Everything You Need To Know About Shrimp Thawing Machine In 2024

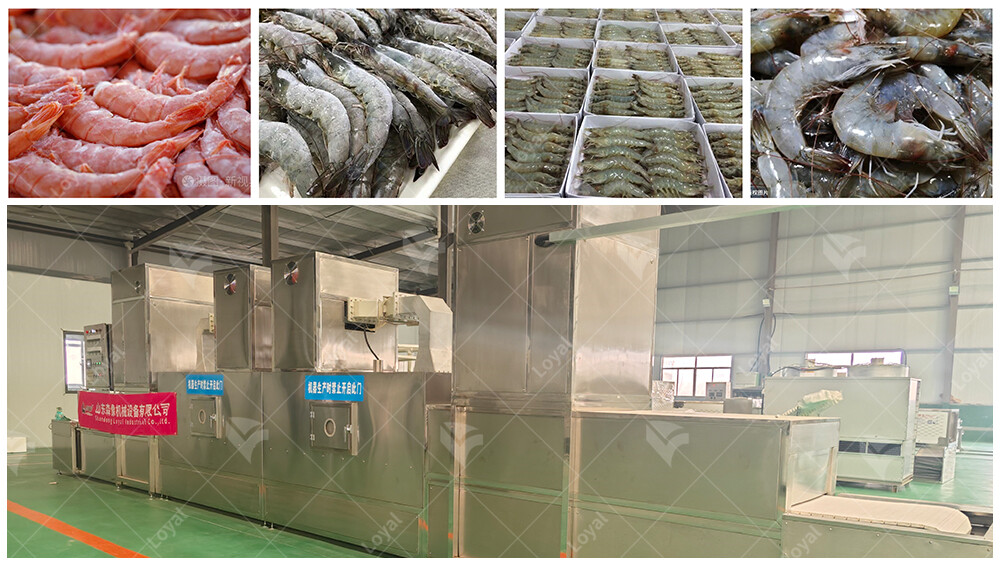

In the fast-paced world of seafood processing, the Shrimp Thawing Machine emerges as a pivotal player, revolutionizing the way shrimp are thawed and prepared. As we navigate through 2024, this cutting-edge device continues to redefine industry standards, offering efficiency, quality preservation, and sustainability in seafood processing.

What Is Industrial Microwave Defrost and Thawing Machine

Industrial microwave defrosting is a cutting edge method employed in the food industry to thaw frozen seafood rapidly and efficiently. Thawing Equipment for High Quality Seafood is at the forefront of this technology, providing solutions for businesses aiming to streamline their operations. The process involves utilizing microwave tempering systems specifically designed for the task.

Microwave thawing is particularly advantageous for seafood such as shrimp, with Frozen Shrimp Thawing Machine being a notable application. Unlike traditional methods that can be time consuming and result in uneven thawing, microwave defrosting offers a quick and uniform solution. By employing Industrial Microwave Defrost and Thawing Machines, businesses can significantly reduce thawing times while maintaining product quality.

The principle behind defrosting shrimp with microwaves lies in the ability of microwaves to penetrate the frozen product efficiently. These electromagnetic waves agitate water molecules within the shrimp, generating heat and causing the ice to melt rapidly. This process ensures that the shrimp thaw evenly without compromising their texture or taste.

Shrimp Thawing Machine Differences From Traditional Thawing Methods

Among the various applications of this technology, Frozen Shrimp Microwave Thawing stands out as a game-changer in the seafood industry. Unlike conventional thawing methods that often result in uneven thawing and loss of moisture, microwave thawing offers a rapid and uniform thawing process.

When comparing Defrosting Shrimp With Microwaves to traditional methods such as room temperature thawing or water immersion, the advantages are evident. Microwave thawing significantly reduces the time required to thaw shrimp while minimizing the risk of bacterial growth, ensuring food safety and quality.

Furthermore, Microwave Tempering Systems provide precise control over the thawing process, allowing seafood processors to tailor the thawing parameters to specific product requirements. This level of control is crucial in ensuring consistent quality and meeting the demands of discerning consumers.

In the quest for efficiency and quality, the Industrial Microwave Defrost and Thawing Machine emerges as a versatile solution for seafood processing facilities. With its ability to handle large volumes of seafood while maintaining quality standards, it represents a significant advancement in the field of food technology.

