Everything you Need to Know About Microwave Drying and Baking Saffron Machine

Introduction to Microwave Drying and Baking Saffron Machines

Microwave drying and baking saffron machines represent cutting-edge technology in the food processing industry, specifically designed for the efficient drying and baking of saffron using microwave energy. These machines utilize advanced microwave technology to achieve rapid and uniform heating, preserving the quality and flavor of saffron while enhancing production efficiency.

Microwave drying and baking saffron machines are equipped with specialized chambers where saffron is subjected to controlled microwave energy. Unlike conventional drying and baking methods that rely on convection or conduction heat transfer, microwave technology directly heats the moisture within the saffron, leading to faster drying and baking times.

Moreover, these machines offer precise temperature and moisture control, ensuring optimal drying and baking conditions for saffron while minimizing energy consumption. The ability to adjust parameters such as power level and processing time enables operators to customize the drying and baking process according to specific requirements, resulting in consistent product quality.

In addition to their efficiency and versatility, microwave drying and baking saffron machines are also known for their compact design and user-friendly interface. They are suitable for both small-scale and large-scale production facilities, offering flexibility and scalability to meet varying production demands.

Advantages of Using Microwave Technology for Drying and Baking

The utilization of microwave technology for drying and baking offers numerous advantages over traditional methods, making it a preferred choice in the food processing industry. These advantages stem from the unique heating mechanism and precise control capabilities inherent to microwave technology.

First and foremost, microwave technology enables rapid and uniform heating of the product, resulting in significantly reduced processing times compared to conventional methods. This accelerated heating not only improves production efficiency but also helps preserve the nutritional content and sensory attributes of the food product.

Furthermore, microwave drying and baking require minimal preheating time, allowing for instant and on-demand processing. This on-demand capability reduces energy consumption and operational costs associated with prolonged heating and idle times, making microwave technology a more sustainable option for food processing.

Another key advantage of microwave drying and baking is the ability to achieve precise temperature and moisture control. By adjusting microwave power levels and processing times, operators can tailor the drying and baking process to meet specific product requirements, ensuring consistent quality and texture.

Moreover, microwave technology offers versatility in processing a wide range of food products, including delicate herbs like saffron. Unlike traditional methods that may cause over-drying or uneven heating, microwave technology provides gentle and uniform heating, preserving the delicate flavors and aromas of the food product.

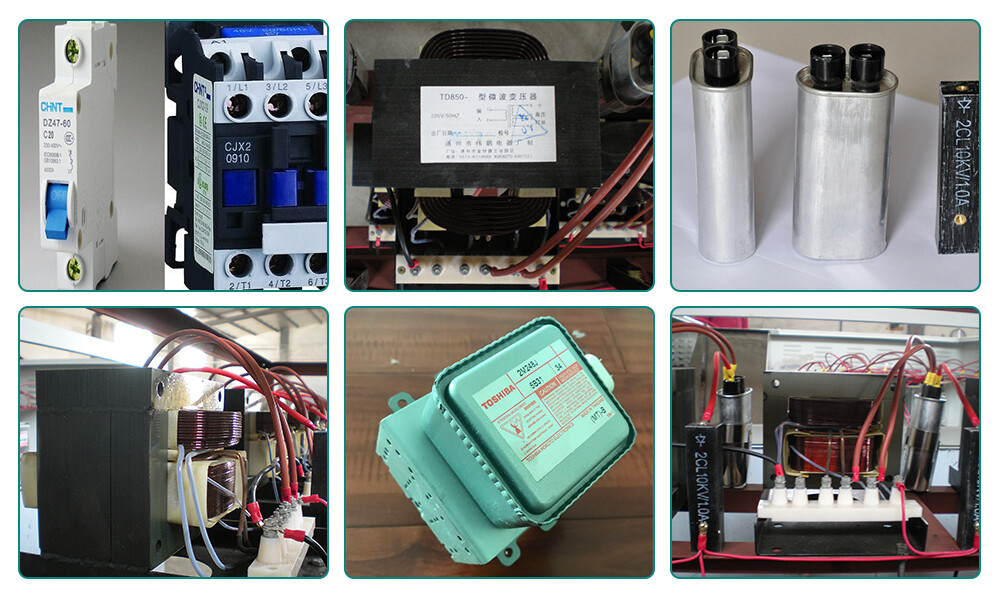

Key Components of Microwave Drying and Baking Saffron Machines

Microwave drying and baking saffron machines consist of several key components that work together to achieve efficient and precise processing of saffron using microwave energy. These components are designed to facilitate heating, moisture removal, and temperature control within the processing chamber.

The primary component of microwave drying and baking saffron machines is the microwave generator, which produces microwave energy at specific frequencies tailored to the moisture content and properties of saffron. This energy is then transmitted to the processing chamber via waveguides or antennae, where it interacts with the saffron to induce heating.

