The Ultimate Sunflower Seed Microwave Dryer Machine Guide to 2024

Introduction to Sunflower Seed Microwave Dryer Machines

Sunflower seed microwave dryer machines represent a significant advancement in the food processing industry, specifically tailored for drying sunflower seeds efficiently and effectively. These machines utilize microwave technology to ensure rapid drying, reducing processing time while maintaining the nutritional integrity of the seeds. The increasing demand for healthy snacks and oil-rich seeds has driven the adoption of advanced drying technologies, with sunflower seed microwave dryer machines at the forefront.

Sunflower seed microwave dryer machines offer numerous benefits, including enhanced drying uniformity, energy efficiency, and preservation of flavor and nutrients. Traditional drying methods often result in uneven drying and potential loss of quality due to prolonged exposure to heat. In contrast, microwave drying provides a controlled environment that minimizes these risks, making it an ideal choice for large-scale industrial operations. Moreover, these machines are designed to handle large volumes of sunflower seeds, making them suitable for commercial use.

The adoption of sunflower seed microwave dryer machines also aligns with sustainability goals. These machines consume less energy compared to conventional drying methods, leading to lower operational costs and reduced carbon footprint. As environmental concerns continue to influence industrial practices, the shift towards energy-efficient technologies like microwave drying is becoming increasingly important.

In summary, sunflower seed microwave dryer machines are a crucial innovation in the food processing industry, offering efficient, uniform, and sustainable drying solutions. Their ability to maintain product quality while reducing processing times and energy consumption makes them an essential tool for modern food processing facilities.

How Sunflower Seed Microwave Dryer Machines Work

Sunflower seed microwave dryer machines operate on the principle of dielectric heating, where microwaves generate heat by causing water molecules within the seeds to vibrate. This process is fundamentally different from conventional heating methods, which rely on external heat sources. The microwaves penetrate the seeds, heating them from the inside out, leading to rapid and uniform drying.

The core component of a sunflower seed microwave dryer machine is the microwave generator, which produces electromagnetic waves at specific frequencies. These microwaves are directed into the drying chamber, where the sunflower seeds are placed. As the microwaves interact with the water molecules in the seeds, the energy is converted into heat, causing the water to evaporate. This method ensures that the seeds are dried evenly, reducing the risk of over-drying or scorching.

Another critical aspect of these machines is their control system, which allows precise regulation of microwave power, drying time, and temperature. Operators can adjust these parameters to optimize the drying process based on the specific characteristics of the sunflower seeds, such as moisture content and desired final quality. Advanced models may also include sensors that monitor the drying process in real-time, providing feedback to adjust the settings automatically for optimal results.

Moreover, sunflower seed microwave dryer machines often incorporate features such as conveyor belts or rotating drums to ensure continuous and consistent drying. These mechanisms allow for the even distribution of seeds within the drying chamber, further enhancing the uniformity of the drying process. The integration of these technologies results in a highly efficient drying system that maximizes throughput and product quality.

Types of Sunflower Seed Microwave Dryer Machines

There are various types of sunflower seed microwave dryer machines available in the market, each designed to meet specific industrial needs. These machines can be broadly categorized based on their capacity, design, and specific functionalities. The following table provides a detailed comparison of the main types:

Type | Description | Capacity | Key Features |

Batch Microwave Dryer Machine | Designed for small to medium-scale operations. Seeds are dried in batches. | Up to 500 kg/batch | High precision, easy to operate, cost-effective |

Continuous Microwave Dryer Machine | Ideal for large-scale operations. Provides continuous drying of seeds. | Up to 2000 kg/hour | High throughput, consistent drying, automated |

Vacuum Microwave Dryer Machine | Uses vacuum to enhance drying efficiency and preserve seed quality. | Up to 1000 kg/batch | Low temperature drying, high efficiency, gentle |

Hybrid Microwave Dryer Machine | Combines microwave with hot air or infrared for enhanced drying performance. | Up to 1500 kg/hour | Multifunctional, efficient energy use, versatile |

Each type of sunflower seed microwave dryer machine offers unique advantages tailored to different production needs, from small artisanal batches to large-scale industrial processing.

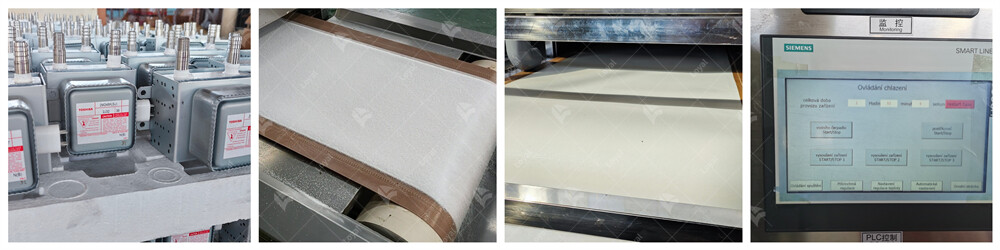

Key Components and Features of Sunflower Seed Microwave Dryer Machines

Sunflower seed microwave dryer machines are complex pieces of industrial equipment designed to provide efficient and consistent drying of sunflower seeds. Understanding the key components and features of these machines is crucial for optimizing their use in food processing industries.

