Everything you Need to Know About Industrial Tunnel Microwave Oven Jasmine Flower Dryer Machine

Introduction to Industrial Tunnel Microwave Ovens

Industrial Tunnel Microwave Ovens are revolutionizing the food processing industry by providing efficient, uniform, and rapid heating solutions. These ovens utilize microwave energy to heat products continuously as they pass through a tunnel, making them ideal for high-volume production lines. The uniform heating capability ensures that food products are processed evenly, reducing the risk of overcooking or under cooking, which is critical for maintaining product quality and safety.

One of the significant advantages of using an Industrial Tunnel Microwave Oven is its ability to significantly reduce processing times compared to conventional thermal methods. The rapid heating is particularly beneficial for sensitive products that can lose quality or nutritional value when exposed to prolonged heat. This efficiency not only improves productivity but also enhances the overall quality of the final product, making it more appealing to consumers and reducing waste.

Key Features of Industrial Tunnel Microwave Ovens

Industrial Tunnel Microwave Ovens are critical in modern food processing for their efficiency and versatility. Below, we highlight the key features that make these machines indispensable.

Feature | Description |

High Efficiency | Utilizes microwave technology to heat products quickly and uniformly, reducing processing time. |

Consistent Quality | Ensures even heating, maintaining product integrity and quality across batches. |

Energy Savings | More energy-efficient than conventional heating methods, leading to cost savings. |

Automation Capabilities | Can be integrated with automated systems for continuous production and minimal human intervention. |

Versatility | Suitable for a wide range of food products, including drying, heating, and sterilizing. |

Compact Design | Occupies less floor space compared to other industrial food processing equipment. |

Enhanced Control Systems | Equipped with advanced control panels for precise temperature and process management. |

Safety Features | Includes safety interlocks and emergency stop mechanisms to ensure safe operation. |

Hygienic Design | Constructed with food-grade materials and designed for easy cleaning and maintenance. |

Environmental Benefits | Lower emissions and reduced environmental impact compared to traditional heating methods. |

Combining with Jasmine Flower Dryer Machine

Combining an Industrial Tunnel Microwave Oven with a Jasmine Flower Dryer Machine offers significant advantages for food processors. This combination enhances drying efficiency and product quality while maintaining the delicate properties of jasmine flowers. The integrated system ensures that the drying process is fast, energy-efficient, and maintains the aroma and active ingredients of the flowers, making it ideal for producing high-quality dried jasmine products.

Industrial Tunnel Microwave Oven and Jasmine Flower Dryer Machine are crucial for modern food processing, providing high efficiency, consistent quality, and numerous operational benefits. Their advanced features and compatibility make them essential in the industry, ensuring optimal processing and superior end products.

Benefits of Using Industrial Tunnel Microwave Ovens

Industrial Tunnel Microwave Ovens offer numerous advantages in the food processing industry. They are designed to enhance efficiency, reduce processing times, and improve product quality. This article explores the key benefits of these advanced machines.

Benefit | Description |

Increased Efficiency | Industrial Tunnel Microwave Ovens can process large quantities of food quickly, leading to higher throughput and productivity. |

Uniform Heating | These ovens provide consistent and uniform heating, ensuring that food products are cooked or dried evenly. |

Energy Savings | Compared to traditional methods, microwave ovens are more energy-efficient, reducing operational costs. |

Improved Product Quality | The precise control of heating parameters helps maintain the nutritional value, flavor, and texture of food products. |

Faster Processing Times | Microwave technology significantly reduces processing times, enhancing overall production speed. |

Reduced Footprint | Industrial Tunnel Microwave Ovens require less space compared to conventional ovens, making them ideal for facilities with limited space. |

Versatility | These ovens can be used for a wide range of applications, including cooking, drying, and sterilizing various food products. |

Enhanced Safety | Modern microwave ovens incorporate advanced safety features, minimizing the risk of accidents and ensuring safe operation. |

Automation and Control | Equipped with sophisticated control systems, these ovens allow for precise monitoring and adjustment of processing parameters. |

Environmental Benefits | The reduced energy consumption and lower emissions contribute to a more sustainable food processing operation. |

Incorporating Industrial Tunnel Microwave Ovens into food processing operations can lead to significant improvements in efficiency, product quality, and overall cost-effectiveness. Additionally, combining these ovens with a Jasmine Flower Dryer Machine can further enhance the processing of specific products like jasmine flowers, ensuring optimal drying and preservation of delicate flavors and aromas. The use of Industrial Tunnel Microwave Oven Jasmine Flower Dryer Machine is thus highly beneficial for the food industry.

