Everything you Need to Know About Fennel Drying Food Microwave Dryer

Exploring the Science of Fennel Drying Food Microwave Dryer

Fennel Drying Food Microwave Dryer is a sophisticated process that relies on the principles of electromagnetic radiation to remove moisture from various food products, including fennel. This method of drying involves exposing the food to microwave energy, which penetrates the material and heats it from the inside out. The moisture within the food absorbs the energy and evaporates, resulting in the drying of the product. Industrial microwave dryers are specifically designed to optimize this process, ensuring efficient and uniform drying of fennel and other food items.

One of the key advantages of Fennel Drying Food Microwave Dryer is its ability to preserve the quality and nutritional content of the food. Unlike traditional drying methods, such as hot air drying, which can cause degradation of nutrients and flavor, microwave drying allows for gentle and controlled removal of moisture. This helps retain the natural color, texture, and taste of fennel, making it more appealing to consumers. Additionally, industrial microwave dryers offer faster drying times compared to conventional methods, leading to increased productivity and throughput in food processing operations.

In conclusion, Fennel Drying Food Microwave Dryer is a scientifically advanced method of drying food products like fennel. By harnessing the power of electromagnetic radiation, industrial microwave dryers offer efficient, uniform, and gentle drying while preserving the quality and nutritional value of the food. With its energy efficiency and versatility, this technology plays a crucial role in modern food processing operations.

The Evolution of Microwave Technology in Food Industry

The use of microwave technology in the food industry has undergone significant evolution over the years, revolutionizing various aspects of food processing, including drying. Initially introduced for domestic cooking purposes, microwaves were soon recognized for their potential in industrial applications. Early industrial microwave systems were primarily used for heating and thawing food products, offering fast and convenient processing capabilities.

However, as research and development progressed, the potential of microwave technology for drying food products like fennel became apparent. Industrial microwave dryers were developed to address the limitations of traditional drying methods, offering advantages such as faster drying times, better product quality, and energy efficiency. This led to widespread adoption of microwave drying technology across the food industry, particularly in sectors requiring gentle and uniform drying of sensitive products.

Over time, advancements in microwave technology have further enhanced the capabilities of industrial microwave dryers. Improved design features, such as multi-mode heating and precise temperature control, have made these dryers more versatile and effective in meeting the diverse needs of food manufacturers. Additionally, innovations in microwave generator technology have increased the efficiency and reliability of industrial microwave systems, leading to higher productivity and reduced operating costs.

In conclusion, the evolution of microwave technology in the food industry has paved the way for significant advancements in food processing, including drying. From its humble beginnings as a domestic appliance, microwaves have evolved into sophisticated industrial tools capable of delivering efficient, uniform, and high-quality drying of food products like fennel. With ongoing research and innovation, the future holds even greater potential for the continued growth and development of microwave technology in the food industry.

Understanding the Role of Industrial Microwave Dryers

Industrial microwave dryers play a crucial role in the food processing industry, particularly in the drying of various food products like fennel. These dryers utilize microwave radiation to remove moisture from food items efficiently and quickly. Unlike conventional drying methods, industrial microwave dryers offer several advantages, including faster drying times, uniform heating, and better preservation of food quality and nutrients.

The key principle behind industrial microwave dryers is the interaction between electromagnetic waves and water molecules present in the food. When exposed to microwave radiation, water molecules in the food absorb the energy, causing them to vibrate and generate heat. This heat then evaporates the moisture, leading to the drying of the food product. Industrial microwave dryers are designed to control the intensity and distribution of microwave energy to ensure optimal drying conditions for different food items, including fennel.

In industrial settings, these dryers are integrated into food processing lines to streamline the drying process and enhance overall productivity. They are commonly used in facilities involved in the production of dried herbs, spices, fruits, and vegetables, including fennel. Industrial microwave dryers offer precise temperature and moisture control, allowing manufacturers to achieve desired drying outcomes consistently. Additionally, these dryers are versatile and can accommodate various food product sizes and shapes, making them suitable for large-scale production operations.

Overall, industrial microwave dryers play a pivotal role in the food industry by providing efficient and effective drying solutions for a wide range of food products, including fennel. Their ability to deliver rapid and uniform drying results while maintaining food quality makes them indispensable tools in modern food processing operations.

