Everything you Need to Know About Microwave Lily Flower Drying and Sterilizer Machine

Introduction to Microwave Lily Flower Drying and Sterilizer Machine

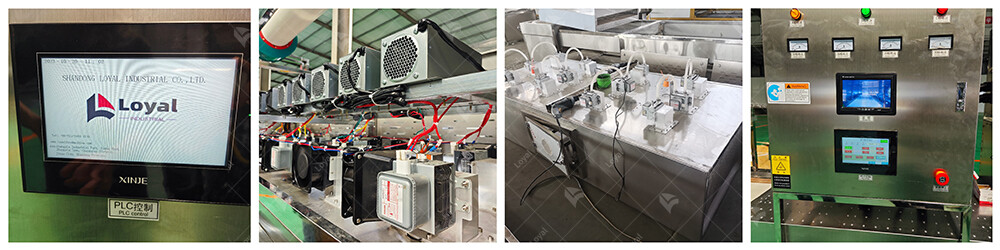

Microwave Lily Flower Drying and Sterilizer Machine revolutionizes the process of drying and sterilizing lily flowers, ensuring efficiency and quality. This industrial equipment combines the power of microwaves with precision control mechanisms to expedite the drying and sterilization process.

Utilizing advanced microwave technology, this machine offers a swift and effective solution for preserving the freshness and quality of lily flowers. By harnessing electromagnetic waves, it rapidly removes moisture while simultaneously eliminating harmful pathogens, ensuring extended shelf life and safety.

With its user-friendly interface and customizable settings, operators can easily adjust parameters to meet specific drying and sterilization requirements, making it an indispensable tool in the food processing industry.

History of Microwave Technology in Food Processing

Microwave technology has a rich history in food processing, dating back to its discovery in the early 20th century. Initially developed for telecommunications, it wasn't until the mid-20th century that its potential for heating food was realized.

The application of microwaves in food processing gained traction during World War II, with the invention of the Radarange microwave oven by Percy Spencer in 1946. This marked the beginning of microwave technology's integration into the food industry, offering a faster and more efficient alternative to conventional cooking methods.

Throughout the decades, advancements in microwave technology have led to the development of sophisticated equipment tailored for specific food processing tasks. From thawing and heating to drying and sterilizing, microwaves have become integral to various stages of food production.

In recent years, the focus has shifted towards enhancing the efficiency and precision of microwave systems, leading to the introduction of specialized equipment such as the Microwave Lily Flower Drying and Sterilizer Machine. This represents a significant milestone in the evolution of microwave technology, catering to the unique needs of the food processing industry.

Benefits of Microwave Drying and Sterilization for Lily Flowers

Benefits | Description |

| Faster Processing | Microwave drying and sterilization machines offer rapid processing times, reducing overall production duration. |

| Improved Product Quality | Maintains the color, flavor, and nutritional content of lily flowers compared to traditional drying methods. |

| Energy Efficiency | Utilizes energy more efficiently compared to conventional drying methods, resulting in lower operating costs. |

| Enhanced Sterilization | Provides thorough sterilization, eliminating harmful bacteria and pathogens effectively. |

| Preserves Aesthetic Appeal | Retains the natural appearance and shape of lily flowers during the drying and sterilization process. |

| Environmentally Friendly | Reduces carbon footprint due to reduced energy consumption and shorter processing times. |

| Extended Shelf Life | Increases the shelf life of lily flowers by preventing microbial growth and preserving freshness. |

| Uniform Drying | Ensures uniform drying and sterilization throughout the batch, minimizing product inconsistencies. |

| Reduced Labor Costs | Requires minimal manual intervention, reducing labor costs associated with production. |

| Versatility | Can be adapted for various types of lily flowers and other similar botanicals, enhancing versatility in production. |

Understanding the Science Behind Microwave Drying

Microwave drying operates on the principle of dielectric heating, where microwave energy penetrates the material and causes water molecules within the lily flowers to oscillate rapidly. This agitation generates heat, effectively evaporating moisture from the flowers. Unlike conventional drying methods that rely on conduction or convection, microwave drying heats the material internally, leading to faster and more uniform drying.

The frequency of the microwave radiation is carefully controlled to match the resonant frequency of water molecules, maximizing energy absorption and minimizing energy loss. This targeted heating process ensures efficient drying while preserving the quality attributes of the lily flowers.

Additionally, microwave sterilization utilizes the thermal effect of microwave energy to rapidly raise the temperature of the flowers, effectively killing microorganisms and pathogens present on the surface and within the plant material. The combination of drying and sterilization in a single process streamlines production and enhances product safety.

Moreover, the precise control and modulation of microwave power allow for customizable drying profiles, accommodating different types of lily flowers and optimizing the process for specific quality parameters. Overall, understanding the science behind microwave drying and sterilization is crucial for maximizing efficiency and quality in industrial food processing applications.

