Everything you Need to Know About Microwave Seafood Baking and Drying Machine

Introduction to Microwave Seafood Processing

Microwave seafood processing involves the utilization of microwave technology for baking and drying seafood products. This innovative method offers numerous benefits over traditional processing techniques.

Microwave Seafood Baking and Drying Machine, as the name suggests, utilizes microwave radiation to heat and dry seafood products efficiently. Unlike conventional methods that rely on convection or conduction heating, microwave technology penetrates the seafood, heating it from the inside out. This results in faster processing times and more uniform heating, preserving the texture and flavor of the seafood.

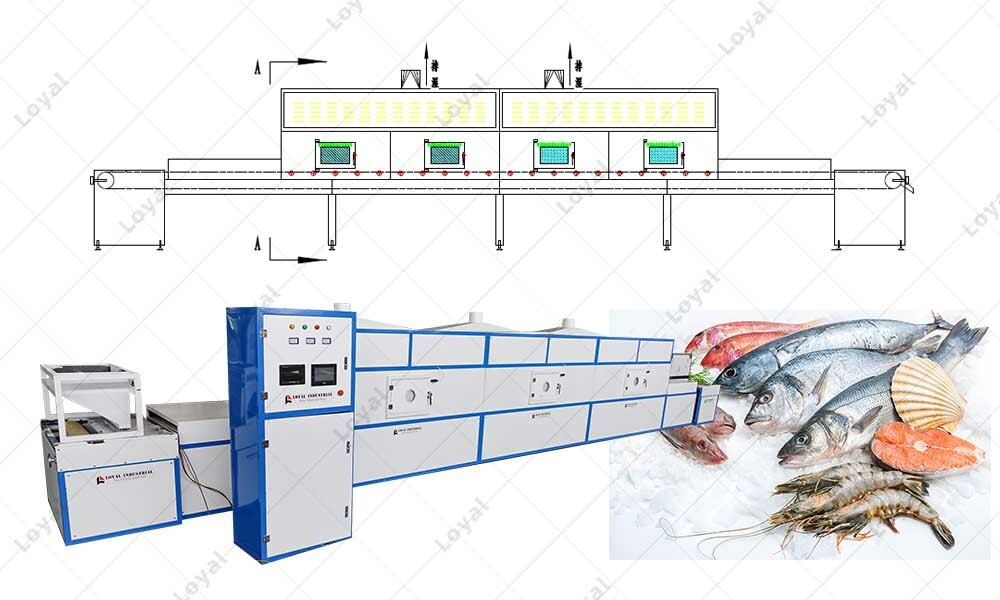

Additionally, microwave seafood processing is highly versatile, accommodating a wide range of seafood products, including fish fillets, shrimp, scallops, and squid. From baking to drying, this technology can be adapted to various processing needs, making it a valuable asset in the food industry.

Moreover, microwave seafood processing offers enhanced control over processing parameters, such as temperature and moisture levels. Operators can adjust these parameters to achieve precise results, ensuring consistent quality and minimizing product waste. Overall, microwave seafood processing represents a modern and efficient approach to seafood processing, revolutionizing the industry with its numerous advantages.

Advantages of Microwave Technology in Seafood Processing

The adoption of microwave technology in seafood processing brings forth several notable advantages, making it a preferred choice for many food manufacturers.

First and foremost, Microwave Seafood Baking and Drying Machines offer rapid processing times compared to conventional methods. The ability of microwaves to penetrate seafood and heat it from within accelerates the baking and drying process, reducing overall processing time and increasing productivity.

Furthermore, microwave technology enables precise control over heating parameters, such as temperature and humidity. This level of control ensures uniform heating throughout the seafood product, minimizing the risk of overcooking or undercooking. As a result, manufacturers can consistently produce high-quality seafood products with optimal texture and flavor.

In addition to efficiency and precision, microwave seafood processing offers energy savings compared to traditional methods. The targeted heating provided by microwave technology reduces the need for preheating and minimizes heat loss, leading to lower energy consumption and operational costs.

Moreover, microwave processing is a clean and environmentally friendly method. It eliminates the need for chemical additives often used in traditional processing, reducing the environmental impact and ensuring food safety and purity.

Overall, the advantages of microwave technology, including rapid processing, precise control, energy efficiency, and environmental friendliness, make it an indispensable tool in seafood processing, driving innovation and quality in the industry.