Understanding Jasmine Flower Dryer Machines

Jasmine flower dryer machines are specialized equipment used in the food industry to dry jasmine flowers efficiently. These machines are crucial for maintaining the delicate aroma and quality of jasmine flowers during the drying process.

Benefit | Explanation |

Preserves Aroma | Maintains the natural fragrance of jasmine flowers |

Consistent Quality | Ensures uniform drying, resulting in high-quality dried flowers |

Time Efficiency | Significantly reduces the drying time compared to traditional methods |

Energy Efficiency | Designed to use energy efficiently, reducing operational costs |

Automation Capability | Many machines offer automated processes, reducing the need for constant supervision |

Combining with Industrial Tunnel Microwave Ovens

Industrial tunnel microwave ovens can be integrated with jasmine flower dryer machines to enhance drying efficiency. The combination allows for rapid and uniform drying, preserving the delicate properties of jasmine flowers.

Advantage | Description |

Faster Drying Time | Microwave ovens speed up the drying process |

Enhanced Quality | Maintains better quality and aroma of jasmine flowers |

Reduced Energy Consumption | Combined systems are often more energy-efficient |

Increased Throughput | Higher processing capacity for large-scale operations |

Understanding the components and benefits of jasmine flower dryer machines is essential for optimizing the drying process in the food industry. By integrating these machines with industrial tunnel microwave ovens, businesses can achieve superior drying results, ensuring high-quality jasmine flowers with preserved aroma and consistency. Utilizing both Industrial Tunnel Microwave Oven and Jasmine Flower Dryer Machine technology, industries can significantly improve their drying efficiency and product quality.

Key Components of Jasmine Flower Dryer Machines

Understanding the key components of Jasmine Flower Dryer Machines is crucial for optimizing their performance and ensuring the quality of the dried flowers. Below is a detailed table outlining the essential parts of these machines, focusing on their role and importance in the drying process.

Component | Description |

Industrial Tunnel Microwave Oven | Utilizes microwave energy for efficient drying, significantly reducing drying time and preserving the flower's essential qualities. |

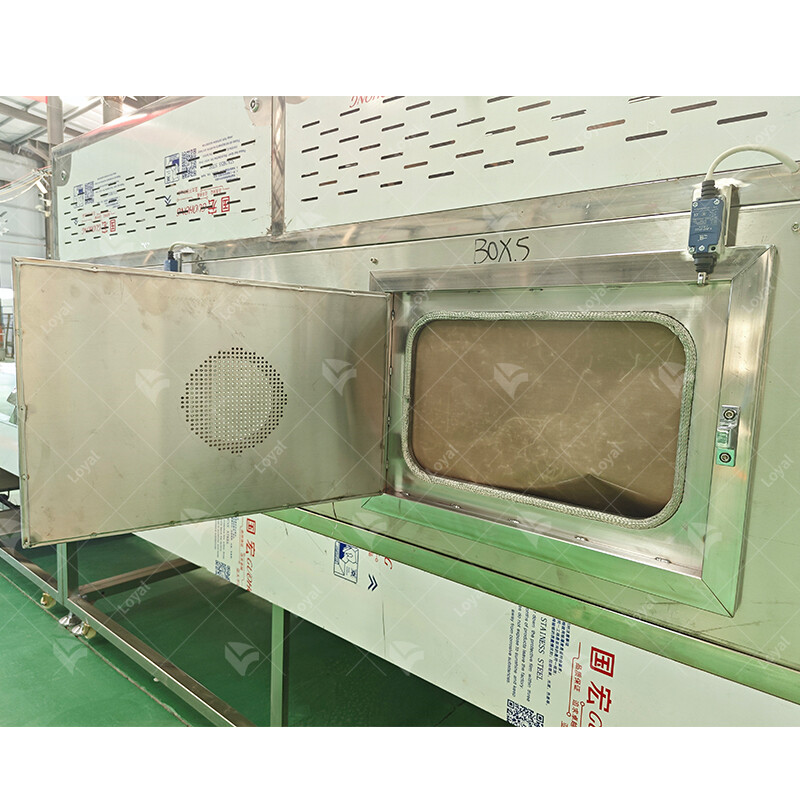

Drying Chamber | Enclosed space where jasmine flowers are placed for drying, ensuring uniform exposure to microwave energy. |

