Everything you Need to Know About Jujube Tunnel Type Microwave Drying Machine

Introduction to Microwave Drying Technology

Microwave drying technology revolutionizes the food processing industry by offering efficient and rapid drying solutions. Jujube Tunnel Type Microwave Drying Machine is at the forefront of this innovation, utilizing electromagnetic waves to dehydrate food products effectively. Unlike traditional drying methods that rely on convection or conduction, microwave drying applies electromagnetic energy directly to the food material, accelerating the moisture removal process.

Microwave drying machines are equipped with a cavity where the food material is placed for drying. Inside this cavity, microwave radiation is generated, creating a heating effect within the jujube fruits. This targeted heating ensures uniform drying and preserves the quality of the final product. Additionally, jujube tunnel type microwave drying machines are designed with advanced control systems to regulate parameters such as temperature, humidity, and drying time, optimizing the drying process for maximum efficiency.

Understanding Jujube Drying Processes

Jujube drying is a crucial step in the production of jujube-based products, including snacks, candies, and beverages. Traditional drying methods such as sun drying or hot air drying are commonly used but have limitations in terms of efficiency and product quality. In contrast, microwave drying offers several advantages for jujube processing.

The jujube tunnel type microwave drying machine employs a tunnel-like structure where the jujube fruits are conveyed through the drying chamber. Inside the chamber, microwaves penetrate the jujube fruits, causing the water molecules to oscillate and generate heat. This heat evaporates the moisture within the fruits, leading to rapid drying.

Microwave drying also offers precise control over the drying parameters, allowing operators to adjust factors such as temperature, power level, and conveyor speed according to the specific requirements of the jujube product. This flexibility ensures consistent drying results and enables manufacturers to meet quality standards consistently.

Moreover, microwave drying is a continuous process, enabling high throughput and reducing processing time compared to batch drying methods. This increased productivity translates to cost savings and improved efficiency for jujube processing facilities. Overall, understanding the jujube drying processes and the benefits of microwave technology is essential for optimizing production and delivering high-quality jujube products to consumers.

Advantages of Tunnel Type Microwave Drying

Tunnel type microwave drying offers several advantages over traditional drying methods, making it a preferred choice in industrial food processing.

Firstly, Jujube Tunnel Type Microwave Drying Machine ensures rapid and uniform drying of jujube fruits. Unlike conventional methods like sun drying or hot air drying, microwave drying utilizes electromagnetic waves to penetrate the jujube fruits, resulting in faster and more consistent drying rates. This leads to higher production efficiency and throughput.

Secondly, microwave drying helps in preserving the quality and nutritional value of jujube fruits. The controlled and precise heating process minimizes heat exposure, thereby retaining essential nutrients, vitamins, and flavors in the dried jujube products. This is particularly crucial in the food industry, where maintaining product quality is paramount for consumer satisfaction.

Furthermore, tunnel type microwave drying machines are energy-efficient. The technology allows for targeted heating, reducing energy consumption compared to traditional methods that often involve prolonged heating processes. This not only lowers operational costs but also contributes to environmental sustainability by reducing carbon emissions and energy wastage.

Additionally, microwave drying offers versatility and flexibility in processing various jujube products. Whether it's drying whole fruits, slices, or pastes, tunnel type microwave drying machines can be tailored to meet different processing requirements. This adaptability enhances the efficiency and versatility of jujube processing lines, allowing manufacturers to meet diverse market demands effectively.

Components of Jujube Tunnel Type Microwave Drying Machine

The Jujube Tunnel Type Microwave Drying Machine comprises several essential components that work together to facilitate the drying process efficiently.

Firstly, the microwave generator produces electromagnetic waves at specific frequencies, typically around 2450 MHz, which are absorbed by the jujube fruits. These waves penetrate the fruits and cause water molecules to vibrate, generating heat and facilitating the drying process.

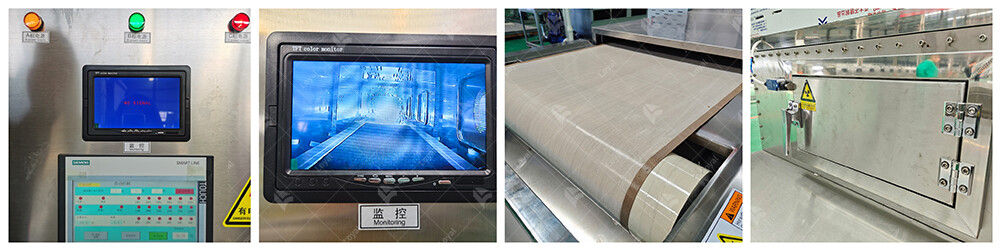

Secondly, the tunnel structure provides a controlled environment for the drying operation. It consists of a conveyor belt system that carries the jujube fruits through the drying chamber at a predetermined speed. The tunnel design ensures uniform exposure to microwave energy, resulting in consistent drying outcomes.

