Everything you need to know about industrial tunnel microwave bread crumb nutrition powder sterilizing machine in 2024

Introduction to Industrial Tunnel Microwave Bread Crumb Nutrition Powder Sterilizing Machine

In the ever-evolving landscape of industrial food processing, the utilization of advanced machinery plays a pivotal role in ensuring efficiency, quality, and safety. Among these innovative machines, the industrial tunnel microwave bread crumb nutrition powder sterilizing machine stands out for its remarkable capabilities in enhancing food processing operations.

This introduction aims to shed light on the significance of this specialized equipment in the food processing industry, particularly in sterilizing bread crumbs and nutrition powder. By harnessing the power of microwave technology, this machine revolutionizes the sterilization process, ensuring the elimination of harmful pathogens while preserving the nutritional integrity of the food products.

Microwave technology, renowned for its rapid and uniform heating properties, serves as the cornerstone of the sterilization process carried out by this machine. Unlike conventional methods that rely on heat transfer through conduction or convection, microwave technology penetrates the entire product, effectively sterilizing it from within.

The introduction of the industrial tunnel microwave bread crumb nutrition powder sterilizing machine marks a significant advancement in food processing technology, offering manufacturers a reliable and efficient solution to meet stringent food safety standards and consumer demands.

Operational Mechanism of Industrial Tunnel Microwave Bread Crumb Nutrition Powder Sterilizing Machine

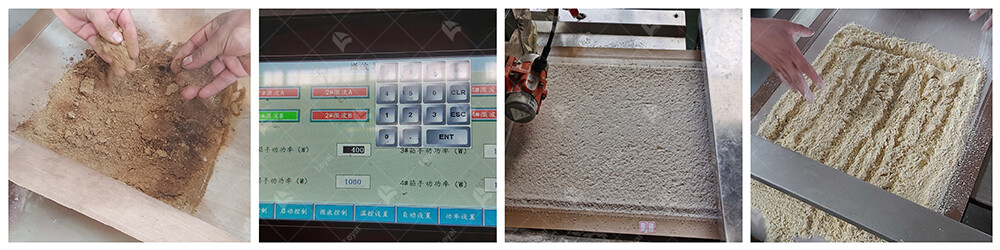

The industrial tunnel microwave bread crumb nutrition powder sterilizing machine operates on a sophisticated mechanism that harnesses the power of microwave technology for efficient sterilization. Below is a detailed breakdown of its operational process:

1. Utilization of Microwave Technology:

The machine employs microwave radiation to generate heat within the sterilization chamber. Microwaves are electromagnetic waves that penetrate the bread crumbs and nutrition powder, causing the water molecules within the food particles to vibrate rapidly. This agitation generates heat, effectively sterilizing the products.

2. Components and Functions:

Tunnel Conveyor System: The sterilization chamber consists of a conveyor belt system that transports the bread crumbs and nutrition powder through the microwave field at a controlled speed. This ensures uniform exposure to microwave radiation for thorough sterilization.

Microwave Generator: A powerful microwave generator emits microwave radiation into the sterilization chamber, creating a high-intensity electromagnetic field. The frequency and power output of the microwave generator are carefully calibrated to achieve optimal sterilization results.

Temperature Control Mechanisms: The machine is equipped with temperature sensors and control mechanisms to monitor and regulate the internal temperature of the sterilization chamber. This ensures that the bread crumbs and nutrition powder are subjected to the precise level of heat required for effective sterilization while preventing overheating or undercooking.

3. Efficiency and Effectiveness:

The use of microwave technology offers several advantages in sterilizing bread crumbs and nutrition powder. It provides rapid and uniform heating, resulting in shorter processing times and increased production throughput.

Microwave sterilization also preserves the nutritional content and sensory qualities of the food products better than traditional sterilization methods such as heat treatment or chemical additives.

Additionally, microwave sterilization is a chemical-free process, eliminating the need for preservatives or additives, and reducing the risk of contamination or alteration of the product's flavor and texture.

Applications and Industries Implementing Industrial Tunnel Microwave Bread Crumb Nutrition Powder Sterilizing Machine

Industrial tunnel microwave bread crumb nutrition powder sterilizing machines find widespread application across various food processing industries due to their efficiency and effectiveness in sterilization processes. Here's a brief overview of the industries and applications where these machines are commonly implemented:

1. Bakery Industry:

In the bakery industry, industrial tunnel microwave sterilizing machines are utilized for sterilizing bread crumbs, ensuring they are free from harmful microorganisms while preserving their texture and flavor.