Types Of Shrimp Thawing Machine for Shrimp

1. Microwave Shrimp Thawing Machine: This type utilizes controlled microwave waves to penetrate the shrimp, ensuring a swift and uniform thawing process. The efficiency of microwave technology has made it a popular choice in seafood processing facilities.

2. Water Immersion Shrimp Thawing Machine: In this type, shrimp are submerged in temperature-controlled water, promoting a gradual thawing process. It is known for preserving the texture and taste of the shrimp effectively.

3. Air Circulation Shrimp Thawing Machine: Using a system of circulating air, this type facilitates an even thawing process. It is particularly suitable for large-scale operations where uniformity is paramount.

4. High-Pressure Processing Shrimp Thawing Machine: This innovative type employs high-pressure conditions to expedite the thawing process. It's recognized for its speed and ability to handle a high volume of shrimp.

5. Chemical Defrosting Shrimp Thawing Machine: Chemical agents are used in this type to accelerate the thawing process. It is chosen for its rapid results and precise control over the thawing conditions.

Understanding the specific requirements of your seafood processing facility is essential in selecting the most suitable type of Shrimp Thawing Machine.

Application of Shrimp Thawing Machine

1. Seafood Processing Plants: The primary application of the Shrimp Thawing Machine is in seafood processing plants, where the demand for efficient and quality thawing is at its peak. The machine seamlessly integrates into the processing line, enhancing overall productivity.

2. Restaurants and Catering Services: Restaurants and catering services benefit significantly from the Shrimp Thawing Machine. Its quick thawing capabilities ensure that chefs have a constant supply of thawed shrimp, facilitating smooth kitchen operations.

3. Seafood Export Industry: In the seafood export industry, where maintaining the quality of products during transportation is crucial, the Shrimp Thawing Machine plays a pivotal role. It ensures that shrimp reach their destination in optimal condition, meeting international quality standards.

4. Frozen Food Retailers: Frozen food retailers, aiming to provide convenient and high-quality products to consumers, find value in the Shrimp Thawing Machine. It enables them to offer thawed shrimp with preserved quality, meeting consumer preferences.

5. Food Processing Laboratories: Food processing laboratories involved in research and development of seafood products benefit from the precision and consistency offered by the Shrimp Thawing Machine. It becomes an essential tool for conducting experiments and maintaining product quality.

Using Microwave Technology to Improve Shrimp Thawing Production Efficiency

At the forefront of innovation, the Shrimp Thawing Machine employs advanced microwave technology to enhance the efficiency of shrimp thawing production. This state-of-the-art approach utilizes controlled microwave waves, penetrating the shrimp with precision and agitating water molecules. This results in a swift and uniform thawing process, addressing the demand for speed and consistency in seafood processing.

In 2024, the integration of microwave technology into shrimp thawing signifies a paradigm shift, allowing seafood processing facilities to meet the escalating demands of the market. The use of controlled microwave waves not only expedites the thawing process but also ensures the preservation of the shrimp's texture and taste, aligning with the industry's commitment to quality.

Choosing the Right Of Shrimp Thawing Machine

Selecting the appropriate machinery for shrimp thawing is a critical decision that impacts production efficiency and quality. The Shrimp Thawing Machine offers a range of options, and choosing the right machinery involves a nuanced understanding of the specific needs and scale of the seafood processing facility.

Technical Parameter Of Microwave Thawing Machine | |||||

Model | Power | Output | Specification | Allocation | Control |

LY-25KW-F(S) | 25KW | 300-500KG/H | 9000X1500X2400MM | Water/air cooling | PLC |

LY-50KW-F(S) | 50KW | 600-1000KG/H | 12000X1500X2400MM | Water/air cooling | PLC |

LY-100KW-F(S) | 100KW | 1200-1500KG/H | 18000X1500X2400MM | Water/air cooling | PLC |

Notes: | |||||

1. Power supply: 380V±10% 50Hz±1% ,Three-Phase Five-Wire, (must be equipped with a dedicated ground wire) | |||||

2. Microwave frequency: 915MHz | |||||

3. Input power: 25-125kVA | |||||

4. Microwave output power: 20-100kw (adjustable) | |||||

Key Features To Consider In Shrimp Thawing Machine

1. Thawing Time: The efficiency of a Shrimp Thawing Machine is often measured by its thawing time. Consider machines that offer rapid thawing without compromising the quality of the shrimp.