Conveyor Belt | Transports jasmine flowers through the drying chamber at a controlled speed to ensure even drying. |

Temperature Control System | Maintains the optimal temperature within the drying chamber to prevent overheating and preserve flower quality. |

Humidity Control System | Regulates moisture levels to ensure efficient drying without damaging the delicate flowers. |

Microwave Generator | Produces the microwave energy required for the drying process, a crucial part of the Industrial Tunnel Microwave Oven. |

Ventilation System | Removes excess moisture from the drying chamber to maintain a balanced environment. |

Control Panel | Allows operators to monitor and adjust drying parameters, ensuring precise control over the process. |

Safety Sensors | Detects any abnormalities in the system to prevent accidents and ensure safe operation. |

Energy Efficiency System | Optimizes energy use, making the drying process more sustainable and cost-effective. |

Each component of the Jasmine Flower Dryer Machine plays a vital role in ensuring that the drying process is efficient, safe, and preserves the quality of the jasmine flowers. The integration of an Industrial Tunnel Microwave Oven within these machines significantly enhances their performance by providing quick and uniform drying, which is essential for maintaining the delicate aroma and properties of jasmine flowers.

Advantages of Jasmine Flower Dryer Machines in Food Processing

Jasmine flower dryer machines, especially when integrated with advanced technologies like the industrial tunnel microwave oven, offer numerous benefits in the food processing industry. Below, we explore these advantages in detail.

Enhanced Drying Efficiency

Benefit | Description | |||

Speed | Faster drying times compared to traditional methods | |||

Uniformity | Even drying, preventing over-drying or under-drying | |||

Energy Efficiency | Reduced energy consumption due to advanced technology | |||

Aroma | Maintains the natural fragrance of jasmine flowers | |||

Nutrients | Retains essential nutrients and active compounds | |||

Appearance | Preserves the color and structure of the flowers | |||

Automation | Easy integration with automated production lines | |||

Scalability | Suitable for both small-scale and large-scale operations | |||

Flexibility | Adaptable to different flower types and food products | |||

Labor | Reduces labor costs with automated processes | |||

Maintenance | Lower maintenance costs due to durable equipment | |||

Yield | Increases overall yield with minimal waste | |||

The Industrial Tunnel Microwave Oven Jasmine Flower Dryer Machine stands out due to its innovative design and capability to enhance efficiency and product quality. This machine is crucial for businesses looking to improve their drying processes and achieve better consistency and quality in their final products.

Combining Industrial Tunnel Microwave Ovens with Jasmine Flower Dryers

Industrial Tunnel Microwave Ovens and Jasmine Flower Dryer Machines are essential components in the food processing industry, particularly for drying and preserving delicate flowers like jasmine. By integrating these two technologies, manufacturers can achieve efficient and high-quality drying results. This combination leverages the strengths of both machines to optimize the drying process.

Benefit | Description |

Efficiency | Industrial Tunnel Microwave Ovens provide rapid, uniform drying, reducing processing time. |

Quality Preservation | Jasmine Flower Dryer Machines ensure that the delicate structure and aroma of jasmine are maintained. |

Energy Savings | The combined use of microwave and traditional drying methods can reduce energy consumption. |

Consistency | Uniform drying ensures consistent product quality, essential for commercial success. |

Combining Industrial Tunnel Microwave Ovens with Jasmine Flower Dryer Machines offers significant advantages in the food processing industry. This integration results in efficient, high-quality drying that preserves the delicate nature of jasmine flowers. Manufacturers looking to improve their drying processes should consider this powerful combination to enhance their production capabilities.

Maintenance Tips for Industrial Tunnel Microwave Ovens and Flower Dryers

Proper maintenance of industrial food processing machinery is crucial for ensuring efficiency, safety, and longevity. This guide provides essential maintenance tips for two key pieces of equipment: the Industrial Tunnel Microwave Oven and the Jasmine Flower Dryer Machine. By following these guidelines, you can keep your equipment in optimal condition, reduce downtime, and ensure consistent product quality.