Fennel Drying Techniques in Industrial Settings

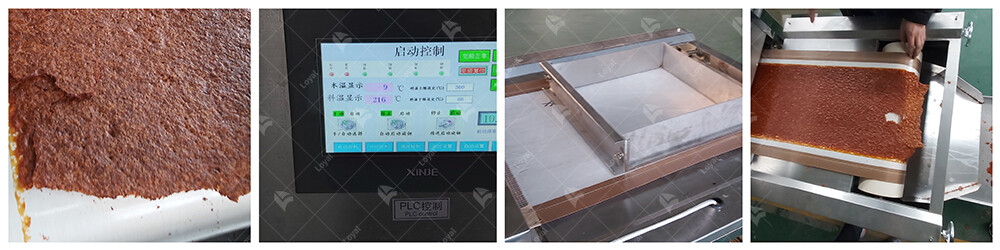

In industrial settings, fennel drying is often performed using specialized equipment known as industrial microwave dryers. These dryers offer an efficient and controlled method for removing moisture from fennel while preserving its flavor, aroma, and nutritional value. The process typically involves several techniques to ensure optimal drying results and product quality.

One common technique used in industrial fennel drying is pre-treatment, where fennel undergoes washing and sorting to remove any impurities or foreign particles. This step helps ensure uniform drying and prevents contamination during the drying process. After pre-treatment, the fennel is evenly spread out on trays or conveyor belts inside the microwave dryer chamber.

Once loaded into the dryer, the fennel is subjected to microwave radiation, which rapidly heats and evaporates the moisture within the product. Industrial microwave dryers offer precise control over temperature and humidity levels, allowing manufacturers to tailor the drying process to meet specific requirements for moisture content and texture.

To optimize drying efficiency, industrial fennel drying may also involve techniques such as rotation or agitation of the product during drying to ensure uniform exposure to microwave energy. Additionally, some dryers may incorporate features such as variable power settings or multi-stage drying processes to further enhance drying performance and product quality.

Overall, industrial fennel drying techniques aim to achieve fast, efficient, and uniform drying results while preserving the natural characteristics of the fennel. By utilizing advanced Fennel Drying Food Microwave Dryer technology and implementing appropriate drying techniques, manufacturers can produce high-quality dried fennel products for various culinary and commercial applications.

Advantages of Industrial Microwave Dryers for Fennel Processing

Advantages | Explanation |

Rapid Drying | Industrial microwave dryers facilitate rapid drying of fennel, significantly reducing processing time compared to traditional drying methods. |

Uniform Heating | The microwave technology ensures uniform heating throughout the fennel, preventing uneven drying and maintaining product quality. |

Preservation of Nutrients | Unlike conventional drying methods, industrial microwave dryers preserve the nutritional value of fennel, including vitamins and minerals. |

Energy Efficiency | Industrial microwave dryers are energy-efficient, utilizing electromagnetic waves to heat the fennel directly, minimizing energy wastage. |

Design Features of Industrial Microwave Dryers

Design Features | Description |

Stainless Steel Construction | Industrial microwave dryers are typically constructed with stainless steel, ensuring durability, hygiene, and resistance to corrosion. |

Conveyor Belt System | These dryers often feature a conveyor belt system for continuous processing, allowing for efficient and automated fennel drying operations. |

Variable Power and Frequency Control | Advanced models offer variable power and frequency control, enabling operators to adjust drying parameters for different fennel products. |

Temperature and Moisture Sensors | Integrated sensors monitor temperature and moisture levels, ensuring precise control over the drying process and consistent product quality. |

Operating Procedures for Fennel Drying with Industrial Microwave Dryers

1. Preparation: Before loading the fennel onto the conveyor belt, ensure that it is cleaned and trimmed to remove any debris or impurities.

2. Loading: Evenly distribute the prepared fennel onto the conveyor belt of the industrial microwave dryer, ensuring that there is sufficient spacing between the pieces for uniform drying.

3. Setting Parameters: Set the desired drying parameters such as power, frequency, temperature, and time based on the specific requirements of the fennel product.

4. Monitoring: Throughout the drying process, monitor the temperature and moisture levels using the integrated sensors, making any necessary adjustments to ensure optimal drying conditions.

5. Unloading: Once the drying cycle is complete, carefully remove the dried fennel from the conveyor belt and transfer it to packaging or storage containers for further processing or distribution.

6. Cleaning and Maintenance: After each use, clean the industrial microwave dryer thoroughly to remove any residue or buildup, and perform routine maintenance to ensure optimal performance and longevity of the equipment.

Efficiency and Cost-effectiveness of Microwave Drying Technology

Fennel Drying Food Microwave Dryer technology offers remarkable efficiency and cost-effectiveness compared to traditional drying methods. Microwave drying utilizes electromagnetic waves to generate heat directly within the material being dried, resulting in rapid and uniform drying. This direct heating mechanism significantly reduces drying time compared to conventional methods, leading to higher throughput and increased productivity in food processing operations. Additionally, industrial microwave dryers are highly energy-efficient, as they only heat the moisture within the product, minimizing heat loss to the surrounding environment. This energy-efficient approach translates to lower operating costs and reduced energy consumption, making microwave drying an economically viable option for food manufacturers.

