Everything you need to know about Microwave Spirulina Drying Sterilization Machine in 2024

Introduction

In 2024, the landscape of food processing is witnessing a significant transformation with the advent of advanced technologies. Among these, the microwave spirulina drying sterilization machine emerges as a pivotal innovation, revolutionizing the production of spirulina-based products.

In this comprehensive guide, we delve into everything you need to know about the microwave spirulina drying sterilization machine, exploring its key features, operational functionalities, benefits, and applications. Join us as we unravel the intricacies of this groundbreaking technology and its impact on the spirulina processing industry in 2024.

Key Features and Components

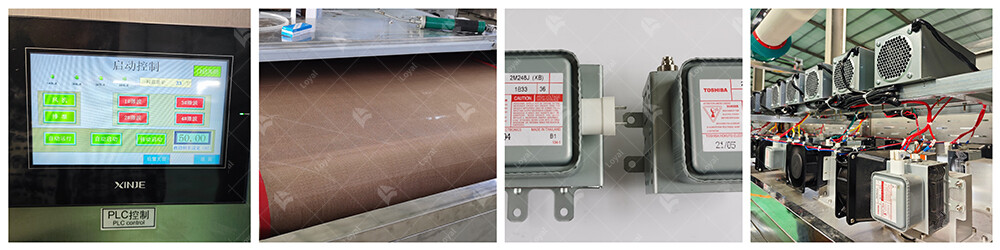

Microwave Technology Integration

The microwave spirulina drying sterilization machine utilizes advanced microwave technology to efficiently dry and sterilize spirulina. This technology offers rapid heating and moisture removal, significantly reducing processing time compared to conventional methods. The microwave energy penetrates deep into the spirulina, ensuring uniform drying and effective sterilization.

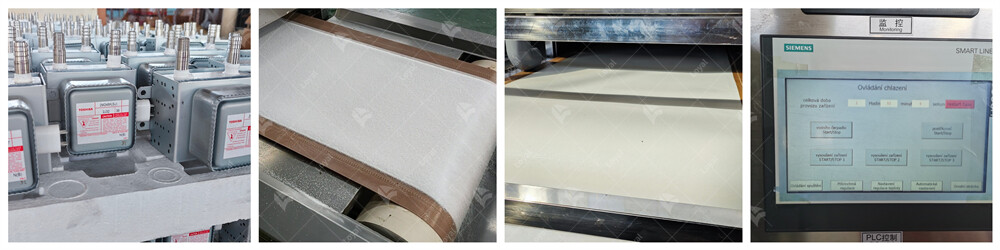

Structure and Design

The machine features a robust and hygienic stainless steel construction, designed to meet stringent food safety standards. It comprises a tunnel structure where spirulina is transported on a continuous belt, allowing for seamless processing. The design ensures easy access for cleaning and maintenance, enhancing the machine's operational efficiency.

Temperature and Humidity Control

Precise temperature and humidity control is critical in the microwave spirulina drying sterilization machine. The system is equipped with advanced sensors and controllers that monitor and adjust these parameters in real-time. This ensures optimal drying conditions, preserving the nutritional quality of the spirulina while achieving thorough sterilization.

Belt Mechanism

The continuous belt mechanism is a key component of the machine, providing a steady and controlled flow of spirulina through the drying and sterilization process. The belt is made of food-grade materials that are resistant to heat and wear, ensuring durability and safety. The speed of the belt can be adjusted to match the specific processing requirements.

Control Systems

Modern microwave spirulina drying sterilization machines are equipped with sophisticated PLC (Programmable Logic Controller) and HMI (Human-Machine Interface) systems. These control systems allow for precise operation and monitoring of the entire process, offering user-friendly interfaces for operators to adjust settings and monitor performance.

Energy Efficiency

Energy efficiency is a significant advantage of the microwave spirulina drying sterilization machine. The microwave technology ensures minimal energy loss, making the process cost-effective and environmentally friendly. Innovations in the machine's design also contribute to reduced energy consumption while maintaining high processing standards.

Safety Features

Safety is paramount in the design of the microwave spirulina drying sterilization machine. The machine includes multiple safety features such as emergency stop buttons, overheating protection, and interlock systems that prevent operation if the machine is not properly secured. These features ensure the safety of both the operators and the product.

