The Ultimate Almond Microwave Dryer Machine Guide to 2024

Overview of Almond Drying Processes

Almond Microwave Dryer Machine is a crucial step in the almond processing industry, ensuring the preservation of quality and extending shelf life. The process involves reducing the moisture content of almonds to a safe level for storage and consumption. Traditional methods such as sun drying or hot air drying have been used historically, but modern techniques like microwave drying have gained prominence due to their efficiency and effectiveness.

Almond drying typically begins with the harvesting of mature almonds from orchards. After harvest, the almonds undergo cleaning to remove any debris or foreign materials. Once cleaned, the almonds are sorted based on size and quality before being subjected to the drying process.

The drying process aims to remove excess moisture from the almonds while preserving their nutritional value and flavor. Excessive moisture content can lead to spoilage and the growth of mold and bacteria, making proper drying essential for food safety. Various methods are employed for almond drying, with microwave drying emerging as a prominent technology in recent years due to its rapid and uniform heating capabilities.

Microwave dryer machines are specially designed equipment used in the drying of almonds and other food products. These machines utilize electromagnetic waves to generate heat within the almonds, effectively removing moisture from the inside out. Compared to traditional drying methods, microwave drying offers several advantages, including shorter drying times, higher energy efficiency, and better retention of nutritional content and flavor.

Introduction to Microwave Dryer Machines

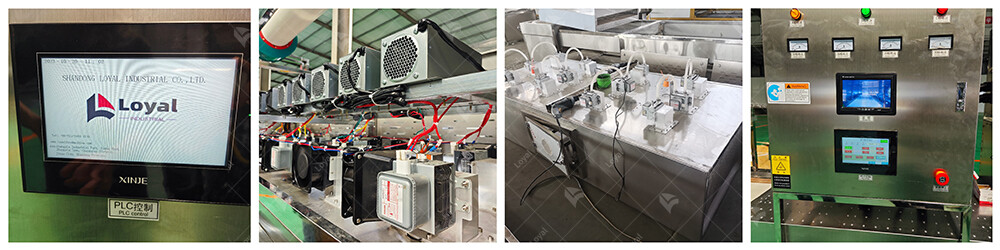

Microwave dryer machines are sophisticated equipment designed to facilitate the drying of various food products, including almonds. These machines utilize microwave radiation to generate heat within the product, allowing for rapid and uniform drying. The microwave drying process involves the absorption of electromagnetic waves by water molecules present in the almonds, causing them to vibrate and generate heat.

The design of microwave dryer machines typically consists of a chamber where the almonds are placed for drying, along with a microwave generator that produces the electromagnetic waves. The chamber is equipped with a conveyor belt or tray system to facilitate the movement of almonds through the drying process.

One of the key advantages of microwave dryer machines is their ability to achieve rapid drying times. The electromagnetic waves penetrate the almonds and heat them from the inside out, resulting in faster moisture removal compared to conventional drying methods. This not only reduces processing time but also helps preserve the natural color, flavor, and nutritional content of the almonds.

Furthermore, microwave dryer machines offer excellent temperature control, ensuring that the almonds are dried uniformly without the risk of over-drying or scorching. This precision in drying helps maintain product quality and consistency, making microwave drying a preferred choice for many almond processors.

Importance of Drying in Almond Processing

Drying is a crucial step in the almond processing industry, playing a pivotal role in preserving the quality and extending the shelf life of almonds. Proper drying ensures that almonds maintain their nutritional value, flavor, and texture while preventing spoilage due to excess moisture content. Almond drying also facilitates easier storage, transportation, and packaging, making them suitable for various culinary and industrial applications.

Almond drying is particularly significant in the almond processing chain as it directly impacts the overall quality of the final product. Improper drying methods or inadequate drying can lead to mold growth, rancidity, and loss of sensory attributes, thereby diminishing the market value of almonds. Therefore, investing in efficient drying techniques is paramount for almond producers to maintain product integrity and meet consumer demands for premium quality almonds.

To address the drying needs of the almond processing industry, various types of drying equipment are available, each offering distinct advantages and capabilities. Among these, microwave dryer machines have gained considerable attention for their ability to provide rapid and uniform drying while preserving the nutritional profile and sensory attributes of almonds.

Types of Microwave Dryer Machines for Almond Drying

1. Batch Microwave Dryers:Batch microwave dryer machines are designed to process a specific quantity of almonds at a time. Almonds are spread evenly on trays or conveyor belts and exposed to microwave radiation in a controlled environment. This method allows for precise control over drying parameters such as temperature, humidity, and exposure time, ensuring consistent results batch after batch.