2. Temperature Control: Precision in temperature control is crucial to preserving the texture and taste of the shrimp. Look for machines with advanced temperature regulation features.

3. Batch Size Capacity: Evaluate the machine's capacity concerning the volume of shrimp your facility processes. Opt for a machine that aligns with your production requirements.

4. Energy Efficiency: In the era of sustainability, choosing an energy-efficient Shrimp Thawing Machine is not just environmentally responsible but also cost-effective for your business.

5. User-Friendly Interface: A user-friendly interface ensures smooth operation and reduces the chances of errors. Consider machines with intuitive controls and easy maintenance.

Maintaining Your Shrimp Thawing Machine Essential Tips for Daily Care

Regular inspection and cleaning of your Microwave Tempering Systems are crucial for preventing malfunctions and maintaining hygiene standards. Start by examining the interior components for any signs of wear or damage. Clean the surfaces with a mild detergent solution and sanitize them with a food-safe disinfectant. Pay special attention to the microwave emitter and ensure it's free from any residue buildup that could interfere with the thawing process.

The Industrial Microwave Defrost and Thawing Machine should be monitored closely during operation to ensure consistent performance. Check the temperature settings regularly and make adjustments as needed to achieve the desired thawing rate for different shrimp products. Additionally, keep an eye on the machine's power supply and electrical connections to prevent overheating or electrical faults.

Calibration is essential to maintain the accuracy and efficiency of the Frozen Shrimp Microwave Thawing process. Periodically calibrate the machine according to the manufacturer's instructions, taking into account factors such as shrimp size, density, and packaging. This will ensure uniform thawing results and minimize product waste due to under or over-thawing.

To prevent friction and wear, lubricate the moving parts of your Defrosting Shrimp With Microwaves machine regularly. Use a food-grade lubricant recommended by the manufacturer to ensure compatibility with the machine components. Focus on areas such as conveyor belts, bearings, and hinges, and follow the lubrication schedule outlined in the maintenance manual.

Finally, invest in training programs to educate your staff on the proper operation and maintenance procedures for the Shrimp Thawing Machine. Emphasize the importance of adherence to safety protocols and best practices to prevent accidents and equipment damage. Encourage employees to report any issues or abnormalities they encounter during operation promptly.

Advantages Of Using A Shrimp Thawing Machine

1. Efficiency: The foremost advantage of employing a Shrimp Thawing Machine is its unparalleled efficiency. This cutting-edge device utilizes advanced technology to ensure a rapid and uniform thawing process. By harnessing controlled microwave waves, the machine penetrates the shrimp, agitating water molecules and accelerating the thawing process.

2. Preservation of Quality: Quality preservation stands as a hallmark feature of the Shrimp Thawing Machine. As it swiftly thaws shrimp, the advanced technology prevents any compromise in texture or taste. This preservation of quality is vital for businesses aiming to deliver premium-grade shrimp to discerning consumers.

3. Consistency: Consistency in thawing is a crucial aspect that the Shrimp Thawing Machine excels in. The controlled microwave technology ensures that each shrimp undergoes a consistent thawing process, eliminating variations and meeting the high standards of the seafood industry.

4. Large-scale Processing: For seafood processing facilities dealing with high volumes, the Shrimp Thawing Machine proves indispensable. Its efficiency allows for the handling of large batches of shrimp with speed and precision, streamlining operations and ensuring a steady supply of thawed shrimp.

5. Energy Efficiency: Embracing sustainability, the Shrimp Thawing Machine incorporates energy-efficient design. This not only reduces operational costs but also aligns with the broader industry trend towards eco-friendly practices.

Understanding The Role Of Shrimp Thawing Machine in Shrimp

The role of the Shrimp Thawing Machine goes beyond the simple task of thawing shrimp. It plays a crucial role in preserving the quality and integrity of the shrimp during the thawing process. The controlled microwave waves utilized by the machine penetrate the shrimp, ensuring a rapid and uniform thawing process. This not only saves time but also guarantees that each shrimp retains its texture and taste, meeting the high standards of the seafood industry.

