sterilization systems are designed for high-volume production of dried fish. They feature a continuous conveyor belt or similar mechanism that moves the dried fish through the sterilization chamber in a continuous flow. This type of sterilizer offers efficient and uninterrupted processing, making it ideal for large-scale operations with high production demands.

3. Tunnel Microwave Sterilization Systems:

Tunnel microwave sterilization systems are a specialized type of continuous sterilizer designed for linear processing of dried fish. They consist of a long tunnel-like chamber through which the dried fish passes on a conveyor belt. Microwave energy is applied uniformly across the length of the tunnel, ensuring consistent and thorough sterilization of the dried fish. Tunnel sterilizers are often used in large-scale production facilities where space is limited, as they can be configured to fit within existing processing lines.

4. Combination Microwave-Hot Air Sterilizers:

Combination microwave-hot air sterilizers combine microwave technology with hot air convection to achieve optimal sterilization of dried fish. These sterilizers use a combination of microwave energy and hot air circulation to penetrate the dried fish and eliminate bacteria, molds, and other pathogens effectively. This type of sterilizer offers the benefits of both microwave and hot air sterilization methods, ensuring thorough and uniform processing of dried fish.

Technical parameters

| Technical Parameters Of Continuous Microwave Dryer Industrial Microwave Drying Machine | |||||

| Model | Size LWH(Can be customized according to the customer's requirements) | Output power | Dewaterability | Sterilization capacity | Baking and Roasting capacity (Depends on different raw material) |

| LY-10KW | 5000mm825mm1750mm | ≥10KW | 10KG/Hour | 100KG/Hour | 30-50KG/Hour |

| LY-20KW | 8000mm825mm1750mm | ≥20KW | 20KG/Hour | 200KG/Hour | 60-100KG/Hour |

| LY-30KW | 8500mm1160mm1750mm | ≥30KW | 30KG/Hour | 300KG/Hour | 90-150 KG/Hour |

| LY-40KW | 10000mm1160mm1750mm | ≥40KW | 40KG/Hour | 40KG/Hour | 120-200KG/Hour |

| LY-50KW | 12500mm1160mm1750mm | ≥50KW | 50KG/Hour | 500KG/Hour | 150-250KG/Hour |

| LY-60KW | 13500mm1450mm1750mm | ≥60KW | 60KG/Hour | 600KG/Hour | 180-300KG/Hour |

| LY-70KW | 13500mm1500mm1750mm | ≥70KW | 70KG/Hour | 700KG/Hour | 210-350KG/Hour |

| LY-80KW | 13500mm1650mm1750mm | ≥80KW | 80KG/Hour | 800KG/Hour | 240-400KG/Hour |

| LY-100KW | 16800mm1650mm1750mm | ≥100KW | 100KG/Hour | 1000KG/Hour | 300-500KG/Hour |

| LY-150KW | 22400mm1850mm1750mm | ≥150KW | 150KG/Hour | 1500KG/Hour | 450-750KG/Hour |

| LY-200KW | 27000mm1850mm1750mm | ≥250KW | 250KG/Hour | 2500KG/Hour | 750-1250/Hour |

| LY-300KW | 32000mm1850mm1750mm | ≥300KW | 300KG/Hour | 3000KG/Hour | 900-1500KG/Hour |

| Power Supply | 380V±10% 50Hz±1% Three-Phase Five-Wire | ||||

| Microwave Output Frequency | 2450±50Mhz | ||||

| Microwave Input Apparent Power | ≤168Kva | ||||

| Microwave Output Power | ≥120Kw | ||||

| Microwave Power Adjustment Range | 0-30Kw(Adjustable) | ||||

| Ambient Temperature | -5-40°C | ||||

| Relative Humidity | ≤80%, Surrounding Environment:No Corrosive Gas, Conductive Dust And Explosive Gas | ||||

| Transmission Speed | 0-10m/Min(Adjustable) | ||||

Application of microwave sterilizers

Application of the Dried Fish Microwave Sterilization Machine in various industries is paramount for ensuring food safety and quality in 2024. This advanced machine utilizes microwave technology to effectively sterilize dried fish, eliminating harmful bacteria and pathogens while preserving the natural flavor and nutritional integrity of the product.

Food Industry:

In the food industry, the Dried Fish Microwave Sterilization Machine plays a crucial role in processing dried fish products. It ensures that dried fish are free from contaminants and safe for consumption, meeting stringent food safety standards. Whether it's for commercial production or small-scale operations, this machine offers a reliable and efficient solution for sterilizing dried fish.

Seafood Processing Plants:

Seafood processing plants rely on the Dried Fish Microwave Sterilization Machine to ensure the safety and quality of their products. By effectively sterilizing dried fish, this machine helps seafood processors maintain high standards of hygiene and comply with regulatory requirements. It also enables them to extend the shelf life of dried fish products, reducing waste and maximizing profitability.

