Everything you need to know about preserved fruit microwave sterilization machine In 2024

Introduction

In 2024, the food processing industry witnesses a significant advancement with the introduction of preserved fruit microwave sterilization machines. These machines represent a cutting-edge technology designed to ensure the safety and quality of preserved fruits through the use of microwave sterilization. With the increasing demand for preserved fruits and the growing awareness of food safety among consumers, understanding the intricacies of preserved fruit microwave sterilization machines becomes paramount.

Preserved fruit microwave sterilization machines utilize microwave technology to efficiently and effectively eliminate harmful microorganisms from preserved fruits while preserving their natural flavor, texture, and nutritional value. This innovative approach offers several advantages over traditional sterilization methods, including faster processing times, reduced energy consumption, and improved preservation of fruit quality. As such, preserved fruit microwave sterilization machines are poised to revolutionize the preserved fruit industry by providing manufacturers with a reliable and efficient method for ensuring the safety and quality of their products.

Working principle

The working principle of a preserved fruit microwave sterilization machine in 2024 is rooted in the utilization of microwave technology to eradicate harmful microorganisms while preserving the quality of the fruit. This advanced machine employs controlled microwave radiation to penetrate the fruit and disrupt the cellular structure of any pathogens present. This process effectively deactivates bacteria, viruses, and molds, ensuring the safety and extended shelf life of the preserved fruit without compromising its taste or nutritional value. Additionally, the machine is engineered to maintain precise temperature and humidity levels to optimize the sterilization process, ensuring consistent and reliable results for various types of preserved fruit. Overall, the working principle of the preserved fruit microwave sterilization machine embodies the fusion of innovative technology and food safety standards, providing a crucial solution for ensuring the quality and safety of preserved fruit products in 2024 and beyond.

Advantages of microwave sterilizer for preserved fruits

Advantages of Microwave Sterilizer for Preserved Fruits |

1. Rapid Sterilization:Microwave sterilization machines offer quick and efficient sterilization of preserved fruits, significantly reducing processing time compared to traditional methods. |

2. Uniform Heating:With microwave technology, preserved fruits are heated uniformly throughout, ensuring thorough sterilization and preserving the fruits' natural color, flavor, and texture. |

3. Preservation of Nutritional Value:Unlike conventional sterilization methods, microwave sterilization preserves the nutritional content of preserved fruits by minimizing heat exposure and retaining vitamins, antioxidants, and other essential nutrients. |

4. Reduced Energy Consumption:Microwave sterilization machines are energy-efficient, consuming less energy compared to traditional sterilization methods such as steam or hot water, leading to cost savings for manufacturers. |

5. Enhanced Food Safety:Microwave sterilization effectively eliminates harmful bacteria, molds, and pathogens from preserved fruits, ensuring food safety and extending shelf life without the need for chemical preservatives. |

6. Environmentally Friendly:By reducing energy consumption and eliminating the need for chemical preservatives, microwave sterilization contributes to environmental sustainability and promotes eco-friendly food processing practices. |

7. Flexibility and Versatility:Microwave sterilization machines can accommodate a wide range of preserved fruits in various forms, including slices, chunks, or purees, offering flexibility and versatility in processing different fruit products. |

8. Minimal Processing Losses:With precise control over sterilization parameters, microwave sterilization minimizes processing losses by preventing overcooking or degradation of preserved fruits, resulting in higher product yields and profitability. |

9. Compliance with Regulatory Standards:Microwave sterilization technology meets stringent regulatory standards for food safety and quality, ensuring that preserved fruit products meet or exceed industry regulations and consumer expectations. |

10. Improved Storage and Distribution:Preserved fruits sterilized with microwave technology have extended shelf life and enhanced stability, allowing for easier storage, distribution, and transportation, both domestically and internationally. |

Key components of microwave sterilizer for preserved fruits

Component | Description |

Microwave Chamber | The enclosed space where the preserved fruits are placed for sterilization. |

Microwave Generator | Produces microwave energy that is directed into the chamber to heat and sterilize the fruits. |

Control Panel | Interface for setting sterilization parameters such as time, temperature, and power level. |

Temperature Sensor | Monitors the temperature inside the chamber to ensure proper sterilization conditions are met. |

Humidity Control System | Regulates the humidity level within the chamber to optimize the sterilization process. |

