The Ultimate Microwave Snack Shrimp Chip Puffing Machine Guide to 2024

Introduction to Microwave Snack Shrimp Chip Puffing Machines

Microwave snack shrimp chip puffing machines are advanced industrial equipment designed to streamline the production process of various snack products. These machines integrate microwave technology with precision engineering to produce high-quality shrimp chips and other puffed snacks efficiently.

In recent years, the demand for convenient and flavorful snacks has surged, driving the need for innovative production solutions. Microwave snack shrimp chip puffing machines have emerged as a cornerstone in meeting this demand by offering fast and reliable manufacturing capabilities.

Evolution of Microwave Snack Production Technology

The evolution of microwave snack production technology has been marked by significant advancements in efficiency, quality, and versatility. Initially, snack production relied heavily on traditional methods, which often lacked consistency and scalability. However, with the introduction of microwave technology, the landscape of snack manufacturing underwent a transformative shift.

Microwave snack production technology has evolved from rudimentary setups to sophisticated systems that incorporate precise control mechanisms and automation features. These advancements have revolutionized the way snacks are produced, allowing manufacturers to achieve higher levels of productivity and product quality.

As consumer preferences continue to evolve, so too does microwave snack production technology. Manufacturers are constantly innovating and refining their equipment to meet the growing demand for healthier, more flavorful snacks. Today, microwave snack shrimp chip puffing machines represent the pinnacle of snack production technology, offering unmatched efficiency, reliability, and product consistency.

Key Components and Functions of Shrimp Chip Puffing Machines

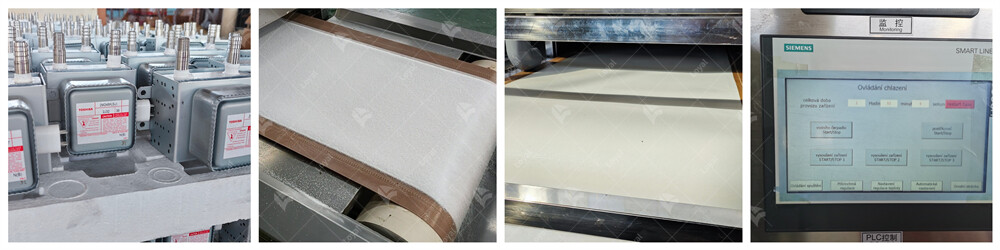

Microwave snack shrimp chip puffing machines are intricate systems comprising various components, each playing a crucial role in the snack production process. Let's delve into the key components and their functions.

First and foremost, the microwave generator stands as the heart of the machine, responsible for producing the electromagnetic waves necessary for puffing the snacks. These waves interact with the moisture and starch content in the raw ingredients, causing them to expand and form the desired texture.

Accompanying the microwave generator is the conveyor belt system, which facilitates the movement of raw materials through the machine. This system ensures a continuous flow of ingredients, optimizing production efficiency. Additionally, adjustable speed settings allow for precise control over the puffing process, ensuring consistent snack quality.

Next, we have the chamber or cavity, where the magic truly happens. This enclosed space provides the ideal environment for the puffing process to occur. Within the chamber, the raw ingredients are exposed to the microwave energy, leading to rapid expansion and transformation into delicious, airy snacks.

Complementing these components is the control panel, serving as the brains of the operation. Here, operators can monitor and adjust various parameters such as temperature, moisture levels, and microwave power to achieve the desired snack characteristics. Additionally, modern machines may feature intuitive interfaces and programmable settings for enhanced user experience and efficiency.

Understanding the Puffing Process: From Raw Ingredients to Finished Snacks

The puffing process in microwave snack shrimp chip puffing machines is a complex yet fascinating journey that begins with carefully selected raw ingredients and culminates in delectable finished snacks.

It all starts with the preparation of the raw materials, which typically include shrimp paste, starches, seasonings, and other flavorings. These ingredients are mixed to achieve the desired consistency and flavor profile, ensuring uniformity in the final product.

Once prepared, the raw materials are fed into the microwave snack shrimp chip puffing machine, where they undergo a series of transformations. As the ingredients pass through the microwave chamber, they are exposed to intense electromagnetic waves, causing them to heat up rapidly.

As the temperature rises, the moisture within the ingredients begins to vaporize, creating pressure within the food matrix. Simultaneously, the starches gelatinize, forming a structure that traps the expanding gases. This combination of pressure and structural changes leads to the characteristic puffing and expansion of the snacks.

Throughout this process, precise control over factors such as temperature, moisture content, and microwave power is essential to achieving consistent results. By fine-tuning these parameters, manufacturers can produce snacks with the perfect texture, flavor, and appearance, satisfying consumers' cravings for crispy, crunchy goodness.

