The Ultimate White Pepper Powder Microwave Sterilizer Machine Guide to 2024

Introduction

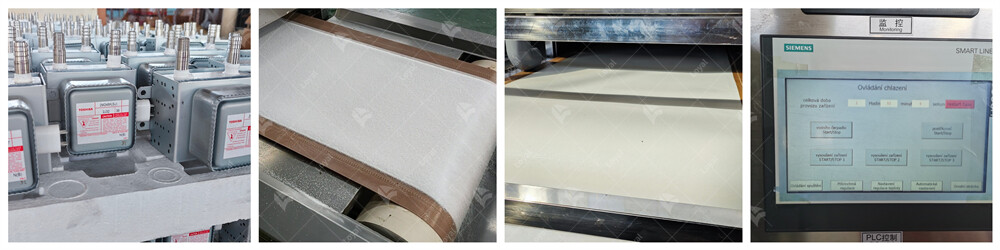

Microwave drying sterilizer machines are cutting-edge equipment used in various industries, particularly in the food sector, to ensure the sterility and dryness of products. These machines utilize microwave energy to generate heat, effectively killing microorganisms and pathogens without compromising the quality of the product. The White Pepper Powder Microwave Sterilizer Machine is an excellent example of how this technology is applied specifically for spices, ensuring they remain safe for consumption while retaining their flavor and nutritional value. Unlike traditional sterilization methods, microwave sterilization is faster, more energy-efficient, and can be tailored to specific requirements, making it a versatile choice for food manufacturers.

The White Pepper Powder Microwave Sterilizer Machine operates by emitting microwaves that penetrate the product, causing water molecules to vibrate and generate heat from within. This internal heating is uniform and quick, significantly reducing processing time compared to conventional methods. Moreover, the ability to precisely control the temperature and duration of the process helps in maintaining the integrity of the white pepper powder, preventing it from losing its essential oils and aromatic properties. The use of such advanced technology not only enhances the safety of food products but also supports the growing demand for high-quality, minimally processed spices in the market.

How Microwave Drying Sterilizer Machines Work

Microwave drying sterilizer machines, particularly the White Pepper Powder Microwave Sterilizer Machine, utilize advanced microwave technology to achieve both drying and sterilization simultaneously. The process begins with the application of microwave energy, which penetrates the white pepper powder, causing the water molecules within to rapidly heat up and evaporate. This rapid evaporation leads to effective drying of the powder.

The key to the sterilization process lies in the ability of microwave energy to generate heat uniformly throughout the white pepper powder. As the microwaves agitate the water molecules, the resulting friction produces heat, raising the temperature to levels sufficient to kill bacteria, mold, and other microorganisms. This ensures that the white pepper powder is not only dried but also thoroughly sterilized.

Another crucial aspect of the White Pepper Powder Microwave Sterilizer Machine is its ability to operate at lower temperatures compared to traditional sterilization methods. By doing so, it preserves the essential oils and flavors of the white pepper powder, maintaining its quality and potency. The combination of efficient drying and thorough sterilization makes these machines indispensable in the food processing industry.

The process control in these machines is highly precise, with advanced sensors and control systems ensuring consistent and repeatable results. Operators can adjust the microwave power, exposure time, and other parameters to optimize the drying and sterilization process for different batches of white pepper powder. This flexibility is one of the key advantages of using microwave drying sterilizer machines.

Advantages of Microwave Drying Sterilizers

Microwave drying sterilizers, such as the White Pepper Powder Microwave Sterilizer Machine, offer numerous advantages over traditional drying and sterilization methods. One of the primary benefits is the significant reduction in processing time. Microwave energy penetrates the white pepper powder quickly and uniformly, resulting in faster drying and sterilization compared to conventional heat methods.

Another advantage is the energy efficiency of microwave drying sterilizers. These machines utilize direct microwave energy to heat the product, minimizing energy loss. This direct application of energy means that less overall energy is required to achieve the desired drying and sterilization, making the process more cost-effective and environmentally friendly.

The White Pepper Powder Microwave Sterilizer Machine also ensures superior product quality. Traditional high-temperature sterilization methods can degrade the quality of white pepper powder by altering its flavor, color, and nutritional content. In contrast, microwave sterilization operates at lower temperatures, preserving the intrinsic properties of the white pepper powder, such as its flavor and nutritional value, while still achieving effective sterilization.

Moreover, microwave drying sterilizers are highly versatile and can be used for a wide range of food products beyond white pepper powder. The flexibility in adjusting processing parameters allows these machines to handle different types of powders, spices, and other food items with varying moisture content and microbial load. This adaptability makes microwave drying sterilizers a valuable asset in the food processing industry, offering consistent, high-quality results across diverse applications.