These machines play a crucial role in maintaining the quality and safety of bread products, including breaded meats, poultry, seafood, and snacks.

2. Nutritional Supplement Manufacturing:

Industrial microwave sterilizing machines are also integral to the production of nutritional supplements and powdered food ingredients.

These machines effectively sterilize nutrition powders, vitamins, and mineral supplements, ensuring they meet stringent quality and safety standards.

3. Powdered Food Processing:

The machine is extensively used in the processing of powdered food ingredients such as flour, starch, and protein powders.

By sterilizing these ingredients, the machine helps prevent microbial contamination and extends the shelf life of powdered food products.

4. Ready-to-Eat Meal Manufacturing:

Manufacturers of ready-to-eat meals utilize industrial tunnel microwave sterilizing machines to sterilize bread crumbs used in meal preparations.

These machines ensure the safety and hygiene of ready-to-eat meals, enhancing their shelf life and maintaining their quality during storage and distribution.

5. Snack Food Production:

Industrial microwave sterilizing machines are employed in the production of snack foods such as coated nuts, chips, and extruded snacks.

By sterilizing bread crumbs and nutritional powders used in snack formulations, these machines contribute to the overall safety and quality of snack products.

Advantages and Benefits of Industrial Tunnel Microwave Bread Crumb Nutrition Powder Sterilizing Machine

Advantage | Explanation |

Rapid Sterilization | - The industrial tunnel microwave bread crumb nutrition powder sterilizing machine offers rapid sterilization, significantly reducing processing time compared to traditional methods. |

Preservation of Nutritional Value | - Microwave technology enables gentle sterilization, preserving the nutritional value of bread crumbs and nutrition powder by minimizing heat exposure. |

Energy Efficiency | - The machine operates with high energy efficiency, utilizing microwave technology to generate heat directly within the product, minimizing energy wastage. |

Maintaining Product Quality and Safety | - Microwave sterilization ensures uniform heating throughout the product, effectively eliminating pathogens while maintaining product quality, texture, and taste. |

Superiority Over Traditional Methods | - Compared to traditional sterilization methods such as hot air or steam, microwave technology offers superior efficiency, precision, and control over the sterilization process. |

Technical parameters

| Technical Parameters Of Continuous Microwave Dryer Industrial Microwave Drying Machine | |||||

| Model | Size LWH(Can be customized according to the customer's requirements) | Output power | Dewaterability | Sterilization capacity | Baking and Roasting capacity (Depends on different raw material) |

| LY-10KW | 5000mm825mm1750mm | ≥10KW | 10KG/Hour | 100KG/Hour | 30-50KG/Hour |

| LY-20KW | 8000mm825mm1750mm | ≥20KW | 20KG/Hour | 200KG/Hour | 60-100KG/Hour |

| LY-30KW | 8500mm1160mm1750mm | ≥30KW | 30KG/Hour | 300KG/Hour | 90-150 KG/Hour |

| LY-40KW | 10000mm1160mm1750mm | ≥40KW | 40KG/Hour | 40KG/Hour | 120-200KG/Hour |

| LY-50KW | 12500mm1160mm1750mm | ≥50KW | 50KG/Hour | 500KG/Hour | 150-250KG/Hour |

| LY-60KW | 13500mm1450mm1750mm | ≥60KW | 60KG/Hour | 600KG/Hour | 180-300KG/Hour |

| LY-70KW | 13500mm1500mm1750mm | ≥70KW | 70KG/Hour | 700KG/Hour | 210-350KG/Hour |

| LY-80KW | 13500mm1650mm1750mm | ≥80KW | 80KG/Hour | 800KG/Hour | 240-400KG/Hour |

| LY-100KW | 16800mm1650mm1750mm | ≥100KW | 100KG/Hour | 1000KG/Hour | 300-500KG/Hour |

| LY-150KW | 22400mm1850mm1750mm | ≥150KW | 150KG/Hour | 1500KG/Hour | 450-750KG/Hour |

| LY-200KW | 27000mm1850mm1750mm | ≥250KW | 250KG/Hour | 2500KG/Hour | 750-1250/Hour |

| LY-300KW | 32000mm1850mm1750mm | ≥300KW | 300KG/Hour | 3000KG/Hour | 900-1500KG/Hour |

| Power Supply | 380V±10% 50Hz±1% Three-Phase Five-Wire | ||||

| Microwave Output Frequency | 2450±50Mhz | ||||

| Microwave Input Apparent Power | ≤168Kva | ||||

| Microwave Output Power | ≥120Kw | ||||

| Microwave Power Adjustment Range | 0-30Kw(Adjustable) | ||||

| Ambient Temperature | -5-40°C | ||||

| Relative Humidity | ≤80%, Surrounding Environment:No Corrosive Gas, Conductive Dust And Explosive Gas | ||||

| Transmission Speed | 0-10m/Min(Adjustable) | ||||

Maintenance and Care of Industrial Tunnel Microwave Bread Crumb Nutrition Powder Sterilizing Machine

