Everything You Need to Know About Microwave Meal Replacement Powder Sterilizing Machine in 2024

Introduction

In 2024, the demand for convenient and nutritious meal replacement options continues to rise, leading to advancements in food processing technology. One such innovation is the Microwave Meal Replacement Powder Sterilizing Machine, revolutionizing the way meal replacement powders are treated for safety and longevity.

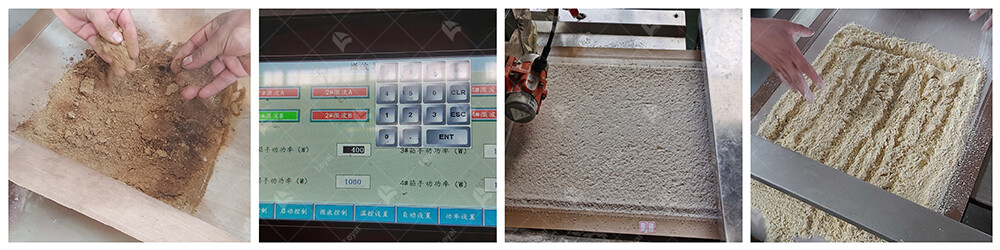

Microwave meal replacement powder Sterilizing Machine Operation Guide

1. Microwave Sterilizing Machine: Start by familiarizing yourself with the controls and settings of the Microwave Sterilizing Machine. Ensure it's clean and free of any residue from previous operations.

2. Preparation of Products: Before placing the products in the machine, make sure they are evenly spread out on the trays or conveyor belt. This ensures uniform sterilization.

3. Setting Parameters: Adjust the time and power settings on the machine according to the product requirements. Consult the manual for recommended settings based on the type and quantity of the product.

4. Monitoring: During the sterilization process, monitor the machine regularly to ensure everything is proceeding smoothly. Make any necessary adjustments to the settings if required.

5. Post-Sterilization: Once the sterilization cycle is complete, allow the products to cool before handling or packaging them. Inspect the products for any signs of contamination or irregularities.

Application of Microwave meal replacement powder Sterilizing Machine

In the food and beverage industry, the Application of Microwave meal replacement powder Sterilizing Machine is widespread, with manufacturers across the globe incorporating this technology into their production processes. From large-scale facilities to small-scale operations, this innovative equipment offers a cost-effective solution for ensuring product safety and quality.

Beyond conventional meal replacement powders, the Application of Microwave meal replacement powder Sterilizing Machine extends to a variety of other food products, including infant formula, powdered supplements, and sports nutrition products. With its ability to efficiently sterilize a wide range of formulations, this technology addresses the diverse needs of consumers seeking convenient and nutritious meal options.

Moreover, the Application of Microwave meal replacement powder Sterilizing Machine is not limited to food production alone. Industries such as pharmaceuticals, cosmetics, and animal feed also benefit from the sterilization capabilities of this advanced equipment. By maintaining stringent quality control standards and meeting regulatory requirements, manufacturers can ensure the safety and efficacy of their products across various sectors.

In the era of e-commerce and global supply chains, the Application of Microwave meal replacement powder Sterilizing Machine plays a crucial role in ensuring product integrity during transportation and storage. With its rapid sterilization capabilities, this technology helps mitigate the risk of contamination and spoilage, safeguarding the quality of meal replacement powders from production to consumption.

The Application of Microwave meal replacement powder Sterilizing Machine aligns with the growing consumer demand for clean-label products and sustainable manufacturing practices. By reducing the need for chemical preservatives and minimizing energy consumption, this technology supports environmentally friendly production methods while delivering safe and nutritious meal replacement options to consumers worldwide.