Moreover, the ventilation system plays a crucial role in regulating temperature and humidity levels within the drying chamber. It helps dissipate excess heat and moisture generated during the drying process, maintaining optimal drying conditions and preventing overheating or uneven drying.

Additionally, the control panel enables operators to monitor and adjust various parameters such as microwave power, conveyor speed, and temperature settings. This ensures precise control over the drying process, allowing for customization according to specific jujube varieties and desired product characteristics.

Overall, these components work in tandem to optimize the drying efficiency and quality of jujube fruits, making the Jujube Tunnel Type Microwave Drying Machine an indispensable asset in the food processing industry.

Working Principle of Microwave Drying

Microwave drying is a sophisticated process employed in various industries, including food processing. It involves the utilization of electromagnetic waves to heat and evaporate moisture within the material being dried. In the context of jujube drying, the working principle of a Jujube Tunnel Type Microwave Drying Machine revolves around the generation of microwave energy within a specialized chamber.

The Jujube Tunnel Type Microwave Drying Machine consists of a tunnel-like structure where jujubes are placed on a conveyor belt. Microwave emitters installed within the chamber emit electromagnetic waves, specifically targeting the moisture within the jujubes. These waves penetrate the jujubes and cause the water molecules to vibrate, generating heat. As a result, the moisture evaporates from the surface and within the jujubes, leading to effective drying.

This process is carefully controlled to ensure uniform drying and prevent overheating or burning of the jujubes. The machine is equipped with sensors and controls to monitor parameters such as temperature and moisture levels. By adjusting the intensity and distribution of microwave energy, operators can optimize the drying process for maximum efficiency and quality.

Overall, the working principle of a Jujube Tunnel Type Microwave Drying Machine relies on the precise application of microwave energy to remove moisture from jujubes efficiently and effectively.

Quality Control in Jujube Drying

Quality control is paramount in jujube drying to ensure the final product meets safety and quality standards. The use of a Jujube Tunnel Type Microwave Drying Machine offers several advantages in this regard. Firstly, the controlled and uniform heating provided by microwave technology helps maintain the nutritional content, flavor, and appearance of the jujubes.

Additionally, the machine's monitoring systems enable real-time tracking of key parameters such as moisture content and temperature. This allows operators to make immediate adjustments to optimize drying conditions and prevent issues such as uneven drying or over-drying, which can compromise the quality of the jujubes.

Furthermore, the enclosed design of the drying chamber minimizes the risk of contamination from external sources, ensuring hygienic processing. Regular maintenance and cleaning of the machine also contribute to maintaining product quality and safety.

In conclusion, quality control measures implemented during jujube drying with a Jujube Tunnel Type Microwave Drying Machine are essential for producing high-quality, safe, and nutritious dried jujube products.

Safety Measures for Microwave Drying

Safety is paramount when operating a Jujube Tunnel Type Microwave Drying Machine. One crucial safety measure is proper training for personnel. All operators should receive comprehensive training on how to operate the machine safely, including understanding emergency shutdown procedures. Additionally, personnel should be educated on potential hazards associated with microwave drying, such as electrical shocks and burns.

Another essential safety measure is regular maintenance and inspection of the drying machine. This includes checking for any loose or damaged components, ensuring all safety features are functional, and verifying that the machine is properly grounded. Routine maintenance helps prevent malfunctions that could lead to accidents or injuries during operation.

Furthermore, it's vital to establish clear safety protocols and procedures for handling jujube products during the drying process. This includes guidelines for loading and unloading the machine, as well as protocols for dealing with spills or other emergencies. Proper handling procedures minimize the risk of accidents and ensure the safety of personnel working with the equipment.

Finally, implementing safety equipment and protective gear is essential for minimizing risks during microwave drying. This may include personal protective equipment such as gloves, aprons, and safety goggles to protect against potential hazards. Additionally, installing safety interlocks and emergency stop buttons on the drying machine provides operators with quick and easy ways to halt operations in case of emergencies, enhancing overall safety.

Applications of Jujube Tunnel Type Microwave Drying

The applications of Jujube Tunnel Type Microwave Drying Machines are diverse and expansive. One primary application is in the food processing industry for drying jujube fruits. These machines offer efficient and uniform drying, preserving the flavor, color, and nutritional value of the jujube fruit. The dried jujubes can then be used in various food products such as snacks, candies, and baked goods.

Additionally, Jujube Tunnel Type Microwave Drying Machines find applications in the pharmaceutical industry for drying medicinal herbs and botanicals. The precise control and uniform heating provided by these machines ensure that delicate herbs are dried gently and effectively, preserving their therapeutic properties.

