Everything you Need to Know About Microwave Turmeric Powder Drying Machine

Introduction to Microwave Turmeric Powder Drying Machines

Microwave turmeric powder drying machines are innovative industrial equipment designed to efficiently dry turmeric powder using microwave technology. These machines play a crucial role in the food processing industry, particularly in the production of spices and seasonings. Let's delve into the details of how these machines work and their significance in the food manufacturing process.

Microwave turmeric powder drying machines utilize electromagnetic waves to generate heat within the turmeric powder, effectively removing moisture and preserving the quality of the product. This process offers several advantages over traditional drying methods, including faster drying times, higher energy efficiency, and better retention of flavor and nutrients.

History and Development of Microwave Drying Technology

The history of microwave drying technology dates back to the early 20th century when researchers first discovered the potential of microwave radiation for heating and drying purposes. However, it wasn't until the mid-20th century that microwave technology began to be applied on an industrial scale.

The development of microwave drying technology accelerated in the latter half of the 20th century, driven by advancements in electronics, materials science, and food processing. Researchers and engineers experimented with different microwave frequencies, power levels, and processing techniques to optimize the drying process for various food products, including spices like turmeric.

Today, microwave drying technology has become an integral part of modern food processing operations, offering unmatched precision, efficiency, and quality control. Microwave turmeric powder drying machines represent the culmination of decades of research and innovation, providing food manufacturers with a reliable and cost-effective solution for drying turmeric powder at scale.

Key Components and Functions of Turmeric Powder Drying Machines

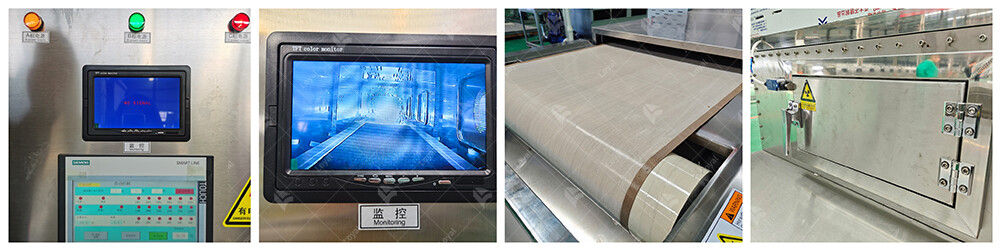

Microwave turmeric powder drying machines are sophisticated pieces of industrial equipment designed to efficiently dry turmeric powder using microwave technology. These machines consist of several key components, each playing a crucial role in the drying process.

First and foremost, the microwave turmeric powder drying machine is equipped with a microwave generator, which produces electromagnetic waves at specific frequencies. These waves penetrate the turmeric powder, causing the water molecules within it to vibrate rapidly, generating heat and facilitating evaporation.

Another essential component is the conveyor belt or tray system, which transports the raw turmeric powder through the drying chamber. The design and material of the conveyor belt are carefully selected to ensure optimal heat distribution and airflow, thereby maximizing drying efficiency.

Additionally, microwave turmeric powder drying machines are equipped with sensors and control systems that monitor various parameters such as temperature, humidity, and moisture content. These systems enable operators to fine-tune the drying process for optimal results and prevent overheating or under-drying of the turmeric powder.

Ventilation and exhaust systems are integrated into the machine to remove excess moisture and maintain a controlled drying environment. Proper ventilation is essential to prevent condensation and ensure uniform drying throughout the batch of turmeric powder.

Understanding the Drying Process: From Raw Turmeric to Dried Powder

The drying process is a critical stage in the production of turmeric powder, as it removes moisture and preserves the flavor, color, and nutritional properties of the spice. Understanding this process, from raw turmeric to dried powder, sheds light on the importance of using advanced drying technology such as microwave turmeric powder drying machines.

It all begins with the selection and harvesting of fresh turmeric rhizomes, which are washed, peeled, and sliced into uniform pieces. These raw turmeric slices are then loaded onto the conveyor belt of the drying machine, where they undergo the drying process.

As the raw turmeric slices pass through the drying chamber, they are exposed to microwave radiation emitted by the microwave generator. The electromagnetic waves penetrate the turmeric slices, causing the water molecules within them to oscillate and generate heat. This heat accelerates the evaporation of moisture, gradually reducing the moisture content of the turmeric slices.

Over time, the raw turmeric slices transform into dried slices, characterized by their reduced moisture content and intensified flavor and aroma. Once the desired moisture level is reached, the dried turmeric slices are ground into a fine powder, ready for packaging and distribution.