2. Continuous Microwave Dryers:Continuous microwave dryer machines offer a continuous drying process, ideal for large-scale almond processing operations. Almonds are continuously fed into the dryer system and exposed to microwave radiation as they move along a conveyor belt or through a tunnel. This continuous operation ensures high throughput and efficiency, making it suitable for industrial-scale almond drying applications.

3. Hybrid Microwave-Infrared Dryers:Hybrid microwave-infrared dryer machines combine the benefits of microwave and infrared heating technologies for almond drying. This hybrid approach allows for faster and more energy-efficient drying compared to conventional methods. By leveraging the synergistic effects of both technologies, these dryers achieve rapid moisture removal while minimizing heat damage to almonds, resulting in superior product quality.

4. Vacuum Microwave Dryers:Vacuum microwave dryer machines utilize vacuum technology to remove moisture from almonds at lower temperatures, reducing the risk of heat-induced damage. By operating under vacuum conditions, these dryers facilitate faster moisture evaporation and preserve the nutritional integrity and sensory characteristics of almonds. Vacuum microwave drying is particularly suitable for delicate almonds or those prone to oxidative degradation.

Key Components of Microwave Dryer Machines:

Microwave dryer machines for almond drying comprise several essential components that work in tandem to achieve efficient and effective drying results.

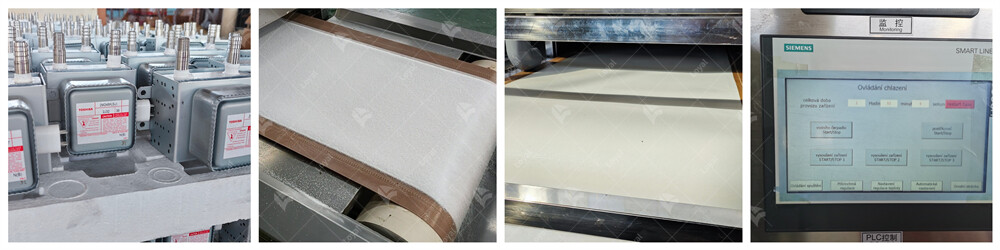

One of the primary components of a microwave dryer machine is the microwave generator, which produces the electromagnetic waves necessary for the drying process. These waves are emitted at specific frequencies tailored to the moisture content of almonds, ensuring optimal drying without compromising quality.

Another crucial component is the microwave chamber, where the almonds are placed for drying. This chamber is designed to allow for uniform exposure of the almonds to the microwave radiation, ensuring consistent drying throughout the batch.

The conveyor system is also integral to microwave dryer machines. It facilitates the movement of almonds through the drying chamber, ensuring even exposure to the microwave radiation and efficient removal of moisture.

Additionally, microwave dryer machines are equipped with sensors that monitor various parameters such as temperature, moisture level, and airflow. These sensors provide real-time data to control systems, allowing for precise adjustment of drying conditions to optimize performance.

Advantages of Microwave Drying Technology:

Microwave drying technology offers several advantages over conventional drying methods, making it an attractive option for almond processing operations.

One key advantage is rapid drying. Microwave radiation penetrates the almonds and heats them from the inside out, resulting in significantly faster drying times compared to traditional methods. This can lead to increased throughput and overall productivity.

Moreover, microwave drying is known for its ability to achieve uniform drying. The electromagnetic waves penetrate the almonds evenly, ensuring that moisture is removed consistently throughout the batch. This helps maintain the quality of the almonds and reduces the risk of over-drying or under-drying.

Another advantage of microwave drying technology is its energy efficiency. By directly heating the almonds rather than heating the surrounding air, microwave drying requires less energy and results in lower operating costs.

Microwave drying offers flexibility in terms of control and customization. Operators can adjust various parameters such as power level, drying time, and temperature to achieve the desired results, making it suitable for a wide range of almond varieties and processing requirements.

Efficiency Enhancement Techniques in Almond Drying

Efficiency in almond drying processes is crucial for maximizing productivity and minimizing resource consumption. One of the most effective ways to enhance efficiency is by employing advanced technology such as the Almond Microwave Dryer Machine. These machines utilize microwave energy to rapidly and evenly dry almonds, significantly reducing processing time compared to traditional methods. Additionally, the precise control and uniform heating provided by microwave dryers ensure consistent quality and reduce product losses, further enhancing overall efficiency.

To further boost efficiency in almond drying, optimizing the operating parameters of the microwave dryer machine is essential. Parameters such as temperature, humidity, and airflow must be carefully monitored and adjusted to achieve optimal drying conditions for almonds. By fine-tuning these parameters, operators can maximize drying rates while minimizing energy consumption and ensuring the quality of the final product.

Another key efficiency enhancement technique is the implementation of automation and remote monitoring systems in almond drying facilities. These systems enable real-time monitoring of drying processes and allow operators to remotely control and adjust dryer settings as needed. By streamlining operations and reducing the need for manual intervention, automation can significantly improve overall efficiency and productivity in almond processing plants.