Moreover, these drying machines are also utilized in the agricultural sector for drying jujube leaves, flowers, and seeds. By carefully controlling the drying process, these machines help maintain the quality and potency of jujube-derived agricultural products, which are used in traditional medicine and herbal supplements.

Furthermore, Jujube Tunnel Type Microwave Drying Machines have applications in research and development laboratories for drying samples and materials. The precise control over temperature and moisture content allows researchers to dry sensitive materials without compromising their integrity, making these machines invaluable tools in various scientific disciplines.

Economic Benefits of Microwave Drying Technology

Microwave drying technology, especially in the context of jujube processing, offers significant economic advantages. Firstly, the efficiency of jujube tunnel type microwave drying machines leads to reduced processing time and increased production capacity. This means higher throughput and potentially lower labor costs per unit of dried jujube. Additionally, microwave drying typically requires less energy compared to traditional drying methods, resulting in lower operational costs and improved overall cost-effectiveness.

Furthermore, the quality of the final product obtained from jujube tunnel type microwave drying machines is often superior. This higher quality can command premium prices in the market, thus increasing the profitability of jujube processing operations. Moreover, microwave drying technology enables precise control over the drying process, reducing the risk of product spoilage and waste. This aspect is crucial for maximizing the economic efficiency of jujube processing businesses.

In summary, the economic benefits of adopting jujube tunnel type microwave drying machines are substantial. From increased production efficiency and reduced operational costs to improved product quality and minimized waste, the economic advantages are clear. Investing in microwave drying technology can lead to significant long-term cost savings and enhanced profitability for jujube processing enterprises.

Future Trends in Jujube Drying Machinery

The future of jujube drying machinery is expected to be driven by technological advancements aimed at further improving efficiency, quality, and sustainability. One prominent trend is the integration of smart technologies and automation into jujube tunnel type microwave drying machines. These advancements enable real-time monitoring and control of the drying process, optimizing performance and reducing the need for manual intervention.

Another emerging trend is the development of jujube drying machinery with enhanced energy efficiency and sustainability features. This includes the use of renewable energy sources, such as solar power, to supplement or replace traditional energy sources in microwave drying operations. Additionally, research is underway to explore innovative drying techniques and equipment designs that minimize environmental impact while maximizing drying efficiency.

Furthermore, there is growing interest in the development of jujube drying machinery that is adaptable to different scales of production, from small-scale artisanal operations to large commercial facilities. This flexibility allows jujube processing businesses to tailor their drying operations to specific market demands and production requirements, enhancing overall competitiveness and profitability.

In conclusion, the future of jujube drying machinery is characterized by advancements in technology, sustainability, and flexibility. By embracing these trends, jujube processing enterprises can stay ahead of the curve and position themselves for long-term success in the dynamic global marketplace.

FAQs: Frequently asked questions about Jujube Tunnel Type Microwave Drying Machine

1. What is a Jujube Tunnel Type Microwave Drying Machine?

A Jujube Tunnel Type Microwave Drying Machine is an industrial equipment used to dry jujube fruit using microwave technology. It typically consists of a tunnel-shaped chamber through which jujubes pass on a conveyor belt while being exposed to microwave radiation, facilitating rapid and efficient drying.

2. How does a Jujube Tunnel Type Microwave Drying Machine work?

The machine utilizes microwave radiation to heat the moisture within the jujube fruit, causing it to evaporate and thereby drying the fruit. The tunnel-shaped design ensures uniform exposure of the jujubes to microwave energy, resulting in consistent and thorough drying.

3. What are the advantages of using a Jujube Tunnel Type Microwave Drying Machine?

One key advantage is the speed of drying, as microwave technology can significantly reduce drying times compared to traditional methods. Additionally, microwave drying helps preserve the natural color, flavor, and nutritional content of the jujube fruit. Moreover, these machines are often energy-efficient and offer precise control over the drying process.

4. Are there any safety considerations when using a Jujube Tunnel Type Microwave Drying Machine?

Safety measures should be followed to prevent potential hazards associated with microwave radiation. Proper training on the operation of the machine and adherence to safety protocols are essential. Additionally, regular maintenance and inspection of the equipment are necessary to ensure safe and efficient operation.

References

The following are five authoritative foreign literature websites in the field of industrial microwaves:

1. IEEE Xplore Digital Library

Website: [https://ieeexplore.ieee.org/]

2.ScienceDirect

Website: [https://www.sciencedirect.com/]

3. SpringerLink

Website: [https://link.springer.com/]

4. Wiley Online Library

Website: [https://onlinelibrary.wiley.com/]

5. PubMed

Website: [https://pubmed.ncbi.nlm.nih.gov/]

Telephone :+86-531-55583139

Telephone :+86-531-55583139 WhatsApp :+86 13256674591

WhatsApp :+86 13256674591 Email :

Email :