Advantages of Microwave Technology in Turmeric Powder Drying

Microwave technology offers several distinct advantages over traditional drying methods when it comes to processing turmeric powder. First and foremost, microwave turmeric powder drying machines utilize electromagnetic waves to generate heat directly within the material. This results in a faster drying process compared to conventional methods such as air or oven drying.

Furthermore, microwave drying is highly efficient, allowing for uniform heating throughout the material. This helps to preserve the quality and integrity of the turmeric powder, ensuring that it retains its color, flavor, and nutritional properties. Unlike conventional drying methods, which can lead to uneven drying and loss of essential oils and nutrients, microwave technology offers precise control over the drying process, minimizing these undesirable effects.

In addition to efficiency and quality preservation, microwave turmeric powder drying machines are also highly versatile. They can accommodate a wide range of batch sizes and drying requirements, making them suitable for both small-scale and large-scale production operations. This flexibility allows manufacturers to adapt to changing market demands and optimize their production processes accordingly.

Overall, the use of microwave technology in turmeric powder drying offers significant benefits in terms of efficiency, quality, and versatility. By harnessing the power of electromagnetic waves, these machines enable faster drying times, uniform heating, and precise control over the drying process, ultimately resulting in high-quality turmeric powder products that meet consumer expectations.

Quality Control and Safety Measures in Drying Operations

Ensuring quality control and implementing safety measures are essential aspects of turmeric powder drying operations, especially when utilizing microwave technology. One of the key quality control measures is to maintain strict adherence to standardized drying parameters, including temperature, humidity, and drying time. This helps to ensure consistent product quality and minimize variations between batches.

Additionally, regular monitoring and testing of the dried turmeric powder are necessary to verify its quality and compliance with regulatory standards. This may involve conducting moisture content analysis, microbial testing, and sensory evaluation to assess the product's overall quality and safety.

In terms of safety measures, it is essential to implement proper equipment maintenance protocols to prevent malfunctions or breakdowns that could compromise the safety of the drying process. This includes regular cleaning, inspection, and calibration of microwave turmeric powder drying machines to ensure optimal performance and minimize the risk of contamination or cross-contamination.

Furthermore, proper handling and storage practices should be observed to prevent contamination and ensure product safety. This includes maintaining proper hygiene standards in the drying facility, implementing appropriate sanitation procedures, and storing the dried turmeric powder in clean, dry containers to prevent moisture absorption and microbial growth.

Innovations in Microwave Turmeric Powder Drying Machines

In recent years, there have been notable innovations in microwave turmeric powder drying machines, revolutionizing the way turmeric is processed and preserved. These innovations aim to enhance efficiency, improve product quality, and minimize energy consumption.

One significant innovation in microwave turmeric powder drying machines is the integration of advanced control systems. These systems allow for precise regulation of temperature, humidity, and airflow, ensuring optimal drying conditions for turmeric. By maintaining consistent parameters throughout the drying process, manufacturers can achieve higher yields and superior product quality.

Another innovation is the development of multi-stage drying systems. Unlike traditional single-stage drying processes, multi-stage systems allow for more thorough drying of turmeric powder while minimizing the risk of over-drying or uneven moisture content. By dividing the drying process into multiple stages, manufacturers can achieve greater control over the final product's quality and consistency.

Furthermore, advancements in material handling technology have contributed to increased automation and efficiency in microwave turmeric powder drying machines. Automated loading and unloading systems, as well as conveyor belts with adjustable speed and direction, streamline the production process and reduce labor costs. Additionally, improved sealing mechanisms and insulation materials help minimize heat loss and energy wastage, further enhancing the machines' efficiency.

Comparing Different Models of Microwave Drying Equipment

When comparing different models of microwave drying equipment for turmeric powder, it's essential to consider various factors, including performance, reliability, efficiency, and cost. Two prominent manufacturers in this field are LOYAL and FEN, each offering their own unique machines tailored to meet specific industry needs.

Feature | LOYAL Microwave Drying Machine | FEN Microwave Drying Machine |

Capacity | High | Moderate |

Drying Efficiency | Superior | Good |

Control Systems | Advanced | Standard |

Automation | High | Moderate |

Energy Consumption | Low | Moderate |

Maintenance | Easy | Moderate |

Cost | Higher | Lower |

LOYAL's microwave drying machine boasts high capacity, superior drying efficiency, and advanced control systems, making it an ideal choice for large-scale operations requiring precise control over the drying process. However, its higher initial cost may be a deterrent for smaller businesses.