In seafood processing facilities around the world, the Shrimp Thawing Machine is becoming an indispensable tool, streamlining operations and contributing to the efficiency of the overall process. As we delve into 2024, understanding the intricate role of this machine becomes paramount for businesses striving to deliver premium-quality thawed shrimp to the market.

Selecting The Best Microwave Shrimp Thawing Equipment

Choosing the right equipment for thawing shrimp is a critical decision for seafood processors. The market is flooded with options, but the quest for the best Microwave Shrimp Thawing Equipment requires careful consideration. The ideal equipment should not only possess advanced thawing technology but also align with the specific needs and volume requirements of the seafood processing facility.

In 2024, the selection process involves a meticulous evaluation of various Microwave Shrimp Thawing Equipment options available. The emphasis is on finding equipment that not only meets industry standards but also integrates seamlessly into existing processing workflows. The goal is to enhance efficiency without compromising on the quality of the thawing process.

Expertise Of Engineers In Microwave Shrimp Thaw

Microwave technology has become a cornerstone in the seafood industry, and the expertise of engineers in utilizing this technology for shrimp thawing is unparalleled. In 2024, these professionals are at the forefront of innovation, employing their in-depth knowledge to optimize the performance of the Shrimp Thawing Machine. Engineers bring a profound understanding of microwave waves, ensuring precise and controlled thawing that preserves the shrimp's texture and taste.

The success of microwave shrimp thawing lies in the ability of engineers to fine-tune the Shrimp Thawing Machine. They leverage their expertise to calibrate the machine's settings, ensuring that each shrimp undergoes a consistent and efficient thawing process. This level of precision is a testament to the skills and dedication of engineers, making microwave shrimp thawing a reliable and sought-after method in 2024.

Importance Of Quality Control In Shrimp Thawing Machine

In the dynamic landscape of seafood processing, quality control is a non-negotiable aspect, especially in the context of the Shrimp Thawing Machine. Quality control measures are meticulously implemented to guarantee that each shrimp thawed meets the highest standards of the industry. Engineers play a pivotal role in developing and implementing these control mechanisms, ensuring the output is not only rapid but consistently of premium quality.

The Shrimp Thawing Machine, underpinned by rigorous quality control, becomes a reliable asset for businesses aiming to deliver top-tier shrimp products. Engineers employ advanced monitoring systems and feedback loops, enabling real-time adjustments to maintain optimal thawing conditions. This commitment to quality control sets the Shrimp Thawing Machine apart, making it an indispensable tool for seafood processors in 2024.

Businesses adopting the Shrimp Thawing Machine not only embrace cutting-edge technology but also participate in a sustainable seafood future. Engineers play a pivotal role in ensuring that advancements in the Shrimp Thawing Machine align with and contribute to the industry's evolving sustainability goals.

Latest Innovations in Shrimp Thawing Machine

Significant leap forward in the realm of Shrimp Thawing Machine technology. The latest innovations focus on enhancing the efficiency and precision of the thawing process. One notable advancement is the integration of artificial intelligence (AI) algorithms, which optimize thawing parameters based on the specific characteristics of each shrimp batch. This ensures a tailored and uniform thawing experience, contributing to the overall quality of the final product.

Additionally, the incorporation of smart sensors in Shrimp Thawing Machines allows real-time monitoring of the thawing process. These sensors provide valuable data on temperature, moisture levels, and shrimp consistency, enabling operators to make instant adjustments for optimal results. This level of technological sophistication ensures not only speed but also a meticulous attention to detail in the shrimp thawing process.

Advances in Shrimp Thawing Machine

In the quest for delivering premium-quality shrimp, the focus on preserving the texture and taste of the shrimp during the thawing process remains paramount. Advanced Shrimp Thawing Machines in 2024 prioritize quality preservation through controlled microwave waves. These machines delicately thaw each shrimp, maintaining its integrity and ensuring a delightful culinary experience for consumers.

Efficiency is a key driver of innovation in Shrimp Thawing Machines. The latest models are designed to handle larger quantities of shrimp with increased speed, addressing the demands of high-volume seafood processing. This not only accelerates production timelines but also contributes to meeting the growing global demand for thawed shrimp.

References

To delve deeper into the realm of microwave processes, referring to authoritative literature is imperative. Established journals, academic publications, and industry reports serve as reliable references for gaining in-depth knowledge about the principles and advancements in microwave technology, specifically in the context of shrimp thawing.