Selecting the Right Microwave Sterilizer for Your Needs

When it comes to selecting the appropriate microwave sterilizer for your industrial food processing needs, comparing the offerings of leading companies like LOYAL and Coperion can provide valuable insights. Below is a simple table highlighting the key features and specifications of both companies' machines:

| Criteria | LOYAL Microwave Sterilizer | Coperion Microwave Sterilizer |

| Sterilization Capacity | High capacity models available for bulk processing | Suitable for smaller scale operations |

| Technology | Utilizes advanced microwave sterilization technology | Incorporates innovative sterilization techniques |

| Efficiency | Rapid sterilization process, reducing production time | Effective sterilization with minimal energy consumption |

| Customization Options | Offers customizable features to meet specific industry requirements | Limited customization options |

| Maintenance | Easy to maintain with user-friendly interface | Requires regular maintenance checks |

| Cost | Competitive pricing with flexible financing options | Higher initial investment but cost-effective in the long run |

| Customer Support | Dedicated customer support team available 24/7 | Comprehensive technical assistance and training programs |

Based on this comparison, if you're operating on a larger scale and prioritize efficiency and customization, the LOYAL microwave sterilizer might be the ideal choice. However, if you're looking for a more cost-effective solution suitable for smaller operations, the Coperion microwave sterilizer could be a better fit. Ultimately, the decision should align with your specific production requirements and budget constraints.

Industrial Applications of Microwave Sterilizers

Microwave sterilizers have revolutionized various industries with their efficient and effective sterilization capabilities. From food processing to pharmaceutical manufacturing, these machines play a crucial role in ensuring product safety and quality. Below is an overview of some key industrial applications of microwave sterilizers:

| Industry | Application |

| Food Processing | Microwave sterilizers are extensively used in the food industry for sterilizing a wide range of products, including spices, herbs, dried fruits, and ready-to-eat meals. The technology efficiently eliminates harmful pathogens such as bacteria and molds, extending the shelf life of food products while preserving their nutritional value. |

| Pharmaceutical | In pharmaceutical manufacturing, microwave sterilizers are utilized for sterilizing equipment, packaging materials, and certain medications. The rapid and uniform heating provided by microwave technology ensures the destruction of bacteria, viruses, and other microorganisms, meeting stringent regulatory requirements for product safety and quality. |

| Medical | Microwave sterilizers find applications in medical facilities for sterilizing surgical instruments, medical devices, and laboratory equipment. Their quick turnaround time and efficacy in killing a wide range of pathogens make them indispensable in healthcare settings, where infection control is paramount. |

| Agriculture | Microwave sterilizers are increasingly being used in agriculture for seed disinfection and pest control. By subjecting seeds to controlled microwave radiation, pathogens and pests present on the seed surface can be effectively eradicated, enhancing germination rates and crop yields. |

| Environmental | Microwave sterilization technology is also employed in environmental remediation efforts, particularly in wastewater treatment and soil decontamination. The ability of microwaves to penetrate and heat organic matter can aid in the destruction of harmful pathogens and pollutants, contributing to environmental sustainability. |

These industrial applications underscore the versatility and effectiveness of microwave sterilizers in ensuring product safety, quality, and regulatory compliance across diverse sectors.

Efficiency and Energy Consumption of Microwave Machines

Efficiency and energy consumption are critical considerations in the operation of microwave sterilizer machines, as they directly impact productivity, operating costs, and environmental sustainability.

Microwave sterilizers are renowned for their rapid heating capabilities, which significantly reduce processing time compared to traditional sterilization methods. This efficiency translates to higher throughput and increased productivity in industrial settings, allowing manufacturers to meet demand while minimizing production time and costs.

Moreover, the precise and uniform heating provided by microwave technology ensures consistent sterilization results, eliminating the need for prolonged exposure to high temperatures or chemicals. This not only enhances product quality but also reduces energy consumption by optimizing the sterilization process.

In terms of energy consumption, microwave sterilizers are generally more energy-efficient than conventional thermal sterilization methods. The focused application of microwave energy targets the desired product, minimizing heat loss and reducing overall energy requirements. Additionally, advanced control systems allow for precise adjustment of power levels and heating times, further optimizing energy usage while maintaining sterilization efficacy.

Furthermore, the modular design of many microwave sterilizer systems enables efficient use of space and resources, facilitating streamlined production workflows and minimizing energy wastage.

Overall, the efficiency and energy consumption of microwave sterilizer machines make them a sustainable and cost-effective solution for various industrial applications, contributing to enhanced productivity, product quality, and environmental stewardship.