Integrating energy-efficient practices into almond drying operations can further enhance efficiency and sustainability. This includes investing in energy-efficient equipment, optimizing process layouts to minimize energy losses, and implementing energy management systems to track and reduce energy consumption. By reducing energy usage and greenhouse gas emissions, almond drying facilities can minimize their environmental footprint while simultaneously improving operational efficiency.

Environmental Impact and Sustainability in Microwave Drying

The adoption of microwave drying technology for almond processing offers several environmental benefits compared to traditional drying methods. One significant advantage is the reduced energy consumption associated with microwave drying. Almond Microwave Dryer Machines utilize electromagnetic waves to heat almonds directly, which is more energy-efficient compared to conventional drying methods that rely on hot air convection. As a result, microwave drying can help reduce greenhouse gas emissions and mitigate environmental impact.

Microwave drying offers faster processing times compared to conventional drying methods, leading to lower overall energy consumption and reduced carbon emissions. The rapid and uniform heating provided by microwave dryers allows almonds to be dried more quickly, minimizing the need for prolonged drying periods and further reducing energy usage.

Microwave drying technology offers superior product quality and preservation compared to traditional drying methods. The precise control and uniform heating provided by microwave dryers ensure that almonds retain their nutritional value, flavor, and appearance, resulting in higher-quality products that command premium prices in the market. This not only benefits producers financially but also promotes sustainability by reducing food waste and maximizing the utilization of agricultural resources.

The compact size and versatility of microwave dryer machines make them suitable for small-scale and decentralized almond processing operations, reducing the need for large centralized facilities and transportation networks. This decentralized approach can help minimize environmental impact by reducing the carbon footprint associated with transportation and distribution.

Maintenance and Troubleshooting of Microwave Dryer Machines

Maintenance is essential to ensure the optimal performance and longevity of microwave dryer machines in almond processing facilities. Regular upkeep and adherence to troubleshooting protocols can prevent downtime and costly repairs.

To maintain microwave dryer machines effectively, routine inspections and cleaning procedures must be conducted. Components such as the magnetron, waveguide, and cooling system should be inspected for signs of wear or damage. Cleaning should involve removing any food debris or residue that may accumulate inside the machine, as this can affect its performance.

Regular calibration of microwave power levels is crucial to ensure uniform drying of almonds. This calibration process involves verifying the output power of the microwave generator and adjusting it as needed to maintain consistency in drying results. Additionally, the seals and gaskets should be inspected and replaced if worn to prevent leakage of microwave energy.

Troubleshooting microwave dryer machines requires a systematic approach to identify and resolve issues promptly. Common problems include uneven drying, power fluctuations, and mechanical malfunctions. When troubleshooting, technicians should check for loose connections, damaged components, or foreign objects obstructing the microwave transmission.

Regular maintenance schedules should be established and documented, detailing tasks such as cleaning, calibration, and inspection intervals. This proactive approach helps prevent unexpected breakdowns and ensures uninterrupted operation of microwave dryer machines in almond processing facilities.

Innovations and Trends in Almond Drying with Microwave Dryer Machines

One notable innovation is the integration of advanced sensor technologies into microwave dryer machines. These sensors monitor various parameters such as moisture content, temperature, and airflow, allowing for real-time adjustments to optimize drying conditions and reduce energy consumption.

Another trend is the adoption of automation and digitalization in almond drying processes. Automated systems equipped with machine learning algorithms can analyze data from sensors and adjust drying parameters dynamically to achieve precise and consistent results. Furthermore, digital platforms enable remote monitoring and control of microwave dryer machines, enhancing operational efficiency and flexibility.

Sustainability is a key focus area in almond drying, with a growing emphasis on reducing energy consumption and minimizing environmental impact. Microwave dryer machines equipped with energy-efficient components and eco-friendly materials are gaining traction in the industry. Additionally, the use of renewable energy sources such as solar power for operating microwave dryer machines is becoming more widespread.

Overall, ongoing research and development efforts continue to drive innovation and improvement in almond drying with microwave dryer machines. From advanced sensor technologies to sustainable practices, these innovations and trends are shaping the future of almond processing, ensuring higher quality products and reduced environmental footprint.

References

1.Tetra Pak : https://www.tetrapak.com

2.Jinan Kelid Machinery Co., Ltd.: http://www.kldfoodmachine.com

3. GEA : https://www.gea.com

4. MAX Industrial Microwave: https://www.maxindustrialmicrowave.com

5. Marel: https://marel.com

Telephone :+86-531-55583139

Telephone :+86-531-55583139 WhatsApp :+86 13256674591

WhatsApp :+86 13256674591 Email :

Email :