Choosing the Right Machinery of Microwave Meal Replacement Powder Sterilizing Machine

Selecting the right machinery for microwave meal replacement powder sterilization is essential for maximizing production efficiency, maintaining product quality, and ensuring regulatory compliance. Among the leading companies in this field, Loyal Stands out for its commitment to innovation and quality in herbal drying technology.By considering key factors such as technology integration, customization options, quality assurance, scalability, and after-sales support, food manufacturers can make informed decisions to meet their sterilization needs effectively.

Technical Parameters Of Continuous Microwave Dryer Industrial Microwave Drying Machine | |||||

| Model | Size L*W*H(Can be customized according to the customer's requirements) | Output power | Dewaterability | Sterilization capacity | Baking and Roasting capacity (Depends on different raw material) |

| LY-10KW | 5000mm*825mm*1750mm | ≥10KW | 10KG/Hour | 100KG/Hour | 30-50KG/Hour |

| LY-20KW | 8000mm*825mm*1750mm | ≥20KW | 20KG/Hour | 200KG/Hour | 60-100KG/Hour |

| LY-30KW | 8500mm*1160mm*1750mm | ≥30KW | 30KG/Hour | 300KG/Hour | 90-150 KG/Hour |

| LY-40KW | 10000mm*1160mm*1750mm | ≥40KW | 40KG/Hour | 40KG/Hour | 120-200KG/Hour |

| LY-50KW | 12500mm*1160mm*1750mm | ≥50KW | 50KG/Hour | 500KG/Hour | 150-250KG/Hour |

| LY-60KW | 13500mm*1450mm*1750mm | ≥60KW | 60KG/Hour | 600KG/Hour | 180-300KG/Hour |

| LY-70KW | 13500mm*1500mm*1750mm | ≥70KW | 70KG/Hour | 700KG/Hour | 210-350KG/Hour |

| LY-80KW | 13500mm*1650mm*1750mm | ≥80KW | 80KG/Hour | 800KG/Hour | 240-400KG/Hour |

| LY-100KW | 16800mm*1650mm*1750mm | ≥100KW | 100KG/Hour | 1000KG/Hour | 300-500KG/Hour |

| LY-150KW | 22400mm*1850mm*1750mm | ≥150KW | 150KG/Hour | 1500KG/Hour | 450-750KG/Hour |

| LY-200KW | 27000mm*1850mm*1750mm | ≥250KW | 250KG/Hour | 2500KG/Hour | 750-1250/Hour |

| LY-300KW | 32000mm*1850mm*1750mm | ≥300KW | 300KG/Hour | 3000KG/Hour | 900-1500KG/Hour |

Machine Types Suitable for Meal Replacement Sterilization:

Microwave technology has emerged as a game-changer in sterilization processes. This machine utilizes microwave radiation to heat the meal replacement powder, effectively killing harmful microorganisms. With precise temperature control and uniform heating, it ensures thorough sterilization while preserving the nutritional quality of the product.

Protein powders are essential components of meal replacement products. This specialized machine employs methods tailored to the unique characteristics of protein powders, such as gentle heating to avoid denaturation. It eliminates bacteria, molds, and other pathogens, meeting stringent quality standards for protein-based supplements.

Bean powders are popular ingredients in meal replacement formulations due to their rich nutritional profile. The Bean Powder Sterilization Machine employs a combination of heat and airflow to eradicate contaminants while maintaining the natural flavor and color of the beans. Its versatility makes it suitable for various types of bean powders, including soy, chickpea, and lentil.

Main Functions of Microwave Meal Replacement Powder Sterilizing Machine Equipment

The primary function of Microwave Meal Replacement Powder Sterilizing Machine equipment is to eliminate harmful bacteria, viruses, and fungi present in the powdered products. Through controlled exposure to microwave radiation, it achieves a high level of microbial reduction, ensuring product safety and shelf stability.

Unlike conventional sterilization methods that may compromise the nutritional integrity of food products, Microwave Meal Replacement Powder Sterilizing Machines preserve the nutritional quality of meal replacement powders. The rapid heating process minimizes nutrient loss, allowing consumers to enjoy products with optimal health benefits.