Operation and Functionality

Process Workflow

The microwave spirulina drying sterilization machine is designed to streamline the processing of spirulina from its raw form to a dried, sterilized product ready for consumption. The process begins by feeding raw spirulina into the machine, where it is evenly distributed on a conveyor belt. The spirulina then passes through the microwave drying chamber, where microwave energy rapidly removes moisture while maintaining the nutritional integrity of the spirulina. Finally, the product is sterilized to eliminate any microbial contamination before it exits the machine, ensuring a high-quality, safe product.

Microwave Technology Integration

Microwave technology is at the core of this machine's operation. By using microwave energy, the machine can achieve rapid and uniform drying and sterilization. The microwaves penetrate the spirulina, causing water molecules to vibrate and heat up, which accelerates the drying process. Simultaneously, the high temperatures generated by the microwaves effectively sterilize the spirulina, killing any harmful bacteria or pathogens.

Temperature and Humidity Control

Maintaining precise control over temperature and humidity is crucial in the drying and sterilization process. The microwave spirulina drying sterilization machine is equipped with advanced sensors and control systems that monitor and adjust these parameters in real-time. This ensures that the spirulina is dried evenly and sterilized thoroughly, preventing over-drying or under-drying, which can affect the quality and shelf life of the final product.

Automation and Control Systems

The machine features a high level of automation, which enhances its efficiency and ease of use. Programmable Logic Controllers (PLCs) and Human-Machine Interfaces (HMIs) allow operators to set and monitor processing parameters with precision. Automation reduces the need for manual intervention, minimizes human error, and ensures consistent product quality.

Energy Efficiency

Energy efficiency is a significant advantage of the microwave spirulina drying sterilization machine. Microwave drying is faster than conventional drying methods, leading to reduced energy consumption. The machine's design includes energy-saving features that optimize microwave energy use, contributing to lower operational costs and a smaller environmental footprint.

Benefits and Applications

Aspect | Description |

Quality and Safety Assurance | The microwave spirulina drying sterilization machine ensures high safety and hygiene by effectively eliminating pathogens and contaminants. It meets stringent regulatory standards. |

Nutritional Preservation | Microwave technology preserves the nutritional content of spirulina, maintaining its beneficial compounds, vitamins, and minerals. |

Enhanced Shelf Life | The machine significantly extends the shelf life of spirulina products by reducing moisture content and preventing microbial growth. |

Efficiency and Speed | Microwave drying and sterilization are faster than traditional methods, increasing production efficiency and reducing processing time. |

Energy Efficiency | Modern microwave spirulina drying sterilization machines are designed to be energy-efficient, reducing operational costs and environmental impact. |

Consistency and Uniformity | The machine ensures uniform drying and sterilization, resulting in consistent product quality and texture. |

Versatility | Suitable for various forms of spirulina (powder, flakes, etc.), making it adaptable for different product requirements. |

Scalability | The machine can be scaled to meet different production capacities, from small-scale operations to large industrial setups. |

Automation and Control | Equipped with advanced PLC and HMI systems for automated control, ensuring precision and reducing human error. |

Market Demand | Addresses the growing market demand for high-quality spirulina products, driven by increasing consumer awareness of its health benefits. |

Technical specifications

| Technical Parameters Of Continuous Microwave Dryer Industrial Microwave Drying Machine | |||||

| Model | Size LWH(Can be customized according to the customer's requirements) | Output power | Dewaterability | Sterilization capacity | Baking and Roasting capacity (Depends on different raw material) |

| LY-10KW | 5000mm825mm1750mm | ≥10KW | 10KG/Hour | 100KG/Hour | 30-50KG/Hour |

| LY-20KW | 8000mm825mm1750mm | ≥20KW | 20KG/Hour | 200KG/Hour | 60-100KG/Hour |

| LY-30KW | 8500mm1160mm1750mm | ≥30KW | 30KG/Hour | 300KG/Hour | 90-150 KG/Hour |

| LY-40KW | 10000mm1160mm1750mm | ≥40KW | 40KG/Hour | 40KG/Hour | 120-200KG/Hour |

| LY-50KW | 12500mm1160mm1750mm | ≥50KW | 50KG/Hour | 500KG/Hour | 150-250KG/Hour |