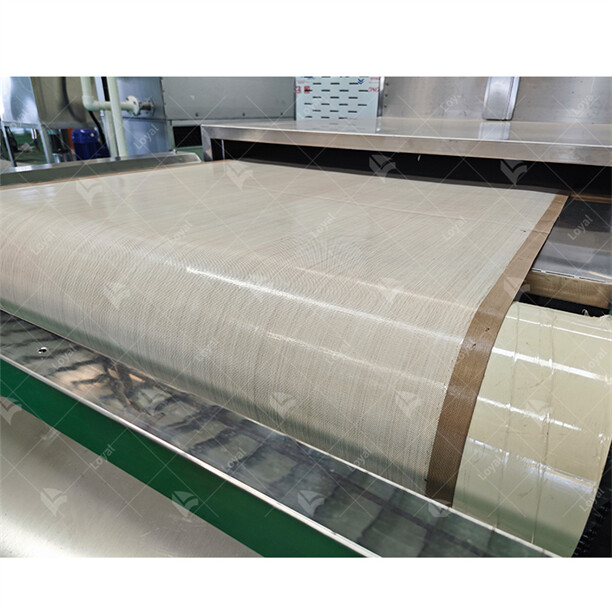

Conveyor System | Moves the preserved fruits through the sterilization process at a controlled pace. |

Safety Interlocks | Mechanisms that prevent the chamber from opening while in operation to ensure user safety. |

Cooling System | Cools down the sterilized fruits after the process to prevent overheating and ensure product safety. |

Comparison and advantages of microwave technology and traditional sterilization methods

Aspect | Microwave Sterilization | Traditional Sterilization |

Speed | Rapid process, typically requires shorter sterilization time | Longer processing time, may take hours or even days to achieve sterilization |

Energy Efficiency | Energy-efficient, as microwaves directly target the product | May require higher energy consumption, as heat is applied externally |

Preservation of Nutrients | Preserves more nutrients due to shorter exposure to heat | May lead to nutrient loss due to prolonged exposure to high temperatures |

Uniformity of Sterilization | Provides more uniform sterilization, reaching all parts of the product | May result in uneven sterilization, with certain parts being under-processed |

Preservation of Flavor | Helps retain natural flavor and aroma of the fruit | May lead to flavor degradation or alteration due to prolonged heat exposure |

Safety | Ensures microbiological safety with efficient sterilization | May pose a higher risk of microbial contamination if sterilization is not thorough |

Shelf Life Extension | Extends shelf life effectively, maintaining product quality for longer | May have a shorter shelf life due to potential nutrient loss and flavor changes |

Types of microwave sterilizer for preserved fruits

Types of microwave sterilizers for preserved fruits vary based on their design, capacity, and functionality. In 2024, several types of microwave sterilization machines are commonly used in the food industry to ensure the safety and quality of preserved fruits.

1. Batch Microwave Sterilizers:

Batch microwave sterilizers are designed to process a limited quantity of preserved fruits in each batch. They typically consist of a chamber where the preserved fruits are placed for sterilization. These machines use microwave technology to generate heat, effectively killing harmful microorganisms while preserving the flavor and texture of the fruits.

2. Continuous Microwave Sterilization Systems:

Continuous microwave sterilization systems are designed for high-volume production of preserved fruits. They feature a conveyor belt or other continuous feeding mechanism that allows a constant flow of fruits through the sterilization chamber. This continuous process ensures efficient sterilization while maximizing productivity.

3. Vacuum Microwave Sterilizers:

Vacuum microwave sterilizers are equipped with a vacuum chamber that removes air from the sterilization environment. This creates a low-pressure atmosphere, which allows for more effective heat transfer and faster sterilization of preserved fruits. Vacuum sterilization also helps preserve the color, flavor, and nutritional content of the fruits.

4. Multi-Stage Microwave Sterilization Systems:

Multi-stage microwave sterilization systems are designed to provide multiple levels of sterilization to ensure the complete elimination of microorganisms. These systems may include pre-heating stages to raise the temperature of the fruits gradually, followed by exposure to intense microwave radiation for sterilization. The multi-stage approach helps achieve thorough sterilization while minimizing the risk of over-processing.

5. Customized Microwave Sterilization Equipment:

Some manufacturers offer customized microwave sterilization equipment tailored to the specific requirements of preserved fruit processing. These customized solutions may incorporate advanced features such as adjustable power levels, variable conveyor speeds, and precise temperature control to optimize the sterilization process for different types of fruits and production volumes.