Advantages of Microwave Technology in Snack Production

Microwave technology has revolutionized the snack production industry, offering numerous advantages over traditional methods. Let's delve into the benefits of utilizing microwave technology in snack production.

1. Enhanced Efficiency: Microwave snack production machines boast rapid processing times, significantly reducing production cycles. Unlike conventional methods that rely on lengthy baking or frying processes, microwave technology allows for quick heating and cooking of snack ingredients. This results in higher production rates and increased output, meeting the demands of a fast-paced market.

2. Preservation of Nutritional Value: Microwave heating is known for its ability to preserve the nutritional integrity of food products. Unlike frying, which may lead to nutrient degradation, microwave technology ensures minimal loss of vitamins, minerals, and other essential nutrients during the production process. This aspect is particularly crucial in snack production, where consumers increasingly prioritize health and wellness.

3. Versatility and Customization: Microwave snack production machines offer unparalleled versatility, allowing manufacturers to produce a wide range of snack varieties with ease. From crispy chips to savory shrimp snacks, microwave technology accommodates various ingredients and recipes, enabling customization to cater to diverse consumer preferences. This flexibility gives manufacturers a competitive edge in meeting evolving market trends and demands.

4. Energy Efficiency: Compared to conventional cooking methods, microwave technology is renowned for its energy efficiency. By directly targeting food molecules with electromagnetic waves, microwave heating minimizes energy wastage associated with heating entire ovens or fryers. This not only reduces production costs but also aligns with sustainability initiatives aimed at minimizing environmental impact.

Quality Control and Safety Measures in Shrimp Chip Puffing Machines

Ensuring quality and safety in shrimp chip puffing machines is paramount to delivering superior products and maintaining consumer trust. Let's explore the essential quality control and safety measures implemented in these machines.

1. Precision Temperature Control: Shrimp chip puffing machines are equipped with advanced temperature control systems to maintain precise cooking temperatures throughout the production process. This ensures consistent product quality and minimizes the risk of undercooked or overcooked snacks, thereby upholding food safety standards.

2. Hygiene and Sanitation Protocols: Strict hygiene and sanitation protocols are essential in shrimp chip puffing machines to prevent contamination and ensure product safety. Machines are designed with easy-to-clean surfaces and removable parts, facilitating thorough cleaning and disinfection between production runs. Regular maintenance schedules and sanitation procedures are followed diligently to uphold hygiene standards.

3. Quality Assurance Testing: Quality assurance testing is conducted at various stages of the production process to monitor product quality and adherence to specifications. This includes sensory evaluation, texture analysis, and microbiological testing to detect any deviations from quality standards. Any non-compliant products are promptly identified and removed from the production line to maintain product integrity.

4..Compliance with Regulatory Standards: Shrimp chip puffing machines adhere to stringent regulatory standards and certifications to ensure compliance with food safety regulations. Manufacturers invest in rigorous testing and certification processes to demonstrate the safety and reliability of their equipment. Additionally, ongoing training and education programs ensure that operators are well-versed in safety protocols and best practices.

Comparing Different Manufacturers of Microwave Snack Shrimp Chip Puffing Machines

When it comes to choosing a microwave snack shrimp chip puffing machine, two prominent manufacturers stand out: LoyAL and Coperion. Both companies offer state-of-the-art machines designed to meet the diverse needs of snack producers. Let's compare the key features and specifications of LoyAL and Coperion machines:

Feature | LoyAL Microwave Snack Shrimp Chip Puffing Machine | Coperion Microwave Snack Shrimp Chip Puffing Machine |

Production Capacity | High | Moderate |

Automation Level | Fully Automated | Semi-Automated |

Customization Options | Extensive | Limited |

Energy Efficiency | High | Moderate |

Quality and Reliability | Excellent | Good |

After-Sales Support | Comprehensive | Standard |

In summary, both LoyAL and Coperion offer reliable microwave snack shrimp chip puffing machines with unique features and advantages. Depending on the specific requirements and budget of a snack production facility, either option can provide efficient and high-quality solutions for producing delicious microwave snacks.

Innovations in Microwave Snack Production: Trends and Future Outlook

As the demand for convenient and tasty snacks continues to rise, the microwave snack production industry is experiencing significant innovations and advancements. One of the key trends shaping the future outlook of microwave snack production is the integration of cutting-edge technology to enhance efficiency and quality.

Automation and robotics have emerged as game-changers in the microwave snack production industry. Manufacturers are increasingly incorporating advanced robotics into their production lines to streamline processes and increase output. These robotic systems can handle various tasks, including ingredient mixing, shaping, and packaging, with precision and speed. By reducing manual labor and human error, automation not only improves efficiency but also ensures consistent product quality.