Components and Functionality of a Microwave Lily Flower Drying and Sterilizer Machine

Component | Functionality |

| Magnetron | Generates microwave energy for heating the lily flowers |

| Waveguide | Transfers microwave energy from the magnetron to the drying chamber |

| Drying Chamber | Enclosed space where lily flowers are placed for drying and sterilization |

| Turntable | Rotates the lily flowers inside the drying chamber for even exposure to microwave energy |

| Temperature Sensor | Monitors the temperature inside the drying chamber to ensure optimal drying conditions |

| Control Panel | Interface for operators to set parameters such as temperature, time, and power level for the drying process |

| Exhaust System | Removes excess moisture and gases released during the drying and sterilization process, maintaining chamber conditions |

| Safety Interlocks | Prevents the machine from operating if the chamber door is open or if there are other safety hazards present |

Comparison with Traditional Drying Methods

Aspect | Microwave Lily Flower Drying and Sterilizer Machine | Traditional Drying Methods |

| Speed | Rapid drying process, reducing processing time and increasing throughput | Slower drying process, requiring more time and labor |

| Energy Efficiency | More energy-efficient due to targeted heating of lily flowers | Less energy-efficient, as heat is dispersed over a surface |

| Quality Preservation | Preserves the color, flavor, and nutritional value of lily flowers | May result in color and flavor loss due to prolonged heat exposure |

| Sterilization Capability | Provides sterilization alongside drying, eliminating harmful bacteria and pathogens | Limited sterilization capability, may require additional steps for safety |

| Space Requirement | Compact design, suitable for small-scale and industrial settings | Requires larger drying space, may be impractical for some settings |

| Environmental Impact | Reduced greenhouse gas emissions and carbon footprint due to shorter processing time | May contribute to higher greenhouse gas emissions and energy consumption |

| Cost-effectiveness | Initial investment may be higher, but lower operating costs over time | Lower initial investment, but higher operating costs due to longer processing times |

Best Practices for Operating Microwave Drying and Sterilization Equipment

1. Calibration and Maintenance: Regular calibration of the Microwave Lily Flower Drying and Sterilizer Machine is essential to ensure optimal performance. Follow manufacturer guidelines for maintenance schedules, including cleaning the interior and exterior surfaces to prevent buildup that can affect functionality.

2. Loading and Unloading Procedures: Proper loading of lily flowers into the machine ensures uniform drying and sterilization. Arrange flowers in a single layer on trays, avoiding overcrowding to allow for even exposure to microwave energy. Similarly, follow specific guidelines for unloading to prevent damage to dried flowers and ensure efficiency.

3. Monitoring and Control: Utilize the equipment's monitoring systems to maintain precise control over drying and sterilization parameters. Regularly check temperature and humidity levels within the machine, adjusting settings as needed to achieve desired results while avoiding over-processing or under-processing.

4. Training and Supervision: Ensure operators receive comprehensive training on the operation of the Microwave Lily Flower Drying and Sterilizer Machine. Emphasize safety protocols, proper handling of equipment, and adherence to operating procedures to minimize the risk of accidents and optimize performance.

Safety Precautions and Regulatory Compliance

1. Electrical Safety: Prioritize electrical safety by ensuring the Microwave Lily Flower Drying and Sterilizer Machine is properly grounded and installed according to manufacturer specifications. Regularly inspect power cords and connections for signs of wear or damage, and promptly address any issues to prevent electrical hazards.

2. Personal Protective Equipment (PPE): Provide operators with appropriate PPE, including gloves and eye protection, when handling lily flowers or operating the sterilization equipment. Emphasize the importance of wearing PPE to prevent injury and minimize exposure to potentially harmful substances.

3. Ventilation and Exhaust Systems: Maintain adequate ventilation and exhaust systems to remove steam and fumes generated during the drying and sterilization process. Ensure these systems are in good working condition to promote a safe working environment and prevent the accumulation of hazardous gases.

- Regulatory Compliance: Familiarize yourself with relevant regulations and standards governing the operation of food processing equipment, including microwave drying and sterilization machinery. Ensure compliance with requirements related to food safety, sanitation, and environmental protection to mitigate risks and maintain regulatory compliance.

Maintenance and Cleaning Guidelines for Microwave Sterilizer Machine

To ensure optimal performance and longevity of your Microwave Sterilizer Machine, regular maintenance and cleaning are essential. Neglecting these tasks can lead to decreased efficiency and potential breakdowns, impacting production schedules and product quality.

Start by disconnecting the machine from its power source before beginning any maintenance or cleaning procedures. This ensures safety for the operator and prevents any accidental damage to the equipment.

For routine maintenance, inspect the internal components of the Microwave Sterilizer Machine for any signs of wear or damage. Replace any worn-out parts promptly to prevent further issues. Additionally, lubricate moving parts as recommended by the manufacturer to keep them functioning smoothly.