Within the processing chamber, saffron is placed on trays or conveyor belts, allowing for even exposure to microwave energy. The chamber is typically equipped with temperature and moisture sensors to monitor and regulate processing conditions in real-time, ensuring optimal drying and baking results.

Additionally, microwave drying and baking saffron machines may feature auxiliary components such as ventilation systems, which help remove moisture evaporated from the saffron during processing, preventing condensation and ensuring product quality.

Furthermore, modern machines may incorporate advanced control systems with intuitive interfaces, allowing operators to monitor and adjust processing parameters such as microwave power, temperature, and processing time. These control systems enable precise customization of the drying and baking process according to specific product requirements, ensuring consistent quality and efficiency.

Operating Principles of Microwave Drying and Baking Saffron Machines

Microwave drying and baking saffron machines utilize advanced technology to efficiently process saffron while preserving its quality and flavor. The operating principles of these machines involve several key steps to achieve optimal results.

Firstly, the saffron is loaded into the microwave drying and baking chamber, where it is evenly spread out to ensure uniform exposure to microwaves. These microwaves are generated by a magnetron and directed into the chamber, where they penetrate the saffron material.

Secondly, the microwaves interact with the water molecules present in the saffron, causing them to vibrate rapidly and generate heat through friction. This heat accelerates the drying process by removing moisture from the saffron efficiently and effectively.

Thirdly, the microwave drying and baking saffron machine incorporates precise temperature and humidity control mechanisms to regulate the drying process. By monitoring and adjusting these parameters in real-time, the machine ensures that the saffron is dried and baked to the desired moisture content and texture.

Lastly, the dried and baked saffron is carefully removed from the machine and undergoes quality control checks to verify its moisture content, color, aroma, and flavor. Once the saffron meets the specified quality standards, it is ready for packaging and distribution to pet food manufacturers or other end users.

Applications of Microwave Drying and Baking in the Pet Food Industry

Microwave drying and baking technology offers numerous applications in the pet food industry, providing pet food manufacturers with a versatile and efficient solution for processing various ingredients, including saffron.

One of the primary applications of microwave drying and baking in the pet food industry is the production of high-quality pet treats and snacks. Saffron, known for its aromatic and flavorful properties, can be incorporated into pet treats to enhance their palatability and appeal to pets. Microwave drying and baking saffron machines enable manufacturers to efficiently process saffron-infused treats while preserving its natural color, aroma, and flavor.

Additionally, microwave drying and baking technology can be used to produce specialized pet food formulations tailored to meet specific dietary requirements or preferences. For example, saffron may be included in premium pet food recipes targeting health-conscious pet owners seeking natural and wholesome ingredients for their pets. By using microwave drying and baking saffron machines, manufacturers can ensure consistent quality and nutritional integrity in their pet food products.

Moreover, microwave drying and baking technology enable pet food manufacturers to optimize production efficiency and reduce processing times. The rapid and uniform heating provided by microwave technology accelerates the drying and baking process, allowing for higher throughput and increased productivity. This is particularly advantageous in the pet food industry, where demand for innovative and high-quality products continues to grow.

In conclusion, the applications of microwave drying and baking in the pet food industry extend beyond traditional food processing methods, offering pet food manufacturers opportunities to enhance product quality, innovation, and efficiency. By leveraging microwave technology, manufacturers can create premium pet food products that meet the evolving needs and preferences of pet owners worldwide.

Maintenance and Cleaning Guidelines for Optimal Performance

Proper maintenance and regular cleaning are essential for ensuring the optimal performance and longevity of Microwave Drying and Baking Saffron Machines. Neglecting maintenance can lead to decreased efficiency, increased downtime, and potential safety hazards.

Firstly, it's crucial to follow the manufacturer's maintenance schedule and guidelines. This typically involves routine inspections, lubrication of moving parts, and replacement of worn components. Regular maintenance helps identify potential issues early on, preventing costly repairs and minimizing downtime.

Secondly, cleanliness is paramount in maintaining hygiene and preventing contamination in the food processing environment. After each use, the microwave drying and baking saffron machine should be thoroughly cleaned using approved sanitizers and detergents. Pay particular attention to areas prone to food buildup, such as the drying chamber and conveyor belts.

Additionally, inspect and clean the ventilation system regularly to ensure proper airflow and prevent overheating. Accumulated debris or blockages can hinder airflow, affecting the drying and baking process. Use compressed air or vacuum cleaners to remove any dirt or debris from vents and ducts.

Furthermore, conduct periodic calibration checks on temperature and humidity sensors to ensure accurate readings. Inaccurate sensor readings can lead to inconsistent drying or baking results. Calibration should be performed by qualified technicians using calibrated equipment.

Factors to Consider When Choosing a Microwave Drying and Baking Saffron Machine

When selecting a microwave drying and baking saffron machine, several factors should be considered to ensure that it meets your specific needs and requirements. A comparison between LOYAL company's machine and AXOR company's machine can help in making an informed decision.