Technical parameters

| Technical Parameters Of Continuous Microwave Dryer Industrial Microwave Drying Machine | |||||

| Model | Size LWH(Can be customized according to the customer's requirements) | Output power | Dewaterability | Sterilization capacity | Baking and Roasting capacity (Depends on different raw material) |

| LY-10KW | 5000mm825mm1750mm | ≥10KW | 10KG/Hour | 100KG/Hour | 30-50KG/Hour |

| LY-20KW | 8000mm825mm1750mm | ≥20KW | 20KG/Hour | 200KG/Hour | 60-100KG/Hour |

| LY-30KW | 8500mm1160mm1750mm | ≥30KW | 30KG/Hour | 300KG/Hour | 90-150 KG/Hour |

| LY-40KW | 10000mm1160mm1750mm | ≥40KW | 40KG/Hour | 40KG/Hour | 120-200KG/Hour |

| LY-50KW | 12500mm1160mm1750mm | ≥50KW | 50KG/Hour | 500KG/Hour | 150-250KG/Hour |

| LY-60KW | 13500mm1450mm1750mm | ≥60KW | 60KG/Hour | 600KG/Hour | 180-300KG/Hour |

| LY-70KW | 13500mm1500mm1750mm | ≥70KW | 70KG/Hour | 700KG/Hour | 210-350KG/Hour |

| LY-80KW | 13500mm1650mm1750mm | ≥80KW | 80KG/Hour | 800KG/Hour | 240-400KG/Hour |

| LY-100KW | 16800mm1650mm1750mm | ≥100KW | 100KG/Hour | 1000KG/Hour | 300-500KG/Hour |

| LY-150KW | 22400mm1850mm1750mm | ≥150KW | 150KG/Hour | 1500KG/Hour | 450-750KG/Hour |

| LY-200KW | 27000mm1850mm1750mm | ≥250KW | 250KG/Hour | 2500KG/Hour | 750-1250/Hour |

| LY-300KW | 32000mm1850mm1750mm | ≥300KW | 300KG/Hour | 3000KG/Hour | 900-1500KG/Hour |

| Power Supply | 380V±10% 50Hz±1% Three-Phase Five-Wire | ||||

| Microwave Output Frequency | 2450±50Mhz | ||||

| Microwave Input Apparent Power | ≤168Kva | ||||

| Microwave Output Power | ≥120Kw | ||||

| Microwave Power Adjustment Range | 0-30Kw(Adjustable) | ||||

| Ambient Temperature | -5-40°C | ||||

| Relative Humidity | ≤80%, Surrounding Environment:No Corrosive Gas, Conductive Dust And Explosive Gas | ||||

| Transmission Speed | 0-10m/Min(Adjustable) | ||||

Technological progress and innovation of microwave sterilizer for preserved fruits

In 2024, the technological progress and innovation of microwave sterilizers for preserved fruits have reached unprecedented levels. These advanced machines play a crucial role in ensuring the safety and quality of preserved fruits by effectively eliminating harmful microorganisms while preserving their taste, texture, and nutritional value.

Advanced Microwave Technology:

The latest microwave sterilizers for preserved fruits leverage cutting-edge technology to achieve optimal results. These machines utilize precise microwave radiation to penetrate the fruits and eliminate bacteria, molds, and yeast, ensuring thorough sterilization without compromising the fruit's integrity.

Innovative Design Features:

Manufacturers have introduced innovative design features to enhance the efficiency and effectiveness of microwave sterilizers for preserved fruits. These features may include advanced control systems for precise temperature and humidity regulation, customizable sterilization cycles to accommodate different types of fruits, and automated processes for increased productivity.

Improved Safety Measures:

In response to stringent safety standards and regulations, microwave sterilizers for preserved fruits incorporate enhanced safety measures. These measures may include built-in sensors and monitoring systems to detect and prevent overheating, as well as fail-safe mechanisms to ensure safe operation and prevent accidents.

Energy Efficiency and Sustainability:

With a growing emphasis on sustainability, modern microwave sterilizers for preserved fruits are designed to be energy-efficient and environmentally friendly. These machines optimize energy consumption and minimize waste generation, contributing to a more sustainable food processing industry.

Future Outlook:

Looking ahead, the future of microwave sterilizers for preserved fruits is promising. Continued research and development efforts are expected to lead to further advancements in technology, resulting in even more efficient and versatile machines. These advancements will enable manufacturers to meet the evolving needs of the food industry while maintaining high standards of safety and quality for preserved fruits.