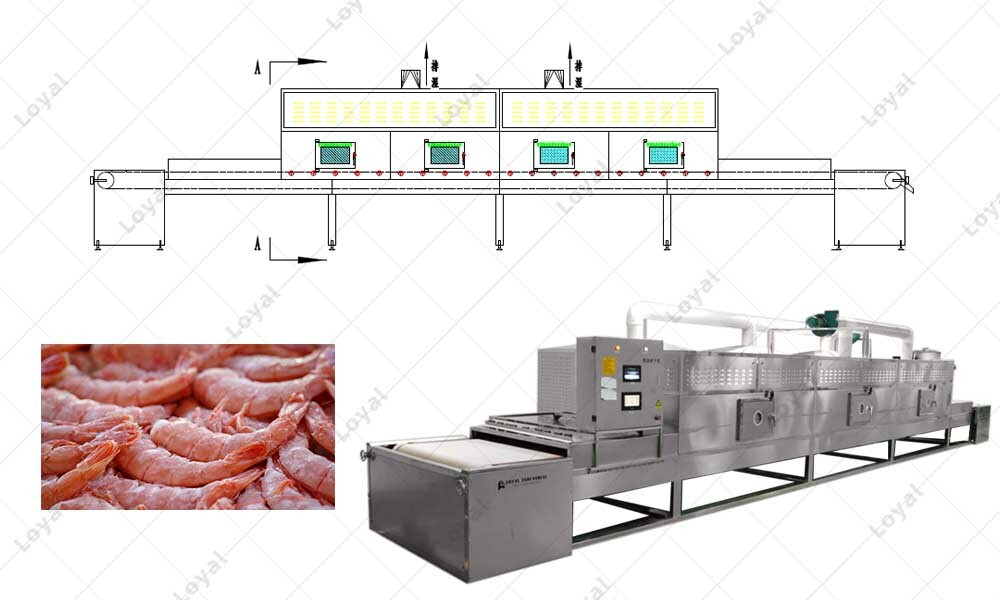

Key Components of Microwave Seafood Baking and Drying Machine

Microwave seafood baking and drying machines are intricate systems comprising several key components essential for their efficient operation and precise control over the baking and drying processes.

One of the primary components of these machines is the magnetron, which generates microwave radiation. The magnetron is the heart of the microwave system, converting electrical energy into electromagnetic waves at the desired frequency. These waves penetrate the seafood, causing water molecules to vibrate and generate heat, facilitating the baking and drying processes.

Another crucial component is the cavity or chamber where the seafood is placed for baking or drying. This cavity is designed to contain and focus microwave radiation onto the seafood evenly. It is typically constructed from stainless steel or other microwave-transparent materials to ensure durability and efficient microwave penetration.

Microwave seafood baking and drying machines feature sophisticated control systems. These systems regulate various parameters such as microwave power, temperature, and moisture levels to achieve the desired baking or drying outcomes. Advanced control algorithms ensure precise adjustment of these parameters, allowing for optimal processing conditions and consistent product quality.

Microwave Radiation and its Effects on Seafood

Microwave radiation plays a fundamental role in seafood processing, particularly in baking and drying applications. Understanding the interaction between microwave radiation and seafood is essential for optimizing processing parameters and ensuring product quality and safety.

When seafood is exposed to microwave radiation, the electromagnetic waves penetrate the food and interact with its molecular structure. Specifically, the water molecules present in seafood absorb microwave energy, causing them to oscillate and generate heat through molecular friction. This rapid internal heating leads to the baking or drying of the seafood, depending on the processing parameters applied.

However, it is essential to recognize that microwave radiation can also have specific effects on seafood quality. Overexposure to microwave radiation can result in uneven heating or localized hot spots, leading to uneven cooking or drying and potential quality defects such as texture changes or flavor alterations.

Microwave radiation can induce chemical and biochemical changes in seafood constituents, potentially affecting nutritional properties or shelf-life characteristics. Careful control of processing parameters, including microwave power levels and exposure times, is crucial to minimize undesirable effects and ensure consistent product quality.

In conclusion, microwave radiation is a powerful tool in seafood processing, driving efficient baking and drying processes. Understanding its effects on seafood quality and implementing appropriate control measures are essential for optimizing processing outcomes and ensuring product safety and consistency.

