Everything you Need to Know About Raisin Tunnel Type Microwave Drying Machine

Introduction to Microwave Drying Technology

Microwave drying technology revolutionizes the food processing industry by offering rapid and efficient drying solutions. Raisin Tunnel Type Microwave Drying Machines exemplify this advancement, catering to the specific needs of food manufacturers. These machines utilize microwave radiation to remove moisture from raisins, ensuring preservation without compromising flavor or nutritional value.

Microwave drying operates on the principle of dielectric heating, where water molecules within the food material absorb microwave energy, leading to their rapid excitation and subsequent evaporation. This process significantly reduces drying time compared to conventional methods, making it highly desirable for industrial applications.

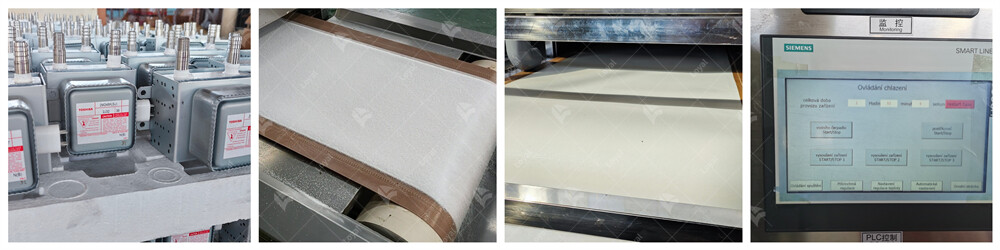

Raisin Tunnel Type Microwave Drying Machines consist of a conveyor belt system enclosed within a tunnel-like chamber. The raisins are evenly spread on the conveyor belt, allowing for uniform exposure to microwave radiation. As the belt moves through the chamber, the raisins undergo consistent drying, resulting in high-quality end products.

The versatility of microwave drying technology extends beyond raisins to various food products, including fruits, vegetables, herbs, and meats. Its precise control over drying parameters ensures optimal moisture removal while preserving taste, texture, and nutritional content. As the demand for healthier and more convenient food options rises, microwave drying technology continues to play a pivotal role in meeting these requirements.

Understanding the Importance of Drying in Food Processing

Drying is a critical stage in food processing, indispensable for preserving perishable goods, extending shelf life, and preventing microbial growth. Raisin Tunnel Type Microwave Drying Machines exemplify the significance of efficient drying methods in maintaining product quality and safety standards.

In food processing, moisture removal is essential to prevent spoilage and enhance stability. By reducing water activity, drying inhibits the growth of bacteria, yeast, and mold, thereby ensuring the microbiological safety of food products. Raisins, with their naturally high sugar content, are particularly susceptible to microbial contamination if not properly dried, underscoring the importance of reliable drying technologies.

Moreover, drying plays a crucial role in enhancing flavor concentration and aroma development. By removing excess moisture, the natural sugars and flavors in fruits like raisins become more concentrated, resulting in a richer and more pronounced taste profile. Raisin Tunnel Type Microwave Drying Machines excel in preserving the sensory attributes of raisins, ensuring a superior product that meets consumer expectations.

Additionally, efficient drying methods contribute to resource conservation and waste reduction in food production. By minimizing moisture content, manufacturers can reduce packaging requirements and transportation costs while maximizing product yield. This optimization aligns with sustainability goals and promotes eco-friendly practices within the food industry, further underscoring the importance of advanced drying technologies like microwave drying.

Exploring the Advantages of Microwave Drying Machines

Microwave drying machines offer a plethora of advantages over traditional drying methods, revolutionizing the food processing industry. One significant advantage is the speed of drying. Unlike conventional methods that may take hours or even days, microwave drying significantly reduces drying time, thus enhancing productivity and efficiency. This rapid drying process is particularly beneficial for industries with high production demands, such as the raisin processing industry.