1. Microwave Generator:

The core component of the sunflower seed microwave dryer machine is the microwave generator, which produces the microwave energy used to heat and dry the seeds. This component ensures rapid and uniform heating, reducing drying time significantly compared to conventional methods.

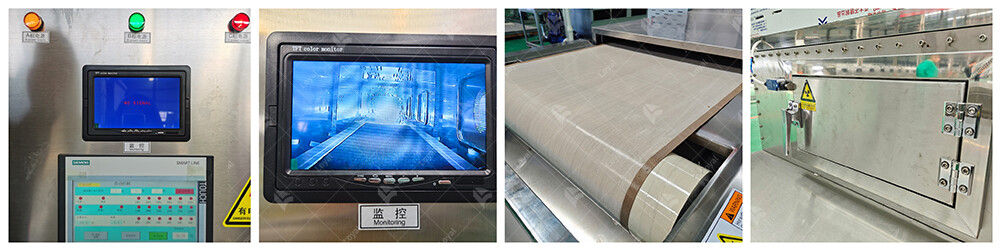

2. Control System:

Modern sunflower seed microwave dryer machines are equipped with advanced control systems that allow precise regulation of drying parameters such as temperature, microwave power, and drying time. These systems often include touch-screen interfaces and programmable settings to facilitate easy operation and customization.

3. Conveyor System:

For continuous microwave dryer machines, the conveyor system is a critical component. It transports sunflower seeds through the drying chamber at a controlled speed, ensuring even exposure to microwave energy and consistent drying. The conveyor material must be microwave-transparent to avoid interference with the drying process.

4. Drying Chamber:

The drying chamber is where the actual drying process occurs. It is designed to maximize the exposure of sunflower seeds to microwave energy while maintaining an optimal drying environment. Features such as adjustable air vents and humidity controls are often included to enhance drying efficiency and product quality.

In conclusion, the sunflower seed microwave dryer machine incorporates several key components and features that work together to provide efficient and effective drying. By understanding these elements, operators can optimize the use of these machines to achieve high-quality, uniformly dried sunflower seeds.

Applications of Sunflower Seed Microwave Dryer Machines in Food Processing

Sunflower seed microwave dryer machines are integral to the food processing industry, offering several advantages over traditional drying methods. These machines use microwave energy to heat and dry sunflower seeds efficiently, preserving their nutritional content and quality.

1. Roasting and Drying:

One of the primary applications of sunflower seed microwave dryer machines is in the roasting and drying process. These machines ensure uniform heating, which enhances the flavor and texture of the sunflower seeds while maintaining their nutritional value. The rapid drying process reduces the risk of microbial contamination, making the seeds safer for consumption.

2. Preservation:

Sunflower seed microwave dryer machines are also used for preservation purposes. The drying process effectively reduces the moisture content of sunflower seeds, inhibiting the growth of mold and bacteria. This extends the shelf life of the seeds, making them suitable for long-term storage and export.

3. Oil Extraction:

In the oil extraction industry, sunflower seed microwave dryer machines play a crucial role. Drying the seeds before oil extraction increases the efficiency of the extraction process. The low moisture content of the dried seeds results in higher oil yields and better quality oil, benefiting manufacturers and consumers alike.

4. Snack Production:

The production of sunflower seed snacks benefits significantly from the use of microwave drying technology. Sunflower seed microwave dryer machines produce evenly dried seeds that are crispy and have a pleasant taste. This consistency in quality is essential for snack producers to meet consumer expectations and maintain product standards.

Energy Efficiency and Environmental Impact of Sunflower Seed Microwave Dryer Machines

Sunflower seed microwave dryer machines are designed to be energy-efficient and environmentally friendly. Here is a comparison table highlighting the key aspects of their energy efficiency and environmental impact:

Aspect | Sunflower Seed Microwave Dryer Machine | Traditional Drying Methods |

Energy Consumption | Lower energy consumption due to targeted microwave heating | Higher energy consumption due to prolonged drying periods |

Heating Efficiency | High efficiency with uniform heating and reduced heat loss | Lower efficiency with uneven heating and significant heat loss |

Processing Time | Shorter processing time, leading to energy savings | Longer processing time, resulting in higher energy usage |

Carbon Footprint | Reduced carbon footprint due to efficient energy use | Higher carbon footprint due to extended operation and higher energy demand |

Environmental Impact | Minimal environmental impact with lower emissions | Greater environmental impact with higher emissions |

Water Usage | No water usage, reducing overall resource consumption | Often requires water for cooling, increasing resource consumption |

Product Quality | Maintains high nutritional value and quality due to gentle drying process | Potential degradation of nutritional value and quality due to extended drying |

In conclusion, sunflower seed microwave dryer machines offer significant advantages in terms of energy efficiency and environmental impact. They consume less energy, reduce processing times, and have a lower carbon footprint compared to traditional drying methods. These machines not only benefit manufacturers by lowering operational costs but also contribute to sustainability efforts by minimizing environmental impact.