Challenges and limitations of microwave sterilizer for preserved fruits

When considering the utilization of microwave sterilization machines for preserved fruits in 2024, several challenges and limitations arise that must be addressed to ensure optimal performance and safety standards.

1. Uniformity of Sterilization:

One of the primary challenges faced by microwave sterilization machines is achieving uniform sterilization across all preserved fruits. Microwave radiation may not penetrate certain fruits evenly, leading to uneven sterilization and potential safety hazards.

2. Moisture Content Variation:

Preserved fruits often have varying moisture contents, which can affect the efficiency of microwave sterilization. Fruits with higher moisture content may absorb more microwave energy, leading to over-sterilization, while fruits with lower moisture content may not be adequately sterilized.

3. Heat Sensitivity of Fruits:

Certain preserved fruits are sensitive to heat and may undergo undesirable changes in texture, flavor, and nutritional content when exposed to microwave radiation for sterilization. Maintaining the delicate balance between sterilization and preserving fruit quality presents a significant challenge.

4. Packaging Constraints:

The packaging materials used for preserved fruits must be microwave-safe to prevent the risk of contamination or damage during sterilization. However, finding suitable packaging materials that meet both safety and efficiency requirements can be challenging.

5. Regulatory Compliance:

Microwave sterilization processes for preserved fruits must comply with stringent regulatory standards to ensure food safety and consumer protection. Meeting these regulatory requirements while maintaining cost-effectiveness and efficiency poses a significant challenge for manufacturers.

6. Equipment Maintenance:

Regular maintenance and calibration of microwave sterilization machines are essential to ensure consistent performance and compliance with safety standards. However, maintaining and servicing complex machinery can be time-consuming and resource-intensive.

Post-maintenance of microwave sterilizer for preserved fruits

Post-maintenance of microwave sterilizer for preserved fruits involves essential procedures to ensure the optimal performance and longevity of the machine. After extensive use, it's crucial to conduct regular maintenance to uphold food safety standards and preserve the quality of preserved fruits.

Cleaning and Sanitization:

First and foremost, thoroughly clean and sanitize all components of the microwave sterilizer. This includes the chamber, conveyor belts, trays, and any other surfaces that come into contact with the preserved fruits. Use approved cleaning agents and follow manufacturer guidelines to eliminate any traces of contaminants and bacteria.

Inspection of Components:

Inspect all components of the microwave sterilizer for signs of wear and tear. Pay close attention to seals, gaskets, and electrical connections, ensuring they are intact and functioning properly. Replace any damaged or worn-out parts to prevent leakage or malfunction during operation.

Calibration and Adjustment:

Calibrate the microwave sterilizer according to manufacturer specifications. This involves adjusting power levels, temperature settings, and conveyor speed to ensure consistent and effective sterilization of preserved fruits. Use calibrated instruments and follow standard procedures to achieve accurate results.

Testing and Validation:

Conduct testing and validation procedures to verify the performance of the microwave sterilizer. Run test cycles with controlled parameters and monitor the sterilization process closely. Validate the effectiveness of the sterilization by testing samples of preserved fruits for microbial load and quality attributes.

Documentation and Record-Keeping:

Maintain detailed records of all maintenance activities and testing results. Document cleaning schedules, component inspections, calibration adjustments, and validation tests. Keep comprehensive records to demonstrate compliance with food safety regulations and quality assurance standards.

Training and Education:

Provide training for operators and maintenance personnel on proper post-maintenance procedures. Ensure that staff members are familiar with the operation of the microwave sterilizer and understand their responsibilities in maintaining its functionality and cleanliness. Continuous education and training are essential for upholding food safety standards and optimizing machine performance.

References

The following are five authoritative foreign literature websites in the field of industrial microwaves:

1. IEEE Xplore Digital Library

Website: [https://ieeexplore.ieee.org/]

2.ScienceDirect

Website: [https://www.sciencedirect.com/]

3. SpringerLink

Website: [https://link.springer.com/]

4. Wiley Online Library

Website: [https://onlinelibrary.wiley.com/]

5. PubMed

Website: [https://pubmed.ncbi.nlm.nih.gov/]

Telephone :+86-531-55583139

Telephone :+86-531-55583139 WhatsApp :+86 13256674591

WhatsApp :+86 13256674591 Email :

Email :