Another key function of these machines is to ensure uniform heating throughout the product, preventing hot spots and cold spots. By evenly distributing microwave energy, they guarantee thorough sterilization without overheating or undercooking, thereby enhancing product quality and consistency.

Microwave technology offers energy-efficient sterilization solutions compared to traditional methods such as steam or heat treatment. These machines consume less energy and require shorter processing times, contributing to cost savings and environmental sustainability.

Modern Microwave Meal Replacement Powder Sterilizing Machines are equipped with advanced automation features and precise temperature control systems. Operators can monitor and adjust the sterilization process in real-time, ensuring optimal results and compliance with regulatory requirements.

Understanding the Role of Industrial Microwave Dryers in Meal Replacement Powders

Microwave technology revolutionizes the sterilization process for meal replacement powders. By utilizing electromagnetic waves, these machines effectively eradicate harmful microorganisms while preserving the nutritional integrity of the product. In 2024, the demand for such advanced sterilization methods is at an all-time high, driving the adoption of Microwave Meal Replacement Powder Sterilizing Machines across the industry.

Within the realm of meal replacement powders, protein content is paramount. Protein Powder Sterilization Machines equipped with microwave technology ensure the efficient sterilization of protein powders without compromising their quality. This technological marvel has become indispensable for manufacturers striving to meet the rigorous standards of both safety and nutritional value.

Nutrition powder encompasses a diverse range of essential nutrients vital for overall health. Microwave-based sterilization offered by Nutrition Powder Sterilization Machines guarantees the preservation of these nutrients, safeguarding the nutritional profile of meal replacement powders. The emphasis on delivering wholesome nutrition to consumers drives the widespread adoption of such advanced sterilization techniques.

Importance of Quality Control in Microwave Meal Replacement Powder Sterilizing Machine

Beans are a common ingredient in meal replacement powders, providing a rich source of protein and fiber. Quality control measures implemented in Bean Powder Sterilization Machines ensure the elimination of contaminants while preserving the natural goodness of beans.Stringent quality control is imperative to uphold the reputation of manufacturers amidst growing consumer awareness regarding food safety.

The cornerstone of quality control lies within the Microwave Meal Replacement Powder Sterilizing Machine itself. Precise calibration and monitoring of microwave parameters guarantee effective sterilization while mitigating the risk of nutrient degradation. Manufacturers prioritize investing in state-of-the-art sterilization equipment to uphold product quality and consumer trust in 2024.

Protein powder is a key component of many meal replacement powders, providing essential nutrients for muscle growth and repair. Quality control measures integrated into Protein Powder Sterilization Machines are crucial for ensuring the purity and safety of the final product. Through rigorous testing and monitoring, manufacturers can detect and eliminate any potential contaminants, maintaining the integrity of the protein powder. As consumer demand for high-quality, safe nutrition continues to rise , the role of stringent quality control in Protein Powder Sterilization Machines cannot be overstated.

Nutrition powder encompasses a wide range of vitamins, minerals, and other essential nutrients vital for overall health. In the context of meal replacement powders, maintaining the nutritional value of these powders during the sterilization process is paramount. Nutrition Powder Sterilization Machines equipped with advanced quality control features ensure that the delicate balance of nutrients is preserved, delivering a product that meets the highest standards of quality and safety. As consumers become increasingly discerning about the products they consume, manufacturers rely on these machines to uphold their reputation and meet regulatory requirements .

Latest Innovations And Trends in Industrial Microwave Meal Replacement Powder Drying

Microwave technology has revolutionized the drying process for meal replacement powders. These machines utilize microwave radiation to rapidly and efficiently remove moisture from the powder, preserving its nutritional integrity and extending its shelf life. In 2024, manufacturers are increasingly adopting microwave sterilizing machines due to their speed and effectiveness.