Cleaning the Microwave Sterilizer Machine should be done regularly to remove any buildup of residue or contaminants. Use a mild detergent solution and a soft cloth to wipe down the interior surfaces. Pay particular attention to areas prone to buildup, such as the chamber walls and conveyor belts.

After cleaning, thoroughly rinse all surfaces with clean water to remove any remaining detergent residue. Allow the machine to dry completely before reconnecting it to the power source and resuming operations. Following these maintenance and cleaning guidelines will help ensure the continued efficiency and reliability of your Microwave Sterilizer Machine.

Future Trends in Microwave Technology for Food Processing

As technology continues to advance, the future of microwave technology in food processing looks promising. Researchers and manufacturers are constantly innovating to improve efficiency, reduce energy consumption, and enhance product quality.

One emerging trend is the integration of artificial intelligence (AI) and machine learning algorithms into Microwave Sterilizer Machines. These technologies can optimize processing parameters in real-time, leading to more precise control and consistent results.

Another area of development is the use of advanced materials in microwave components, such as ceramics and composites. These materials offer improved durability and heat resistance, allowing for higher temperatures and faster processing times.

Wireless connectivity is also becoming more prevalent in Microwave Sterilizer Machines, enabling remote monitoring and control. This enhances convenience for operators and allows for more efficient management of multiple machines in large-scale food processing facilities.

Overall, the future of microwave technology in food processing holds great potential for enhancing productivity, quality, and sustainability. By staying abreast of these trends and incorporating the latest innovations into their operations, food manufacturers can remain competitive in an ever-evolving industry landscape.

Conclusion

The Microwave Lily Flower Drying and Sterilizer Machine represents a significant advancement in food processing technology, combining efficiency, precision, and innovation. From understanding its historical context to grasping the intricate science behind microwave drying, this machine has revolutionized the way lily flowers and other food products are processed. The benefits of using microwave technology for drying and sterilization are manifold, including enhanced product quality, reduced processing times, and improved safety.

A detailed examination of the components and functionality of the Microwave Lily Flower Drying and Sterilizer Machine reveals a complex yet user-friendly design that stands out compared to traditional drying methods. Emphasizing best practices for operation ensures optimal performance and product consistency, while strict adherence to safety precautions and regulatory compliance safeguards both operators and consumers.

Regular maintenance and cleaning are crucial for the longevity and reliability of the Microwave Sterilizer Machine, and understanding these procedures can prevent costly downtimes. Looking forward, future trends in microwave technology, such as AI integration and advanced materials, promise even greater efficiency and sustainability in food processing.

Overall, the Microwave Lily Flower Drying and Sterilizer Machine is poised to play a pivotal role in the future of food processing, offering unparalleled advantages that meet the growing demands of the industry.

FAQs: Frequently Asked Questions about Microwave Lily Flower Drying and Sterilizer Machine

1. What is a Microwave Lily Flower Drying and Sterilizer Machine?

The Microwave Lily Flower Drying and Sterilizer Machine is an advanced piece of equipment designed to efficiently dry and sterilize lily flowers using microwave technology. This machine combines the processes of drying and sterilization in one unit, making it ideal for preserving the quality and extending the shelf life of lily flowers.

2. How does the microwave technology work in this machine?

Microwave technology works by emitting electromagnetic waves that penetrate the lily flowers, causing water molecules within the flowers to vibrate and generate heat. This heat effectively dries the flowers while the microwave energy also acts to sterilize by destroying bacteria, fungi, and other microorganisms.

3. What are the benefits of using a Microwave Lily Flower Drying and Sterilizer Machine?

The benefits include faster drying times, more uniform drying, preservation of color and nutritional content, and the ability to sterilize simultaneously. This leads to higher quality products, increased efficiency, and reduced energy consumption compared to traditional drying methods.

4. How do I maintain and clean the Microwave Lily Flower Drying and Sterilizer Machine?

Regular maintenance involves inspecting components for wear and tear, replacing any damaged parts, and lubricating moving parts as needed. Cleaning should be done using a mild detergent and soft cloth to wipe down the interior, followed by a thorough rinse with clean water. Always ensure the machine is disconnected from the power source before performing maintenance or cleaning.

References

1. Website: Food Processing Technology

URL: https://www.foodprocessing-technology.com/

2. Website: Food Engineering Magazine

URL: https://www.foodengineeringmag.com/

3. Website: Food Manufacturing Magazine

URL: https://www.foodmanufacturing.com/

4. Website: Packaging Digest

URL: https://www.packagingdigest.com/

5. Website: Food Quality & Safety Magazine

Telephone :+86-531-55583139

Telephone :+86-531-55583139 WhatsApp :+86 13256674591

WhatsApp :+86 13256674591 Email :

Email :