Operating Principles of Microwave Seafood Baking and Drying Machine

Microwave seafood baking and drying machines operate on the principle of utilizing microwave radiation to efficiently and rapidly heat and dry seafood products. These machines consist of several key components, including a microwave generator, waveguide, cavity, and conveyor system.

The microwave generator produces electromagnetic waves at specific frequencies, typically 2450 MHz for industrial applications, which are then transmitted through the waveguide into the cavity where the seafood products are placed. Once inside the cavity, the microwaves interact with the water molecules present in the seafood.

The interaction between the microwave radiation and water molecules causes them to vibrate rapidly, generating heat throughout the seafood product. This rapid heating process effectively bakes or dries the seafood, depending on the desired outcome. Unlike traditional baking or drying methods, microwave technology heats the seafood uniformly and rapidly, resulting in shorter processing times and improved product quality.

The conveyor system within the machine facilitates the movement of seafood products through the cavity, ensuring even exposure to microwave radiation. By controlling the speed and direction of the conveyor, operators can adjust the processing parameters to achieve the desired level of baking or drying for different types of seafood products.

In summary, the operating principles of microwave seafood baking and drying machines involve the generation of microwave radiation, transmission into the processing cavity, interaction with water molecules in the seafood, and efficient heating or drying through uniform exposure and conveyor movement.

Safety Measures in Microwave Seafood Processing

Safety is paramount in microwave seafood processing to prevent accidents, ensure product quality, and protect the well-being of workers. Several safety measures should be implemented to minimize risks associated with operating microwave seafood baking and drying machines.

Firstly, proper training of personnel is essential to familiarize them with the operation and safety protocols of the equipment. Operators should be educated on the potential hazards of microwave radiation exposure and instructed on how to safely operate the machine, including emergency shutdown procedures.

Additionally, the machine should be equipped with safety interlocks and sensors to detect anomalies such as overheating or malfunctioning components. These safety features can automatically shut down the machine to prevent accidents and mitigate risks to personnel and products.

Furthermore, personal protective equipment (PPE) should be provided to workers, including microwave-safe gloves and aprons, to minimize direct contact with hot surfaces or microwave radiation. Regular maintenance and inspection of the equipment are also essential to identify and address potential safety hazards before they escalate.

Moreover, proper ventilation and exhaust systems should be in place to remove any fumes or odors generated during the baking or drying process. Adequate ventilation not only ensures a safe working environment but also helps maintain product quality by preventing contamination or off-flavors.

Applications of Microwave Seafood Baking and Drying Machine in the Food Industry

Microwave seafood baking and drying machines play a crucial role in the food industry, offering versatile applications across various sectors. These machines utilize microwave radiation to efficiently bake and dry seafood products, providing numerous benefits in terms of speed, quality, and energy efficiency.

One prominent application of microwave seafood baking and drying machines is in seafood processing facilities. These machines are used to bake and dry a wide range of seafood products, including fish fillets, shrimp, scallops, and squid. By utilizing microwave technology, these machines can rapidly and evenly cook seafood, ensuring consistent quality and flavor.

Another important application is in the production of ready-to-eat seafood snacks and meals. Microwave seafood baking and drying machines enable manufacturers to produce convenient, shelf-stable seafood products that require minimal preparation. These products cater to consumer demand for convenient meal options while maintaining the freshness and nutritional value of seafood.

Additionally, microwave seafood baking and drying machines find applications in seafood preservation and packaging. By effectively removing moisture from seafood products, these machines prolong shelf life and prevent spoilage. This is particularly beneficial for seafood exporters, allowing them to transport products over long distances without compromising quality.

Furthermore, microwave seafood baking and drying machines are utilized in research and development laboratories to experiment with new seafood recipes and processing techniques. Their flexibility and precision make them ideal for testing different baking and drying parameters, leading to the innovation of new seafood products and processes.

Quality Control in Microwave Seafood Processing

Ensuring quality control is essential in microwave seafood processing to meet industry standards and consumer expectations for safety and excellence. Microwave seafood baking and drying machines require rigorous quality control measures throughout the production process to maintain product integrity and minimize the risk of contamination or defects.

One crucial aspect of quality control is monitoring and maintaining proper operating parameters of microwave seafood baking and drying machines. This includes regularly calibrating equipment to ensure accurate temperature and moisture control, as well as conducting routine inspections to detect any signs of wear or malfunction.