Protein powders are a staple in meal replacement products, and the demand for sterile powders is ever-growing. With the advancements in technology, protein powder sterilization machines have become more sophisticated, incorporating features such as precise temperature control and automated processes. These machines ensure that protein powders are free from contaminants while retaining their nutritional value.

Bean powders, rich in protein and essential nutrients, are gaining popularity in meal replacement formulations. To meet the stringent safety standards, bean powder sterilization machines have evolved to utilize microwave technology. This allows for thorough sterilization of the powder, eliminating harmful bacteria and pathogens without compromising its nutritional content.

The demand for nutritionally balanced meal replacement powders has surged in recent years. As a result, manufacturers are investing in advanced sterilization machines to maintain the quality and safety of their products. Microwave sterilization machines offer a rapid and efficient solution, ensuring that nutrition powders are free from contaminants and safe for consumption.

The cornerstone of modern meal replacement powder production, microwave sterilizing machines, continues to undergo innovations. These machines feature enhanced sterilization capabilities, energy efficiency, and automation. With the ability to sterilize large quantities of powder in a short time, microwave sterilizing machines are indispensable in the food processing industry.

Construction of Microwave Meal Replacement Powder Sterilizing Machine

1. Microwave Chamber: This is the primary space where the sterilization process occurs. It is equipped with microwave-emitting devices that generate electromagnetic waves to kill bacteria and pathogens.

2. Conveyor System: Many Microwave Sterilizing Machines feature a conveyor belt system that moves the products through the sterilization chamber. This ensures uniform exposure to the microwave energy.

3. Control Panel: The control panel allows operators to set parameters such as time, temperature, and power level. It also displays important information about the sterilization process, such as cycle status and any error messages.

4. Safety Features: Modern Microwave Sterilizing Machines are equipped with various safety features to prevent accidents and ensure operator protection. These may include emergency stop buttons, interlocks, and sensors to detect overheating.

5. Cooling System: After sterilization, a cooling system helps lower the temperature inside the chamber, allowing the products to reach a safe handling temperature more quickly.

Advances in Microwave Meal Replacement Powder Sterilizing Machine

In 2024, microwave sterilizing machines have achieved unprecedented levels of sterilization efficiency. Through precise control of microwave radiation and airflow, these machines can eliminate a wide range of contaminants, including bacteria, molds, and viruses, without compromising the nutritional quality of the powder.

With sustainability becoming a key focus in industrial operations, microwave sterilizing machines have been redesigned for improved energy efficiency. Advanced insulation materials and optimized heating mechanisms minimize energy wastage, reducing both operational costs and environmental impact.

Automation has revolutionized the operation of microwave sterilizing machines, streamlining processes and ensuring consistency in sterilization outcomes. These machines are equipped with advanced control systems that monitor and adjust parameters in real-time, optimizing sterilization efficiency and product quality.

The integration of Internet of Things (IoT) technology has enabled remote monitoring and management of microwave sterilizing machines. Manufacturers can now monitor sterilization processes, receive real-time alerts, and access performance data from anywhere, enhancing operational efficiency and quality control.

Modern microwave sterilizing machines offer greater customization options to meet the diverse needs of manufacturers. With adjustable parameters such as temperature, humidity, and exposure time, these machines can accommodate a wide range of powder formulations, ensuring thorough sterilization while preserving the nutritional integrity of the product.

Advantages Of Using A Microwave meal replacement powder Sterilizing Machine

Microwave meal replacement powder Sterilizing Machine: One of the primary advantages of using a Microwave meal replacement powder Sterilizing Machine is its unparalleled speed and efficiency. Unlike conventional sterilization processes that can take hours, this machine utilizes microwave technology to rapidly and effectively eliminate harmful bacteria, pathogens, and contaminants from meal replacement powders.