Troubleshooting Common Issues in Microwave Machines

1. Understanding Common Problems: Microwave machines, including sterilizers, may encounter several issues during operation. These problems can disrupt production and affect product quality.

2. Power Supply Interruptions: One common issue is power supply interruptions, which can lead to sudden shutdowns or fluctuations in microwave sterilizers. This can be caused by electrical faults, grid failures, or issues with the machine's power source.

3. Uneven Heating: Another frequent problem is uneven heating within the sterilization chamber. This can result in some areas being overcooked while others remain underprocessed. Uneven heating may occur due to faulty microwave emitters, improper placement of products, or irregularities in the chamber's design.

4. Equipment Malfunctions: Equipment malfunctions such as broken components, faulty sensors, or malfunctioning control panels can also occur. These issues can disrupt the sterilization process and require immediate attention from maintenance personnel.

Innovations in Microwave Sterilization Technology

1. Integration of Advanced Sensors: One of the most significant innovations in microwave sterilization technology is the integration of advanced sensors. These sensors continuously monitor temperature, humidity, and other relevant parameters within the sterilization chamber, allowing for real-time adjustments to optimize the sterilization process.

2. Adaptive Control Systems: Another innovative approach is the development of adaptive control systems that can dynamically adjust microwave power, frequency, and other parameters based on the specific characteristics of the product being sterilized. This ensures consistent and precise sterilization while minimizing energy consumption and processing time.

3. Enhanced Safety Features: Recent advancements in microwave sterilization technology have focused on enhancing safety features to prevent accidents and ensure operator protection. This includes improved interlocking mechanisms, emergency stop systems, and automated shutdown procedures in case of anomalies or malfunctions.

4. Integration with Industry 4.0: With the rise of Industry 4.0 technologies, microwave sterilization machines are increasingly being integrated into networked production systems. This allows for remote monitoring, predictive maintenance, and data-driven process optimization, leading to greater efficiency, reliability, and scalability in food production facilities.

User Training for Microwave Drying Sterilizer Machines

1. Importance of Proper Training: White Pepper Powder Microwave Sterilizer Machine requires specialized knowledge to operate efficiently and safely. Training users on its operation is crucial to ensure optimal performance and prevent accidents.

2. Comprehensive Training Program: A comprehensive training program should cover various aspects, including machine setup, operation procedures, safety protocols, maintenance routines, and troubleshooting techniques. Users should undergo both theoretical and practical training sessions to gain a thorough understanding of the equipment.

3. Hands-On Practice: Hands-on practice is essential for users to familiarize themselves with the White Pepper Powder Microwave Sterilizer Machine. Training sessions should include simulated scenarios where users can practice loading and unloading products, adjusting settings, and monitoring the sterilization process under supervision.

4. Ongoing Support and Refresher Courses: Continuous support and refresher courses should be provided to users to keep their skills up-to-date and address any new developments or upgrades in the equipment. Regular training sessions also reinforce safety practices and ensure compliance with industry standards.

Future Trends in Microwave Drying Technology

1. Advancements in Efficiency: Future microwave drying technology is expected to focus on enhancing efficiency by optimizing energy consumption and reducing processing time. Innovations in microwave generator design and control systems will contribute to more precise and uniform heating, leading to higher throughput and lower operating costs.

2. Integration of Automation: Automation will play a significant role in the future of microwave drying technology, enabling seamless integration with other processes in food production lines. Automated systems equipped with sensors and AI algorithms will enable real-time monitoring and adjustment of drying parameters for optimal results.

3. Development of Smart Drying Solutions: The emergence of smart technologies will revolutionize microwave drying processes, allowing for remote monitoring and control via mobile devices or cloud-based platforms. Smart sensors embedded in the equipment will provide valuable data insights, allowing operators to optimize drying conditions and improve product quality.

Focus on Sustainability: Future trends in microwave drying technology will also prioritize sustainability, with efforts to minimize environmental impact and reduce resource consumption. Eco-friendly materials, recycling systems, and renewable energy sources will be incorporated into equipment design to align with global sustainability goals.

References

1. Website: Food Processing Technology

URL: https://www.foodprocessing-technology.com/

2. Website: Food Engineering Magazine

URL: https://www.foodengineeringmag.com/

3. Website: Food Manufacturing Magazine

URL: https://www.foodmanufacturing.com/

4. Website: Packaging Digest

URL: https://www.packagingdigest.com/

5. Website: Food Quality & Safety Magazine

Telephone :+86-531-55583139

Telephone :+86-531-55583139 WhatsApp :+86 13256674591

WhatsApp :+86 13256674591 Email :

Email :