| LY-60KW | 13500mm1450mm1750mm | ≥60KW | 60KG/Hour | 600KG/Hour | 180-300KG/Hour |

| LY-70KW | 13500mm1500mm1750mm | ≥70KW | 70KG/Hour | 700KG/Hour | 210-350KG/Hour |

| LY-80KW | 13500mm1650mm1750mm | ≥80KW | 80KG/Hour | 800KG/Hour | 240-400KG/Hour |

| LY-100KW | 16800mm1650mm1750mm | ≥100KW | 100KG/Hour | 1000KG/Hour | 300-500KG/Hour |

| LY-150KW | 22400mm1850mm1750mm | ≥150KW | 150KG/Hour | 1500KG/Hour | 450-750KG/Hour |

| LY-200KW | 27000mm1850mm1750mm | ≥250KW | 250KG/Hour | 2500KG/Hour | 750-1250/Hour |

| LY-300KW | 32000mm1850mm1750mm | ≥300KW | 300KG/Hour | 3000KG/Hour | 900-1500KG/Hour |

| Power Supply | 380V±10% 50Hz±1% Three-Phase Five-Wire | ||||

| Microwave Output Frequency | 2450±50Mhz | ||||

| Microwave Input Apparent Power | ≤168Kva | ||||

| Microwave Output Power | ≥120Kw | ||||

| Microwave Power Adjustment Range | 0-30Kw(Adjustable) | ||||

| Ambient Temperature | -5-40°C | ||||

| Relative Humidity | ≤80%, Surrounding Environment:No Corrosive Gas, Conductive Dust And Explosive Gas | ||||

| Transmission Speed | 0-10m/Min(Adjustable) | ||||

Installation and Setup

Installing and setting up a microwave spirulina drying sterilization machine is a crucial step to ensure optimal performance and efficiency in spirulina processing. Here's what you need to know:

1. Site Preparation: Before installation, ensure that the site chosen for placing the machine meets all necessary requirements. This includes sufficient space for the machine and its accessories, adequate ventilation, and access to power sources.

2. Unpacking and Inspection: Upon delivery, carefully unpack the machine and its components. Inspect them thoroughly for any signs of damage or defects. Contact the manufacturer immediately if any issues are detected.

3. Positioning: Choose the optimal location for placing the microwave spirulina drying sterilization machine. Consider factors such as proximity to other equipment, workflow efficiency, and safety regulations. Ensure that the machine is placed on a stable and level surface.

4. Electrical Connection: Connect the machine to a suitable power source according to the manufacturer's specifications. Ensure that the voltage and frequency match the machine's requirements to prevent damage and ensure safe operation.

5. Ventilation: Proper ventilation is essential to prevent overheating and ensure efficient operation of the machine. Install any required ventilation systems or exhaust fans as per the manufacturer's guidelines.

6. Water Connection (if applicable): Some machines may require a water connection for cooling purposes. Ensure that the water supply is connected correctly and that there are no leaks or blockages in the system.

7. Calibration: Once the machine is installed, calibrate it according to the manufacturer's instructions. This may involve adjusting temperature and humidity settings to ensure optimal drying and sterilization conditions.

8. Training: Provide training to operators on how to safely and effectively use the microwave spirulina drying sterilization machine. This includes proper operation procedures, maintenance tasks, and safety precautions.

9. Testing: Before putting the machine into full operation, conduct thorough testing to ensure that all components are functioning correctly. Monitor the drying and sterilization process to verify that it meets the desired standards.

10. Documentation: Keep detailed records of the installation process, including any modifications made and tests conducted. This documentation will be valuable for future reference and troubleshooting.

Technological Innovations and Future Prospects

In 2024, the landscape of microwave spirulina drying sterilization machines is witnessing remarkable technological innovations poised to revolutionize the spirulina processing industry. These advancements are driven by the pursuit of greater efficiency, improved product quality, and enhanced sustainability.

1. Enhanced Microwave Technology Integration

One of the most significant advancements in microwave spirulina drying sterilization machines is the integration of enhanced microwave technology. Manufacturers are incorporating state-of-the-art microwave systems with advanced controls and sensors to precisely regulate drying and sterilization processes. These systems offer higher power output, improved energy efficiency, and enhanced uniformity in drying and sterilizing spirulina, resulting in superior product quality and reduced processing time.