On the other hand, FEN's microwave drying machine offers good performance at a lower cost, making it a more budget-friendly option for smaller-scale operations with less stringent requirements. While it may not have all the advanced features of LOYAL's machine, it still provides reliable drying capabilities at a more affordable price point.

Ultimately, the choice between LOYAL and FEN microwave drying machines depends on the specific needs and priorities of each individual manufacturer, weighing factors such as capacity, performance, automation, and budget.

Maintenance and Troubleshooting Tips for Optimal Machine Performance

Maintaining a microwave turmeric powder drying machine is crucial for ensuring consistent performance and extending its lifespan. Here are some essential maintenance and troubleshooting tips to keep your machine running smoothly:

1. Regular Cleaning and Inspection: To prevent the buildup of residue and ensure hygiene, clean the machine's interior, conveyor belts, and other components regularly. Inspect for any signs of wear or damage, such as loose belts or frayed wiring, and address them promptly to avoid potential breakdowns.

2. Lubrication of Moving Parts: Proper lubrication of bearings, rollers, and other moving parts is essential for reducing friction and preventing premature wear. Use lubricants recommended by the manufacturer and adhere to the specified maintenance schedule to keep the machine operating smoothly.

3. Calibration and Adjustment: Periodically calibrate the machine's temperature and humidity controls to ensure accurate drying conditions. Additionally, check and adjust any settings related to airflow, conveyor speed, and power output to optimize drying efficiency and quality.

4. Monitoring Performance Metrics: Regularly monitor key performance metrics, such as drying time, energy consumption, and product moisture content, to identify any deviations from the norm. Keep detailed records of these metrics and use them to track the machine's performance over time and detect any potential issues early on.

Troubleshooting Tips

1. Inconsistent Drying Results: If you notice variations in the drying results, such as uneven moisture content or coloration, check for obstructions in the airflow path, uneven distribution of turmeric powder on the conveyor, or malfunctioning heating elements. Adjust the settings accordingly and conduct a test run to verify the effectiveness of the adjustments.

2. Excessive Noise or Vibrations: Unusual noises or vibrations may indicate loose components, worn bearings, or imbalanced loads. Inspect the machine for any loose fasteners or damaged parts and tighten or replace them as needed. Balancing the load on the conveyor can also help reduce vibrations and noise.

3. Electrical Issues: If the machine experiences power fluctuations or electrical malfunctions, check the power supply, circuit breakers, and wiring connections for any signs of damage or corrosion. Consult with a qualified electrician to diagnose and repair any electrical issues to ensure safety and prevent further damage to the machine.

4. Safety Precautions: Always follow the manufacturer's safety guidelines and protocols when performing maintenance or troubleshooting tasks. Disconnect the machine from the power source before conducting any inspections or repairs and wear appropriate personal protective equipment to prevent accidents or injuries.

Case Studies: Success Stories of Using Microwave Turmeric Powder Drying Machines

Several companies have successfully implemented microwave turmeric powder drying machines in their production processes, achieving significant improvements in efficiency, product quality, and cost savings.

1. Company LOYAL, a spice manufacturer, replaced their conventional drying equipment with a state-of-the-art microwave turmeric powder drying machine. As a result, they were able to reduce drying times by 50% while maintaining consistent moisture levels and preserving the natural color and flavor of the turmeric powder. This efficiency gain allowed them to increase their production capacity and meet growing customer demand without compromising quality.

2. Company FEN, a food processing company, faced challenges with conventional drying methods, which often resulted in inconsistent drying and product degradation. After adopting a microwave turmeric powder drying machine, they experienced a significant improvement in product quality and shelf life. The precise control offered by the machine allowed them to achieve uniform drying across batches, resulting in a more visually appealing and flavorful product that garnered positive feedback from customers.

These case studies highlight the tangible benefits of using microwave turmeric powder drying machines in industrial settings, including improved efficiency, product quality, and customer satisfaction. By investing in advanced drying technology, companies can enhance their competitiveness and drive growth in the highly competitive food processing industry.

References

1.Tetra Pak : https://www.tetrapak.com

2.Jinan Kelid Machinery Co., Ltd.: http://www.kldfoodmachine.com

3. GEA : https://www.gea.com

4. MAX Industrial Microwave: https://www.maxindustrialmicrowave.com

5. Marel: https://marel.com

Telephone :+86-531-55583139

Telephone :+86-531-55583139 WhatsApp :+86 13256674591

WhatsApp :+86 13256674591 Email :

Email :