Another advantage is the preservation of nutritional quality. Microwave drying operates at lower temperatures compared to conventional methods, minimizing heat damage to the product. This gentle drying process helps retain the natural color, flavor, and nutritional content of raisins, ensuring a higher quality end product. Additionally, the controlled heating provided by microwave technology helps mitigate the risk of over-drying or burning, further preserving the sensory and nutritional characteristics of the raisins.

Moreover, microwave drying machines offer versatility in processing various types of raisins and other food products. These machines can accommodate different sizes, shapes, and moisture levels of raisins, allowing for flexibility in production. Whether it's large-scale commercial operations or small-batch artisanal processing, microwave drying machines can be tailored to meet specific processing requirements, making them suitable for a wide range of applications within the food industry.

Furthermore, microwave drying machines are known for their energy efficiency and environmental sustainability. By utilizing electromagnetic waves to generate heat directly within the product, these machines minimize energy wastage associated with heating the surrounding air, as seen in conventional drying methods. This not only reduces operating costs for food processors but also contributes to a lower carbon footprint, aligning with the growing demand for sustainable practices in food production. Overall, the advantages of microwave drying machines make them a preferred choice for raisin processing and other food manufacturing applications, offering improved efficiency, quality, and sustainability compared to traditional drying methods.

Components and Working Principle of Raisin Tunnel Type Microwave Drying Machine

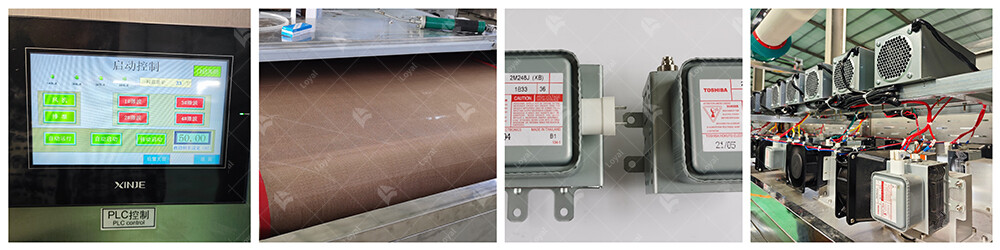

The raisin tunnel type microwave drying machine comprises several essential components that work together to facilitate the drying process. One key component is the microwave generator, which produces electromagnetic waves at a specific frequency, typically around 2450 MHz for industrial applications. These waves are then transmitted into the drying chamber, where the raisins are placed on a conveyor belt for processing.

Within the drying chamber, a magnetron converts electrical energy into microwave radiation, which penetrates the raisins and generates heat through dielectric heating. This process occurs as the polar molecules within the raisins, such as water molecules, rapidly realign with the changing electromagnetic field, generating friction and heat in the process. As a result, the moisture within the raisins evaporates, leading to drying.

The conveyor belt within the drying chamber facilitates continuous processing, allowing for a steady flow of raisins through the machine. The speed of the conveyor belt can be adjusted to control the residence time of the raisins within the drying chamber, ensuring optimal drying conditions.

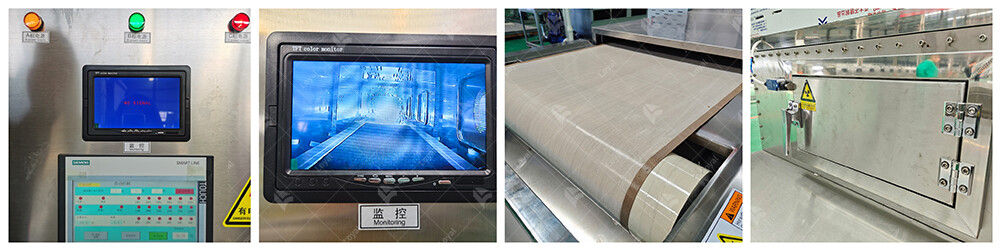

Additionally, the raisin tunnel type microwave drying machine is equipped with temperature and moisture sensors, along with a control system, to monitor and regulate the drying process. This ensures consistent drying performance and allows operators to adjust parameters such as temperature, humidity, and conveyor speed as needed to achieve the desired drying outcomes.