Additionally, quality control measures involve strict adherence to hygiene and sanitation protocols in seafood processing facilities. Proper cleaning and disinfection of equipment, surfaces, and utensils are essential to prevent cross-contamination and microbial growth, which can compromise product quality and safety.

Furthermore, quality control in microwave seafood processing encompasses thorough inspection and testing of raw materials and finished products. Incoming seafood ingredients should undergo rigorous quality checks to ensure freshness, cleanliness, and compliance with regulatory standards. Likewise, finished seafood products should be inspected for visual defects, texture, flavor, and microbiological safety before distribution.

Moreover, implementing traceability systems is vital for quality control in microwave seafood processing. Traceability allows producers to track the journey of seafood products from the source to the consumer, enabling swift identification and recall of any compromised batches or contaminated products.

Maintenance and Cleaning Procedures for Microwave Equipment

Maintaining and cleaning microwave equipment, particularly microwave seafood baking and drying machines, is crucial for ensuring optimal performance and food safety. Here are the recommended procedures:

1. Regular Inspection and Cleaning: Conduct routine inspections of the microwave seafood baking and drying machine to identify any signs of wear, damage, or contamination. Clean the exterior surfaces with a mild detergent and warm water, followed by thorough rinsing and drying. Pay close attention to areas prone to food buildup, such as seals and vents.

2. Cleaning the Interior: Before cleaning the interior of the machine, ensure it is unplugged and completely cooled down. Remove any removable components, such as trays or racks, and wash them separately using hot, soapy water. Wipe down the interior surfaces with a damp cloth or sponge to remove any food residues or spills. Use a food-safe disinfectant to sanitize the interior, focusing on areas that come into direct contact with seafood.

3. Deodorizing: Over time, microwave equipment may develop odors due to the accumulation of food particles and grease. To eliminate odors, place a microwave-safe bowl filled with water and a few slices of lemon or vinegar inside the machine. Heat the mixture on high for several minutes to create steam, which helps loosen stubborn odors. Wipe down the interior surfaces with a solution of equal parts water and vinegar to neutralize odors effectively.

Regular maintenance and cleaning of microwave equipment are essential for preserving its functionality, extending its lifespan, and ensuring the safety and quality of processed seafood products.

Future Trends and Innovations in Microwave Seafood Processing

The field of microwave seafood processing is continuously evolving, driven by advancements in technology and the demand for more efficient and sustainable food processing methods. Here are some future trends and innovations to watch out for:

1. Precision Control Systems: Future microwave seafood baking and drying machines are likely to incorporate advanced precision control systems, allowing operators to fine-tune parameters such as temperature, humidity, and power levels with greater accuracy. This level of control enables more precise processing tailored to specific seafood products, resulting in improved quality and consistency.

2. Integration of IoT and AI: The integration of Internet of Things (IoT) devices and artificial intelligence (AI) algorithms into microwave seafood processing equipment enables real-time monitoring and optimization of processing parameters. IoT sensors collect data on factors such as moisture content, temperature, and product quality, while AI algorithms analyze this data to adjust processing parameters automatically for optimal results.

3. Energy Efficiency Improvements: Future microwave seafood baking and drying machines will focus on enhancing energy efficiency through innovative heating technologies, improved insulation, and optimized airflow systems. By minimizing energy consumption and reducing environmental impact, these machines will align with sustainability goals while maintaining high processing efficiency.

4. Enhanced Food Safety Measures: With growing concerns about food safety and hygiene, future microwave seafood processing equipment will incorporate enhanced sanitation features, such as self-cleaning mechanisms and antimicrobial coatings. These measures help prevent cross-contamination and ensure the safety and integrity of processed seafood products.

As technology continues to advance, the future of microwave seafood processing holds exciting possibilities for increased efficiency, sustainability, and food safety, driving innovation in the food processing industry.

References

The following are five authoritative foreign literature websites in the field of industrial microwaves:

1. IEEE Xplore Digital Library

Website: [https://ieeexplore.ieee.org/]

2.ScienceDirect

Website: [https://www.sciencedirect.com/]

3. SpringerLink

Website: [https://link.springer.com/]

4. Wiley Online Library

Website: [https://onlinelibrary.wiley.com/]

5. PubMed

Website: [https://pubmed.ncbi.nlm.nih.gov/]

Telephone :+86-531-55583139

Telephone :+86-531-55583139 WhatsApp :+86 13256674591

WhatsApp :+86 13256674591 Email :

Email :