Protein Powder Sterilization Machine: Another key advantage is the preservation of nutritional quality. Protein powders are a staple in meal replacement products, providing essential nutrients for consumers. With the Protein Powder Sterilization Machine, the delicate balance of amino acids and protein structures remains intact, ensuring that consumers receive the full nutritional benefits without compromise.

Bean Powder Sterilization Machine: Additionally, the versatility of the Bean Powder Sterilization Machine allows for the sterilization of various types of meal replacement powders, including bean-based formulations. This flexibility enables manufacturers to cater to a diverse range of dietary preferences and restrictions, expanding their market reach and appeal.

Nutrition Powder Sterilization Machine: Moreover, the Nutrition Powder Sterilization Machine offers precise control over the sterilization process, minimizing the risk of over-processing and preserving the sensory attributes of the product. Unlike traditional methods that can result in flavor loss and texture degradation, this advanced technology ensures that meal replacement powders retain their taste, aroma, and mouthfeel.

Microwave meal replacement powder Sterilizing Machine: Finally, the Microwave meal replacement powder Sterilizing Machine enhances product shelf-life and safety. By effectively eliminating microbial contamination, manufacturers can extend the storage stability of their products without the need for added preservatives or artificial additives. This not only improves the overall quality of the meal replacement powders but also enhances consumer confidence in their safety and efficacy.

Utilizing YouTube for Knowledge on Industrial Microwave Drying

With the advent of the digital age, accessing information has never been easier. YouTube, in particular, has emerged as a valuable resource for learning about industrial microwave drying and related technologies. Whether you're a manufacturer looking to invest in new equipment or an enthusiast curious about the latest innovations, YouTube offers a wealth of educational content.

One of the primary advantages of using YouTube for learning about industrial microwave drying is the accessibility of information. With just a few clicks, users can access a wide range of videos covering various aspects of microwave drying technology. Whether it's instructional videos from equipment manufacturers or educational content from industry experts, YouTube provides a platform for sharing knowledge in a user-friendly format.

Another benefit of utilizing YouTube for industrial microwave drying knowledge is the visual learning experience it offers. Many complex concepts and processes can be better understood through visual demonstrations. YouTube videos often include animations, demonstrations, and real-life examples that help viewers grasp the principles of microwave drying more effectively than text-based resources alone.

YouTube also facilitates community engagement and interaction, allowing viewers to connect with content creators and fellow enthusiasts. Through comments, forums, and live streams, users can ask questions, share insights, and engage in discussions about industrial microwave drying and related topics. This sense of community fosters learning and collaboration, enabling individuals to gain deeper insights and perspectives.

Additionally, YouTube serves as a platform for staying updated on the latest industry trends and innovations in industrial microwave drying. Content creators often share news, updates, and case studies highlighting the applications and advancements of microwave drying technology. By subscribing to relevant channels and following industry influencers, users can stay informed about emerging technologies, best practices, and opportunities for optimization in their operations.

Using Microwave Technology to Improve Meal Replacement Powder Drying Production Efficiency

Microwave technology revolutionizes the drying process of meal replacement powder by offering rapid and uniform heating. Microwave meal replacement powder sterilizing machine utilizes electromagnetic waves to penetrate the powder, effectively eliminating moisture content and microbial contaminants. This technology ensures consistent product quality and extends shelf life.

The utilization of microwave meal replacement powder sterilizing machines significantly reduces processing time, leading to enhanced production efficiency. Traditional drying methods often entail prolonged processing durations, whereas microwave technology accelerates the drying process, thereby optimizing productivity.

Microwave technology preserves the nutritional integrity of meal replacement powder by minimizing heat exposure. Unlike conventional drying methods, which may degrade sensitive nutrients, microwave meal replacement powder sterilizing machines maintain the product's nutritional value, meeting consumer demands for healthier food options.

The integration of microwave technology in meal replacement powder drying processes offers unparalleled efficiency, quality, and nutritional preservation, making it a preferred choice for food manufacturers.