2. Automation and Artificial Intelligence

The future of microwave spirulina drying sterilization machines lies in automation and artificial intelligence (AI). Machine learning algorithms and AI-driven systems are being integrated into these machines to optimize process parameters, predict equipment maintenance needs, and improve overall efficiency. Automated systems enable real-time monitoring and adjustment of drying and sterilization parameters, ensuring consistent product quality while minimizing energy consumption and waste.

3. Sustainability and Eco-Friendly Practices

In response to growing environmental concerns, manufacturers are prioritizing sustainability in the design and operation of microwave spirulina drying sterilization machines. Innovations such as energy-efficient microwave technology, recyclable materials, and water-saving processes are being implemented to reduce the environmental footprint of spirulina processing operations. Additionally, advancements in waste management and byproduct utilization are contributing to a more sustainable and eco-friendly spirulina industry.

4. Integration of Smart Manufacturing Concepts

The concept of smart manufacturing is gaining traction in the spirulina processing industry, leading to the integration of intelligent systems and connectivity solutions in microwave drying sterilization machines. These smart machines leverage data analytics, cloud computing, and Internet of Things (IoT) technology to optimize production processes, improve equipment reliability, and enable predictive maintenance. By harnessing the power of data and connectivity, manufacturers can achieve greater operational efficiency and competitiveness in the market.

5. Future Prospects and Industry Outlook

Looking ahead, the future prospects for microwave spirulina drying sterilization machines are promising. Continued research and development efforts are expected to further enhance machine performance, expand product capabilities, and drive down production costs. Additionally, the growing demand for spirulina-based products, fueled by increasing consumer awareness of its health benefits, will drive the adoption of advanced processing technologies. Overall, microwave spirulina drying sterilization machines are poised to play a crucial role in meeting the rising demand for high-quality spirulina products while promoting sustainability and efficiency in the food processing industry.

Maintenance and Troubleshooting

Issue | Potential Causes | Troubleshooting Steps |

Uneven Drying | 1. Improper distribution of spirulina on the drying tray. | 1. Ensure spirulina is evenly spread out on the tray before starting the drying process. |

2. Malfunctioning microwave power distribution. | 2. Check and recalibrate microwave power distribution system. | |

3. Inadequate ventilation causing uneven heat distribution. | 3. Ensure proper ventilation around the machine to maintain even temperature. | |

Power Fluctuations | 1. Voltage fluctuations in the power supply. | 1. Install voltage stabilizers to regulate power supply. |

2. Overloading of the machine causing power surges. | 2. Avoid overloading the machine and distribute the load evenly. | |

Mechanical Failures | 1. Belt slippage or misalignment. | 1. Check and adjust belt tension. |

2. Motor malfunction. | 2. Inspect and replace malfunctioning motors. | |

Sensor Errors | 1. Misalignment or damage to temperature and humidity sensors. | 1. Calibrate or replace sensors as necessary. |

2. Interference from external sources affecting sensor accuracy. | 2. Shield sensors from external interference sources. | |

Emergency Shutdown | 1. Overheating of the machine. | 1. Immediately turn off the machine and allow it to cool down. |

2. Electrical short circuits. | 2. Cut off power supply and investigate the cause of the short circuit. | |

Safety Inspections | 1. Non-functional emergency stop mechanisms. | 1. Regularly test and maintain emergency stop buttons and switches. |

2. Inadequate machine grounding. | 2. Ensure proper grounding of the machine to prevent electrical hazards. |

References

The following are five authoritative foreign literature websites in the field of industrial microwaves:

1. IEEE Xplore Digital Library

Website: [https://ieeexplore.ieee.org/]

2.ScienceDirect

Website: [https://www.sciencedirect.com/]

3. SpringerLink

Website: [https://link.springer.com/]

4. Wiley Online Library

Website: [https://onlinelibrary.wiley.com/]

5. PubMed

Website: [https://pubmed.ncbi.nlm.nih.gov/]

Telephone :+86-531-55583139

Telephone :+86-531-55583139 WhatsApp :+86 13256674591

WhatsApp :+86 13256674591 Email :

Email :