Regular Cleaning and Inspection

Maintenance Task | Frequency | Description |

Surface Cleaning | Daily | Wipe down all accessible surfaces with a damp cloth and mild detergent. |

Interior Inspection | Weekly | Check for any food residue, damage, or signs of wear inside the oven. |

Ventilation Cleaning | Monthly | Remove and clean the ventilation grates to ensure proper airflow. |

Conveyor Belt Check | Monthly | Inspect the conveyor belt for any wear and clean it thoroughly. |

Maintenance Task | Frequency | Description |

Surface Cleaning | Daily | Wipe down the machine with a soft cloth and suitable cleaning solution. |

Drying Chamber Check | Weekly | Inspect the drying chamber for any debris or residue. |

Filter Cleaning | Monthly | Clean or replace filters to maintain air quality and drying efficiency. |

Fan and Motor Inspection | Monthly | Ensure fans and motors are free of obstructions and operating smoothly. |

Maintenance Task | Frequency | Description |

Conveyor Belt Lubrication | Bi-monthly | Apply appropriate lubricant to the conveyor belt mechanisms. |

Mechanical Parts Inspection | Quarterly | Check all moving parts for wear and lubricate as needed. |

Door Seal Inspection | Quarterly | Ensure door seals are intact and replace if damaged to prevent heat loss. |

Maintenance Task | Frequency | Description |

Motor Lubrication | Bi-monthly | Lubricate motor bearings to ensure smooth operation. |

Belt and Pulley Check | Quarterly | Inspect and adjust belts and pulleys to maintain proper tension. |

Electrical Connections | Quarterly | Check all electrical connections for signs of wear or corrosion. |

Maintenance Task | Frequency | Description |

Safety Interlock Testing | Monthly | Test safety interlocks to ensure they are functioning correctly. |

Temperature Calibration | Quarterly | Verify temperature settings and recalibrate if necessary. |

Emergency Stop Functionality | Quarterly | Check that emergency stop buttons are accessible and working properly. |

By following these maintenance tips, you can ensure that your Industrial Tunnel Microwave Oven and Jasmine Flower Dryer Machine operate efficiently and reliably. Regular upkeep not only extends the lifespan of your equipment but also helps maintain high standards of food safety and quality.

Case Studies: Success Stories with Jasmine Flower Dryer Machines

In recent years, the adoption of the Industrial Tunnel Microwave Oven Jasmine Flower Dryer Machine has revolutionized the food processing industry. A leading example is seen in the operations of a prominent tea manufacturer in China, who reported a significant improvement in drying efficiency and product quality. By utilizing the industrial Tunnel Microwave Oven Jasmine Flower Dryer Machine, they managed to reduce drying time by 50% while maintaining the delicate aroma and medicinal properties of jasmine flowers. This technology allowed for a consistent and gentle drying process, preserving the flowers' natural essence and enhancing the overall quality of their jasmine tea products.

Another remarkable case comes from a European herbal product company that integrated the Industrial Tunnel Microwave Oven Jasmine Flower Dryer Machine into their production line. Prior to this, the company faced challenges in maintaining uniform quality across batches, resulting in significant product loss. With the implementation of the microwave drying technology, they achieved a 40% increase in production efficiency. The uniform heat distribution provided by the tunnel microwave oven ensured that every batch of jasmine flowers was dried evenly, minimizing wastage and enhancing the consistency of their herbal products.

Lastly, an organic skincare company in North America also reaped substantial benefits from adopting the Industrial Tunnel Microwave Oven Jasmine Flower Dryer Machine They previously struggled with lengthy drying processes that compromised the freshness and potency of their ingredients. By switching to the advanced microwave drying system, they experienced a 60% reduction in processing time. This not only sped up their production but also retained the vibrant color and beneficial properties of the jasmine flowers used in their skincare line, resulting in a superior product that stood out in the market.

These case studies illustrate the significant advantages and success stories associated with the Industrial Tunnel Microwave Oven Jasmine Flower Dryer Machine. Its ability to enhance efficiency, maintain product quality, and reduce wastage has made it a valuable asset in various sectors of the food and wellness industries.

Reference

The following are five authoritative foreign literature websites in the field of industrial microwaves:

1. IEEE Xplore Digital Library

Website: https://ieeexplore.ieee.org/

2.ScienceDirect

Website: https://www.sciencedirect.com/

3. SpringerLink

Website: https://link.springer.com/

4. Wiley Online Library

Website: https://onlinelibrary.wiley.com/

5. PubMed

Website: https://pubmed.ncbi.nlm.nih.gov/

Telephone :+86-531-55583139

Telephone :+86-531-55583139 WhatsApp :+86 13256674591

WhatsApp :+86 13256674591 Email :

Email :