Export and Import Businesses:

Exporters and importers of dried fish rely on the Dried Fish Microwave Sterilization Machine to meet international food safety regulations and quality standards. This machine ensures that dried fish products maintain their quality during transit and storage, minimizing the risk of spoilage or contamination. It provides exporters with a competitive edge in the global market by offering safe and high-quality dried fish products to consumers worldwide.

Retail and Consumer Markets:

In retail and consumer markets, the Dried Fish Microwave Sterilization Machine plays a critical role in ensuring the safety and quality of dried fish products on supermarket shelves and in households. Consumers rely on this technology to provide them with safe and nutritious dried fish options that are free from harmful bacteria and pathogens. The machine's ability to preserve the natural taste and texture of dried fish enhances the overall eating experience for consumers.

Precautions for selection and implementation of microwave sterilizers

When selecting and implementing a Dried Fish Microwave Sterilization Machine, several precautions must be taken into consideration to ensure optimal performance and food safety standards.

1. Compliance with Regulations: Ensure that the microwave sterilizer complies with relevant regulations and standards for food processing equipment. Verify that it meets all necessary health and safety requirements to prevent contamination and ensure the quality of dried fish products.

2. Capacity and Throughput: Consider the capacity and throughput requirements of your production line when selecting a microwave sterilization machine. Choose a machine that can accommodate the volume of dried fish you need to process efficiently without compromising on quality or safety.

3. Energy Efficiency: Opt for a microwave sterilizer that is energy-efficient to minimize operational costs and reduce environmental impact. Look for features such as adjustable power settings and automatic shut-off mechanisms to optimize energy usage during sterilization cycles.

4. Technology and Innovation: Stay updated on the latest advancements in microwave sterilization technology and select a machine that incorporates innovative features for enhanced performance. Look for features such as advanced control systems, real-time monitoring capabilities, and customizable sterilization parameters to improve efficiency and consistency.

5. Maintenance and Support: Choose a microwave sterilization machine from a reputable manufacturer that offers comprehensive maintenance and support services. Ensure that technical assistance, spare parts availability, and training programs are readily accessible to facilitate smooth operation and minimize downtime.

6. Validation and Testing: Prior to full-scale implementation, validate the performance of the microwave sterilizer through rigorous testing procedures. Conduct trials with representative samples of dried fish to assess the effectiveness of the sterilization process and verify compliance with microbiological safety standards.

7. Integration with Existing Equipment: Ensure seamless integration of the microwave sterilizer with existing production equipment and processes. Coordinate with suppliers and manufacturers to optimize workflow efficiency and minimize disruptions during installation and commissioning.

Challenges and limitations of microwave sterilizers

When it comes to microwave sterilizers, there are certain challenges and limitations that must be addressed to ensure optimal performance and effectiveness, particularly in the context of sterilizing dried fish.

1. Uneven Heating: One of the primary challenges faced by microwave sterilizers is the potential for uneven heating. Dried fish, with its varying thickness and density, may not heat uniformly in the microwave, leading to areas that are under-sterilized or over-sterilized. This can compromise the safety and quality of the final product.

2. Moisture Content: Another limitation of microwave sterilizers is their sensitivity to moisture content. Dried fish may contain varying levels of moisture, which can affect how it absorbs microwave energy and undergoes sterilization. High moisture content can result in uneven heating and potentially lead to a less effective sterilization process.

3. Packaging Constraints: The packaging of dried fish can also pose challenges for microwave sterilizers. Certain packaging materials may not be microwave-safe or may interfere with the penetration of microwaves, affecting the overall sterilization process. Additionally, the packaging design must allow for adequate airflow to ensure proper heat distribution.

4. Temperature Control: Maintaining precise temperature control is essential for effective sterilization, but it can be challenging with microwave sterilizers. Dried fish may heat up quickly in certain areas, leading to localized overheating and potentially compromising the texture and flavor of the product. Ensuring consistent temperature distribution throughout the sterilization process is critical for achieving the desired results.

5. Equipment Maintenance: Like any machinery, microwave sterilizers require regular maintenance to ensure optimal performance. However, maintaining microwave sterilizers can be complex due to their intricate design and reliance on sophisticated technology. Failure to properly maintain the equipment can result in decreased efficiency and effectiveness in sterilizing dried fish.

References

The following are five authoritative foreign literature websites in the field of industrial microwaves:

1. IEEE Xplore Digital Library

Website: [https://ieeexplore.ieee.org/]

2.ScienceDirect

Website: [https://www.sciencedirect.com/]

3. SpringerLink

Website: [https://link.springer.com/]

4. Wiley Online Library

Website: [https://onlinelibrary.wiley.com/]

5. PubMed

Website: [https://pubmed.ncbi.nlm.nih.gov/]

Telephone :+86-531-55583139

Telephone :+86-531-55583139 WhatsApp :+86 13256674591

WhatsApp :+86 13256674591 Email :

Email :