Raisin Drying Methods - Microwave vs. Traditional

Raisin production involves the critical step of drying grapes to the desired moisture content to prevent spoilage and ensure product quality. Two primary methods for drying raisins are microwave drying and traditional drying techniques.

Microwave drying utilizes electromagnetic waves to generate heat directly within the raisin, speeding up the drying process compared to traditional methods. Raisin Tunnel Type Microwave Drying Machine is a sophisticated industrial equipment designed specifically for this purpose. This machine employs a tunnel configuration, allowing for continuous and uniform drying of raisins.

Traditional drying methods, such as sun drying and hot air drying, have been practiced for centuries. Sun drying involves laying out grapes in the open air under the sun, while hot air drying relies on heated air circulation to remove moisture. However, these methods are slower and less efficient compared to microwave drying.

Microwave drying offers several advantages over traditional methods. Firstly, it significantly reduces drying time, thereby increasing productivity and throughput. Secondly, it preserves the natural color, flavor, and nutritional content of raisins better than traditional methods, which often result in heat damage and nutrient loss. Additionally, microwave drying offers precise control over drying parameters, ensuring consistent quality batch after batch.

Despite the benefits of microwave drying, traditional methods still have their place in certain situations. For example, in regions where electricity is unreliable or expensive, sun drying may be a more economical option. Furthermore, some consumers prefer the taste and texture of traditionally dried raisins, perceiving them as more authentic.

Quality Control and Safety Measures in Microwave Drying:

Ensuring product quality and safety is paramount in the food processing industry, including microwave drying of raisins. Several quality control and safety measures are implemented to maintain high standards throughout the drying process.

Raisin Tunnel Type Microwave Drying Machine is equipped with advanced sensors and monitoring systems to precisely control temperature, humidity, and airflow within the drying chamber. Regular calibration and maintenance of these systems are essential to ensure accurate and consistent drying results.

Quality control begins with the selection of raw materials. Only high-quality grapes with uniform size and ripeness are chosen for drying to ensure uniform drying and consistent product quality. Additionally, strict hygiene practices are followed to prevent contamination and maintain product integrity.

During the drying process, frequent inspections are conducted to monitor the progress and quality of raisins. Any deviations from the desired moisture content or signs of overheating are promptly addressed to prevent quality issues. Moreover, samples are periodically taken for laboratory analysis to assess the nutritional content and microbiological safety of the dried raisins.

In terms of safety measures, Raisin Tunnel Type Microwave Drying Machine is designed with multiple layers of protection to prevent accidents and ensure operator safety. These include safety interlocks, emergency stop buttons, and automated shutdown systems in case of malfunction or overheating.

Applications and Industries Utilizing Raisin Tunnel Type Microwave Drying Machines

Raisin Tunnel Type Microwave Drying Machines find extensive applications across various industries due to their efficiency and effectiveness in drying raisins. One prominent sector utilizing these machines is the food processing industry, where raisins are a common ingredient in various products such as cereals, baked goods, and snacks. By employing microwave drying technology, food manufacturers can efficiently dry raisins to the desired moisture content while preserving their nutritional value and flavor.

Another industry benefiting from Raisin Tunnel Type Microwave Drying Machines is the pharmaceutical sector. Raisins are used in some medicinal preparations and pharmaceutical products. The precise control offered by microwave drying ensures that raisins maintain their quality and potency, meeting the stringent standards required for pharmaceutical applications.

The cosmetics industry utilizes raisins in the production of skincare and beauty products. Microwave drying machines play a crucial role in drying raisins used as ingredients in cosmetics formulations. By employing this technology, cosmetic manufacturers can ensure the quality and purity of their products while maintaining efficient production processes.