Moreover, industrial microwave dryers are known for their versatility and flexibility in handling a wide range of food products, including fennel. These dryers can accommodate various product sizes and shapes without the need for extensive reconfiguration, allowing for seamless integration into existing production lines. This versatility further enhances efficiency by minimizing downtime and optimizing production schedules. Additionally, industrial microwave dryers require minimal manual intervention during operation, reducing labor costs and improving overall process efficiency.

In terms of cost-effectiveness, the initial investment in Fennel Drying Food Microwave Dryer technology may be higher than traditional drying equipment. However, the long-term benefits outweigh the upfront costs. The rapid drying capabilities of microwave technology result in shorter processing times, leading to increased throughput and higher product yields. Additionally, the energy-efficient nature of microwave drying reduces utility costs over time, resulting in significant savings in operational expenses. When considering the overall lifecycle costs and benefits, industrial microwave dryers prove to be a cost-effective solution for food processing operations, including fennel drying.

Safety Protocols in Operating Industrial Microwave Dryers

Safety is paramount when operating industrial microwave dryers to ensure the well-being of personnel and the integrity of the food products being processed, including fennel. One fundamental safety protocol is proper training for personnel involved in operating and maintaining the equipment. Operators should receive comprehensive training on the safe operation of industrial microwave dryers, including understanding the equipment's controls, emergency procedures, and potential hazards associated with microwave radiation.

Furthermore, industrial microwave dryers should be equipped with built-in safety features to mitigate risks during operation. These features may include interlocks and sensors that automatically shut off the equipment if any abnormalities are detected, such as overheating or door malfunctions. Regular maintenance and inspection of industrial microwave dryers are essential to ensure that safety systems are functioning correctly and to address any potential issues promptly.

Another critical aspect of safety protocols is the proper handling and loading of food products into the microwave dryer. Personnel should follow established procedures for loading and unloading products to minimize the risk of accidents or injuries. Additionally, food products should be inspected for any foreign objects or contaminants before entering the dryer to prevent contamination and ensure product quality and safety.

It is also essential to implement proper personal protective equipment (PPE) protocols for personnel working in proximity to industrial microwave dryers. This may include wearing protective clothing, gloves, and eye protection to prevent exposure to microwave radiation and other potential hazards.

By adhering to strict safety protocols and procedures, food manufacturers can ensure the safe and efficient operation of industrial microwave dryers for fennel drying, promoting worker safety and product integrity.

Applications and Industries Utilizing Fennel Drying Industrial Microwave Dryers

Industrial microwave dryers have found widespread applications across various industries for drying fennel and other food products. One prominent industry that utilizes fennel drying industrial microwave dryers is the food processing sector. Fennel is a versatile ingredient used in a variety of food products, including seasonings, condiments, and herbal teas. Industrial microwave dryers enable food manufacturers to efficiently dry fennel while preserving its flavor, aroma, and nutritional value, resulting in high-quality products for consumers.

Moreover, the pharmaceutical industry also benefits from the use of fennel drying industrial microwave dryers. Fennel extracts are commonly used in herbal medicine and pharmaceutical formulations for their therapeutic properties. Industrial microwave dryers allow pharmaceutical manufacturers to precisely control the drying process, ensuring the consistency and potency of fennel extracts for use in medications, supplements, and herbal remedies.

Additionally, the cosmetics and personal care industry utilize fennel drying industrial microwave dryers in the production of botanical extracts and essential oils. Fennel oil is valued for its aromatic properties and is used in skincare products, perfumes, and aromatherapy blends. Fennel Drying Food Microwave Dryer technology enables manufacturers to efficiently extract and dry fennel oil while preserving its fragrance and therapeutic benefits, meeting the demand for natural and high-quality ingredients in cosmetic formulations.

In conclusion, industrial microwave dryers play a vital role in various industries, including food processing, pharmaceuticals, cosmetics, and agriculture, by enabling efficient and high-quality drying of fennel and other food products. Their versatility, precision, and efficiency make them indispensable tools for businesses seeking to enhance their product offerings and meet the demands of today's market.

References

The following are five authoritative foreign literature websites in the field of industrial microwaves:

1. IEEE Xplore Digital Library

Website: [https://ieeexplore.ieee.org/]

2.ScienceDirect

Website: [https://www.sciencedirect.com/]

3. SpringerLink

Website: [https://link.springer.com/]

4. Wiley Online Library

Website: [https://onlinelibrary.wiley.com/]

5. PubMed

Website: [https://pubmed.ncbi.nlm.nih.gov/]

Telephone :+86-531-55583139

Telephone :+86-531-55583139 WhatsApp :+86 13256674591

WhatsApp :+86 13256674591 Email :

Email :