Factors | LOYAL Company's Machine | AXOR Company's Machine |

Price | Affordable | Higher price point |

Capacity | Suitable for small to medium-scale production | Designed for larger-scale operations |

Technology | Utilizes advanced microwave drying and baking technology | Employs traditional drying and baking methods |

Energy Efficiency | Offers high energy efficiency | Energy-efficient, but may consume more power |

Customization Options | Limited customization options | Offers greater customization according to client needs |

Maintenance Requirements | Requires minimal maintenance | May require more frequent maintenance due to complexity |

In summary, when choosing between LOYAL and AXOR company's microwave drying and baking saffron machines, factors such as price, capacity, technology, energy efficiency, customization options, and maintenance requirements should be carefully evaluated to determine which machine best aligns with your production goals and budget.

Safety Precautions for Operating Microwave Drying and Baking Saffron Machines

Operating microwave drying and baking saffron machines requires strict adherence to safety precautions to minimize the risk of accidents and ensure the well-being of personnel.

Firstly, ensure that all operators receive proper training on the safe use and operation of the machine. Training should include instructions on handling saffron, operating controls, emergency procedures, and safety protocols.

Secondly, establish clear operating procedures and safety guidelines for all personnel working with the machine. Emphasize the importance of wearing appropriate personal protective equipment (PPE), such as gloves, goggles, and aprons, to prevent exposure to hot surfaces and steam.

Additionally, regularly inspect the machine for any signs of wear, damage, or malfunction that could pose a safety hazard. Promptly address any issues identified during inspections and perform necessary repairs or replacements as required.

Furthermore, implement proper ventilation systems to minimize exposure to fumes and vapors generated during the drying and baking process. Adequate ventilation helps maintain a safe working environment and prevents the accumulation of potentially harmful gases.

In conclusion, prioritizing safety precautions, training, and regular maintenance is essential for safe operation when using microwave drying and baking saffron machines. By following established safety protocols and guidelines, operators can minimize risks and ensure a safe working environment.

Innovations and Trends in Microwave Drying and Baking Technology

In the realm of microwave drying and baking technology, continual innovation and emerging trends shape the landscape of pet food production. These advancements drive efficiency, quality, and sustainability in the industry, ensuring the optimal utilization of resources while meeting the growing demand for nutritious pet food.

One notable innovation in microwave drying and baking technology is the integration of artificial intelligence (AI) and machine learning algorithms. By harnessing AI capabilities, manufacturers can optimize drying and baking processes in real-time, adjusting parameters such as temperature, humidity, and duration for maximum efficiency and product quality. This adaptive approach enhances consistency and reduces energy consumption, making it a promising trend for the future of pet food production.

Another trend is the development of multifunctional microwave drying and baking systems. These systems are designed to handle a variety of ingredients and formulations, offering versatility and flexibility to pet food manufacturers. By accommodating diverse product requirements, such as different moisture levels or baking profiles, these systems streamline production processes and enable customized pet food solutions.

In conclusion, ongoing innovations and trends in microwave drying and baking technology are driving significant improvements in pet food production. From AI-driven optimization and multifunctional systems to sustainability initiatives and technological advancements, these developments underscore the industry's commitment to delivering high-quality, nutritious pet food efficiently and responsibly.

Case Studies Highlighting Success Stories in Production

Several case studies illustrate the successful implementation of microwave drying and baking technology in production, highlighting its efficacy and benefits in various contexts.

One case study involves a manufacturer seeking to improve the shelf-life and nutritional quality of their products while reducing energy consumption. By adopting a microwave drying and baking saffron machine, they achieved significant improvements in drying efficiency and product consistency. The precise control offered by the technology resulted in uniform moisture content and enhanced flavor retention, leading to higher consumer satisfaction and brand loyalty.

In another case study, a startup aimed to differentiate their products in a competitive market by offering unique formulations and textures. With the flexibility provided by a multifunctional microwave drying and baking system, they were able to experiment with different ingredients and baking profiles, creating innovative varieties tailored to specific dietary preferences and requirements. This versatility allowed them to quickly adapt to changing consumer trends and preferences, driving sales growth and market expansion.

These case studies demonstrate the diverse applications and benefits of microwave drying and baking technology in production, from improving product quality and consistency to enhancing innovation and scalability. As more manufacturers recognize the value of this technology, its adoption is expected to continue growing, driving further advancements and success stories in the industry.

References

The following are five authoritative foreign literature websites in the field of industrial microwaves:

1. IEEE Xplore Digital Library

Website: [https://ieeexplore.ieee.org/]

2.ScienceDirect

Website: [https://www.sciencedirect.com/]

3. SpringerLink

Website: [https://link.springer.com/]

4. Wiley Online Library

Website: [https://onlinelibrary.wiley.com/]

5. PubMed

Website: [https://pubmed.ncbi.nlm.nih.gov/]

Telephone :+86-531-55583139

Telephone :+86-531-55583139 WhatsApp :+86 13256674591

WhatsApp :+86 13256674591 Email :

Email :