The agricultural sector utilizes Raisin Tunnel Type Microwave Drying Machines in raisin production facilities. These machines enable farmers and raisin producers to efficiently dry large quantities of raisins, thereby increasing productivity and reducing post-harvest losses. This application is particularly significant in regions with a high volume of raisin production, where efficient drying methods are essential for the success of the industry.

Cost-effectiveness and ROI of Microwave Drying Technology

Investing in Microwave Drying Technology, including Raisin Tunnel Type Microwave Drying Machines, offers significant cost-effectiveness and a high return on investment (ROI) for businesses in the food processing and related industries. One key factor contributing to the cost-effectiveness of this technology is its energy efficiency. Compared to traditional drying methods, such as hot air drying, microwave drying requires less energy consumption, resulting in lower operating costs for businesses.

Moreover, Microwave Drying Technology offers faster drying times compared to conventional methods, leading to increased production throughput and reduced processing times. This efficiency translates into higher productivity and revenue generation for companies utilizing Raisin Tunnel Type Microwave Drying Machines.

Additionally, the precise control and uniform drying provided by microwave technology contribute to higher product quality and reduced product losses due to over-drying or uneven drying. This quality assurance results in lower wastage and improved product consistency, further enhancing the cost-effectiveness of microwave drying technology.

Furthermore, the versatility of Microwave Drying Machines allows businesses to diversify their product offerings and enter new markets. By efficiently drying raisins and other food ingredients, companies can explore opportunities in sectors such as snack foods, confectionery, and health foods, thereby expanding their revenue streams and enhancing overall profitability.

Maintenance and Troubleshooting Guidelines for Raisin Tunnel Type Microwave Drying Machines

Proper maintenance and timely troubleshooting are essential for ensuring the optimal performance and longevity of Raisin Tunnel Type Microwave Drying Machines. Regular maintenance tasks include cleaning the machine components, inspecting for wear and tear, and lubricating moving parts to prevent friction and ensure smooth operation.

It is crucial to monitor the machine's performance regularly and address any deviations from the desired operating parameters promptly. This may involve calibrating sensors, adjusting power settings, or replacing faulty components to maintain consistent drying results.

In the event of malfunctions or breakdowns, prompt troubleshooting is necessary to minimize production disruptions. Troubleshooting procedures may include diagnosing electrical or mechanical issues, checking for blockages or obstructions, and consulting technical documentation or manufacturer support for guidance.

Future Trends and Innovations in Microwave Drying Technology

The future of Microwave Drying Technology, including Raisin Tunnel Type Microwave Drying Machines, is characterized by ongoing innovation and advancements aimed at enhancing efficiency, sustainability, and product quality. One emerging trend is the integration of artificial intelligence (AI) and machine learning algorithms into drying systems to optimize process parameters and enhance control and automation.

There is growing interest in the development of eco-friendly drying solutions that minimize energy consumption and environmental impact. This includes the use of renewable energy sources, such as solar power, and the implementation of novel drying techniques, such as vacuum microwave drying, which can further reduce drying times and energy requirements.

Furthermore, advancements in materials science and engineering are enabling the design of more durable and efficient microwave drying equipment. This includes the use of advanced ceramics and composites for constructing drying chambers and components, as well as the development of novel microwave applicators for more uniform and precise heating.

Overall, the future of Microwave Drying Technology holds promise for continued innovation and evolution, driven by the pursuit of greater efficiency, sustainability, and product quality in various industrial applications, including the drying of raisins and other food products.

References

1.Tetra Pak : https://www.tetrapak.com

2.Jinan Kelid Machinery Co., Ltd.: http://www.kldfoodmachine.com

3. GEA : https://www.gea.com

4. MAX Industrial Microwave: https://www.maxindustrialmicrowave.com

5. Marel: https://marel.com

Telephone :+86-531-55583139

Telephone :+86-531-55583139 WhatsApp :+86 13256674591

WhatsApp :+86 13256674591 Email :

Email :