Installation and Setup Guide for Sunflower Seed Microwave Dryer Machines

Installing and setting up a sunflower seed microwave dryer machine correctly is crucial for its efficient operation. Here's a comprehensive guide to help you with the process:

1. Location Selection:

Choose a suitable location for installing the sunflower seed microwave dryer machine. Ensure that the area is well-ventilated and free from obstructions. It should also have access to power sources and adequate space for maintenance activities.

2. Machine Assembly:

Follow the manufacturer's instructions for assembling the sunflower seed microwave dryer machine. This may involve attaching various components such as the microwave chamber, conveyor belts, control panel, and ventilation system. Ensure that all components are securely attached and aligned correctly.

3. Electrical Connection:

Connect the sunflower seed microwave dryer machine to the appropriate power source as per the manufacturer's specifications. Use recommended cables and connectors to prevent electrical hazards. Test the electrical connections to ensure they are secure and functioning correctly.

4. Ventilation System Installation:

Install the ventilation system of the sunflower seed microwave dryer machine according to the manufacturer's guidelines. Proper ventilation is essential for dissipating heat generated during the drying process and maintaining optimal operating conditions.

Safety Precautions for Sunflower Seed Microwave Dryer Machines

Ensuring safety while operating sunflower seed microwave dryer machines is paramount to protect both personnel and the equipment itself. Here are some essential safety precautions to follow:

1. Training and Education:

Provide comprehensive training to operators on the safe operation of sunflower seed microwave dryer machines. This includes instruction on proper machine usage, emergency procedures, and hazard awareness. Regular refresher training should be conducted to reinforce safety protocols.

2. Personal Protective Equipment (PPE):

Require operators to wear appropriate PPE, such as safety gloves, goggles, and protective clothing, when working with sunflower seed microwave dryer machines. This helps minimize the risk of injury from exposure to high temperatures, moving parts, and microwave radiation.

3. Machine Inspection and Maintenance:

Implement a regular inspection and maintenance schedule for sunflower seed microwave dryer machines to identify and address potential safety hazards promptly. This includes checking for loose components, worn-out parts, and signs of overheating.

4. Emergency Shutdown Procedures:

Establish clear emergency shutdown procedures in case of equipment malfunction, overheating, or other emergencies. Operators should be trained to execute these procedures swiftly to prevent accidents and minimize damage to personnel and the machine.

Future Trends in Sunflower Seed Microwave Dryer Machines

Sunflower seed microwave dryer machines are continuously evolving to meet the growing demands of the food processing industry. Let's explore some of the future trends anticipated in this field:

1. Enhanced Efficiency and Speed:

Future sunflower seed microwave dryer machines are expected to be more efficient and faster in drying processes. Advancements in technology will lead to improved heating mechanisms and better control systems, resulting in reduced drying times and increased productivity.

2. Integration of Smart Technology:

The incorporation of smart technology into sunflower seed microwave dryer machines is on the horizon. This includes the use of IoT (Internet of Things) devices and sensors to monitor and control drying parameters in real-time, allowing for remote operation and optimization of drying processes.

3. Energy Conservation and Sustainability:

Future trends in sunflower seed microwave dryer machines will focus on energy conservation and sustainability. Manufacturers will develop machines that utilize renewable energy sources and incorporate energy-saving features such as heat recovery systems and optimized insulation to minimize environmental impact.

4. Customization and Flexibility:

There will be a growing demand for sunflower seed microwave dryer machines that offer greater customization and flexibility to accommodate diverse product requirements. Future machines will be equipped with modular designs and adjustable settings to cater to different drying needs and processing conditions.

In conclusion, the future of sunflower seed microwave dryer machines is promising, with advancements in efficiency, smart technology integration, energy conservation, and customization expected to drive innovation in the food processing industry.

References

1. Website: Food Processing Technology

URL: https://www.foodprocessing-technology.com/

2. Website: Food Engineering Magazine

URL: https://www.foodengineeringmag.com/

3. Website: Food Manufacturing Magazine

URL: https://www.foodmanufacturing.com/

4. Website: Packaging Digest

URL: https://www.packagingdigest.com/

5. Website: Food Quality & Safety Magazine

Telephone :+86-531-55583139

Telephone :+86-531-55583139 WhatsApp :+86 13256674591

WhatsApp :+86 13256674591 Email :

Email :