1. IEEE Xplore (https://ieeexplore.ieee.org/): IEEE Xplore offers academic journals, conference papers, and standards in the fields of electrical engineering, computer science, and electronics. It stands as a authoritative academic resource.

2. ScienceDirect (https://www.sciencedirect.com/): Published by Elsevier, ScienceDirect is a comprehensive full-text database spanning multiple disciplines, including physical sciences and engineering.

3. SpringerLink (https://link.springer.com/): SpringerLink is an online platform for academic journals, books, and conference papers published by Springer. It covers a wide range of disciplinary areas.

4. Wiley Online Library (https://onlinelibrary.wiley.com/): Wiley Online Library provides academic journals, books, and online reference resources from Wiley Publishers, encompassing physical sciences and engineering.

5. Taylor & Francis Online (https://www.taylorandfrancis.com/): Taylor & Francis Online offers academic journals and books from Taylor & Francis Publishers, spanning various disciplines, including engineering technology and physical sciences.

These websites serve as reliable sources for authoritative literature and research in the field of microwave processes and related technologies.

Shrimp Thawing Machine Frequently Asked Questions (FAQs)

Shrimp Thawing Machine, a revolutionary technology in seafood processing, has been a subject of curiosity and interest. To provide comprehensive insights, let's explore the frequently asked questions (FAQs) surrounding this innovative device.

1. What is a Shrimp Thawing Machine?

The Shrimp Thawing Machine is an advanced device specifically designed for thawing shrimp efficiently and rapidly. In 2024, this cutting-edge technology has gained prominence in the seafood industry, offering a solution that ensures quick and uniform thawing while preserving the quality of the shrimp.

2. How does the Shrimp Thawing Machine work?

At the core of the Shrimp Thawing Machine lies its intricate working principle. This device employs controlled microwave waves that penetrate the shrimp, agitating water molecules and resulting in swift and uniform thawing. The method not only ensures speed but also preserves the shrimp's texture and taste.

3. What are the advantages of using a Shrimp Thawing Machine?

The Shrimp Thawing Machine offers several advantages. Its efficiency in rapid thawing allows seafood processing facilities to handle large quantities with ease, meeting the demands of the market. Additionally, the controlled microwave technology ensures quality preservation, making it a valuable asset for businesses aiming to deliver premium shrimp products.

4. Are there challenges associated with operating a Shrimp Thawing Machine?

While the Shrimp Thawing Machine is a technological marvel, challenges can arise in its operation. It is crucial for operators to be well-versed in the machine's settings and maintenance to ensure optimal performance. Regular monitoring and preventive measures are essential to address potential issues.

5. How does the Shrimp Thawing Machine contribute to sustainability in seafood processing?

In the context of 2024's sustainability goals, the Shrimp Thawing Machine aligns with eco-friendly practices. Its advanced technology minimizes energy consumption, contributing to a more environmentally conscious approach to seafood processing. Businesses embracing such sustainable technologies not only enhance their operational efficiency but also appeal to environmentally conscious consumers.

Conclusion

In wrapping up our exploration of the Shrimp Thawing Machine FAQs, it is evident that this innovative technology stands at the forefront of reshaping the future of seafood processing. The intricate working principles, efficiency, quality assurance, and sustainability aspects underscore its significance in the dynamic landscape of 2024. As businesses strive to meet and exceed consumer expectations, the Shrimp Thawing Machine emerges as a pivotal tool, ensuring not only rapid thawing but also the preservation of the shrimp's texture and taste.

As we step into the future, the trajectory of the Shrimp Thawing Machine is poised for continued innovation and progress. The industry's focus on efficiency, quality, and sustainability aligns seamlessly with the attributes of this cutting-edge technology. Whether it's the application of microwave technology, the selection of the right machine, or the role of engineers in advancing the field, the Shrimp Thawing Machine remains a beacon of progress. With trends evolving and new innovations on the horizon, the Shrimp Thawing Machine promises to lead the way in shaping the future of seafood processing, ushering in an era of heightened efficiency, quality, and sustainability.

Telephone :+86-531-55583139

Telephone :+86-531-55583139 WhatsApp :+86 13256674591

WhatsApp :+86 13256674591 Email :

Email :