In response to growing environmental concerns, microwave snack manufacturers are embracing sustainable practices and eco-friendly packaging solutions. From using biodegradable packaging materials to optimizing energy consumption in production processes, companies are prioritizing sustainability throughout their operations. Additionally, innovations such as compostable snack packaging and renewable energy-powered production facilities are gaining traction as consumers increasingly demand eco-conscious snack options.

Another trend driving innovation in microwave snack production is flavor innovation and customization. Consumers today crave unique and exotic flavor experiences, prompting manufacturers to experiment with a diverse range of ingredients and flavor combinations. From spicy sriracha shrimp chips to tangy barbecue puff snacks, the possibilities are endless. Moreover, advancements in flavor encapsulation technology allow manufacturers to create snacks with long-lasting and intense flavor profiles, ensuring maximum consumer satisfaction.

In recent years, there has been a growing emphasis on nutritional enhancement and the incorporation of functional ingredients in microwave snack production. Consumers are increasingly seeking snacks that not only taste great but also offer health benefits. As a result, manufacturers are fortifying their snacks with vitamins, minerals, and other functional ingredients to appeal to health-conscious consumers. From protein-packed shrimp chips to fiber-rich puff snacks, these nutritionally enhanced snacks cater to a wide range of dietary preferences and requirements.

Maintenance and Troubleshooting Tips for Optimal Machine Performance

Microwave snack shrimp chip puffing machines are intricate pieces of equipment that require regular maintenance to ensure optimal performance. Here are some essential maintenance and troubleshooting tips to keep your machine running smoothly.

Regular Cleaning and Inspection: Regularly clean and inspect all components of the microwave snack shrimp chip puffing machine to prevent buildup and damage. Pay particular attention to the microwave chamber, conveyor belts, and heating elements. Any accumulation of food residue or debris can affect the machine's performance and efficiency.

Check for Wear and Tear: Routinely check for signs of wear and tear on critical components such as belts, bearings, and seals. Replace any worn or damaged parts immediately to prevent further damage to the machine and ensure consistent performance. Keeping spare parts on hand can minimize downtime and production disruptions.

Calibration and Adjustment: Periodically calibrate and adjust the machine's settings to maintain optimal performance. This includes adjusting the temperature, pressure, and speed settings to ensure consistent product quality and production efficiency. Regular calibration can also extend the lifespan of the machine and reduce the risk of breakdowns.

Troubleshooting Common Issues: Familiarize yourself with common issues that may arise during operation, such as uneven puffing, product sticking, or conveyor belt jams. Develop a troubleshooting guide with step-by-step instructions for diagnosing and resolving these issues quickly and effectively. Training your staff on troubleshooting procedures can minimize downtime and maximize productivity.

Innovations in Microwave Snack Production: Trends and Future Outlook

In the ever-evolving landscape of snack production, innovations in microwave technology have revolutionized the way snacks are made. Microwave snack production encompasses a wide range of products, including chips, puffs, and even shrimp snacks. These innovations have not only improved efficiency but also enhanced the quality and variety of snacks available to consumers.

One of the most notable advancements in microwave snack production is the development of specialized machines for producing shrimp chips. These machines utilize advanced microwave technology to quickly and efficiently puff raw shrimp chips, resulting in a crispy and flavorful snack. By harnessing the power of microwaves, these machines can achieve consistent results while minimizing energy consumption and production time.

Another key trend in microwave snack production is the integration of smart technology into production equipment. Modern microwave snack shrimp chip puffing machines are equipped with advanced sensors and controls that allow for precise monitoring and adjustment of key parameters such as temperature, humidity, and cooking time. This not only ensures optimal product quality but also improves overall efficiency and reduces waste.

Looking ahead, the future of microwave snack production looks promising. As consumer demand for healthier and more diverse snack options continues to grow, manufacturers are investing in research and development to create innovative new products. This includes exploring alternative ingredients, such as plant-based proteins, as well as experimenting with new flavor profiles and textures. Additionally, advancements in packaging technology are enabling manufacturers to extend the shelf life of microwave snacks without the need for preservatives, further enhancing their appeal to health-conscious consumers.

References

1.Tetra Pak : https://www.tetrapak.com

2.Jinan Kelid Machinery Co., Ltd.: http://www.kldfoodmachine.com

3. GEA : https://www.gea.com

4. MAX Industrial Microwave: https://www.maxindustrialmicrowave.com

5. Marel: https://marel.com

Telephone :+86-531-55583139

Telephone :+86-531-55583139 WhatsApp :+86 13256674591

WhatsApp :+86 13256674591 Email :

Email :