Expertise of Microwave Meal Replacement Powder Drying Engineers

Microwave meal replacement powder drying engineers play a crucial role in the development and optimization of sterilization processes. These professionals possess specialized knowledge and skills in the field of microwave technology and food processing. Their expertise enables them to design and implement efficient drying and sterilization protocols tailored to the specific requirements of powdered food products.

One area of expertise for microwave meal replacement powder drying engineers is understanding the complex interactions between microwave energy and food particles. They must optimize factors such as frequency, power level, and exposure time to achieve thorough sterilization without compromising product quality.

Microwave meal replacement powder drying engineers are well-versed in the principles of heat and mass transfer, which are essential for designing effective sterilization systems. They utilize advanced modeling and simulation techniques to predict the behavior of powdered food products during the sterilization process, allowing for precise control and optimization of key parameters.

Microwave meal replacement powder drying engineers are knowledgeable about regulatory requirements and industry standards governing food safety and quality. They work closely with regulatory agencies to ensure that sterilization processes comply with applicable guidelines and regulations.

Literature Reference

1. IEEE Xplore Digital Library (https://ieeexplore.ieee.org/)

2. ScienceDirect (https://www.sciencedirect.com/)

3. Wiley Online Library (https://onlinelibrary.wiley.com/)

4. SpringerLink (https://link.springer.com/)

5.Taylor & Francis Online (https://www.tandfonline.com/)

Microwave Meal Replacement Powder Sterilizing Machine Frequently Asked Questions (FAQs)

1. What is a Microwave Meal Replacement Powder Sterilizing Machine?

A Microwave Meal Replacement Powder Sterilizing Machine is an advanced piece of equipment used in the food processing industry to sterilize meal replacement powders using microwave technology. It offers a fast, efficient, and environmentally friendly solution for eliminating harmful bacteria and pathogens while preserving the nutritional integrity of the powder.

2. How does a Microwave Meal Replacement Powder Sterilizing Machine work?

The machine works by exposing the meal replacement powder to microwave radiation, which effectively kills bacteria and other microorganisms present in the powder. Unlike traditional sterilization methods that rely on heat or chemicals, microwave sterilization is quick and does not compromise the quality or nutritional value of the product.

3. Is microwave sterilization safe for meal replacement powders?

Yes, microwave sterilization is considered safe for meal replacement powders. The process effectively eliminates harmful bacteria and pathogens while meeting stringent safety standards set by regulatory authorities. Additionally, microwave sterilization does not introduce any harmful chemicals or residues into the product, ensuring its safety for consumption.

3. Can different types of meal replacement powders be sterilized using the same machine?

Yes, Microwave Meal Replacement Powder Sterilizing Machines are designed to accommodate various types of meal replacement powders, including protein powders, bean powders, nutrition powders, and more. The versatility of these machines allows manufacturers to sterilize a wide range of products without the need for separate equipment.

5. What are the maintenance requirements for a Microwave Meal Replacement Powder Sterilizing Machine?

Maintenance requirements may vary depending on the specific machine model and manufacturer. However, regular cleaning and inspection of components, such as the microwave emitter, conveyor belts, and control systems, are essential to ensure optimal performance and longevity of the equipment. Manufacturers typically provide maintenance guidelines and schedules to help operators keep the machine in good working condition.

6. Are there any regulatory standards or certifications for Microwave Meal Replacement Powder Sterilizing Machines?

Yes, manufacturers of these machines must adhere to regulatory standards and obtain certifications to ensure compliance with food safety regulations. Common certifications include ISO (International Organization for Standardization) standards and certifications from regulatory bodies such as the FDA (Food and Drug Administration) or equivalent organizations in other countries. Additionally, manufacturers may conduct internal quality control and testing to ensure their machines meet industry standards.

Telephone :+86-531-55583139

Telephone :+86-531-55583139 WhatsApp :+86 13256674591

WhatsApp :+86 13256674591 Email :

Email :