Maintaining and caring for an industrial tunnel microwave bread crumb nutrition powder sterilizing machine is crucial for ensuring its optimal performance and longevity. Here's a detailed guide on the necessary maintenance procedures:

Regular Maintenance Procedures:

Regular maintenance is essential to keep the machine running smoothly and efficiently. This includes:

1. Cleaning:

Regularly clean the interior and exterior of the machine to remove any food residues, grease, or dirt buildup.

Pay special attention to the conveyor system, microwave chambers, and other critical components to prevent contamination and ensure hygiene standards.

2. Calibration:

Periodically calibrate the machine to ensure accurate temperature and power settings.

Calibration helps maintain consistent sterilization results and prevents over-processing or under-processing of bread crumbs and nutrition powder.

3. Inspection:

Conduct routine inspections of the machine's components, including seals, belts, bearings, and electrical connections.

Look for signs of wear and tear, damage, or malfunctioning parts that may affect the machine's performance.

Troubleshooting Guidelines:

In case of any issues or malfunctions, follow these troubleshooting guidelines:

1. Identify the Problem:

Diagnose the problem by observing any abnormal sounds, smells, or performance issues with the machine.

Consult the user manual or contact the manufacturer for troubleshooting guidance.

2. Perform Repairs:

If the issue is minor, perform necessary repairs or adjustments following the manufacturer's instructions.

For major repairs or component replacements, seek assistance from qualified technicians or service providers.

Safety Compliance and Documentation Practices:

Ensuring safety compliance and maintaining proper documentation is essential for regulatory compliance and quality assurance:

1. Safety Compliance:

Adhere to all safety guidelines and regulations while operating and maintaining the machine.

Provide proper training to operators on safe machine handling and emergency procedures.

2. Documentation:

Maintain detailed records of maintenance activities, including cleaning schedules, calibration logs, and repair records.

Keep track of any modifications or upgrades made to the machine for traceability and quality control purposes.

By following these maintenance and care guidelines, operators can ensure the reliable performance and longevity of the industrial tunnel microwave bread crumb nutrition powder sterilizing machine, contributing to efficient food processing operations and product quality assurance.

Future Trends and Developments

In the realm of industrial food processing, particularly concerning the sterilization of bread crumbs and nutrition powder, there are several emerging trends and developments worth exploring. Let's delve into these future advancements in industrial tunnel microwave bread crumb nutrition powder sterilizing machines:

1. Integration of Smart Technologies:

- As technology continues to advance, there is a growing trend towards the integration of smart technologies in industrial food processing equipment, including microwave sterilizing machines.

- These smart features may include real-time monitoring and control systems, predictive maintenance capabilities, and remote operation functionalities.

- The incorporation of smart technologies aims to enhance efficiency, optimize resource utilization, and ensure consistent sterilization performance.

2. Enhanced Sterilization Efficiency:

- Future developments in industrial tunnel microwave sterilizing machines are expected to focus on further improving sterilization efficiency and effectiveness.

- This may involve advancements in microwave heating technology, such as the development of innovative cavity designs and optimized energy distribution systems.

- The goal is to achieve faster processing times, higher throughput rates, and superior microbial reduction while maintaining product quality and nutritional integrity.

3. Customization and Flexibility:

- With increasing consumer demand for customized food products, future industrial sterilizing machines are likely to offer greater flexibility and customization options.

- Manufacturers may develop modular machine configurations that can be easily adapted to accommodate different product types, sizes, and processing requirements.

- This flexibility enables food producers to respond quickly to changing market demands and offer a diverse range of sterilized bread crumbs and nutrition powder products.

4. Sustainability and Environmental Considerations:

- In line with global sustainability initiatives, future developments in industrial sterilizing machines are expected to prioritize energy efficiency and environmental sustainability.

- Manufacturers may incorporate eco-friendly materials, energy-saving technologies, and recycling systems into machine designs to minimize environmental impact.

- Additionally, there may be a focus on reducing water usage, waste generation, and carbon emissions throughout the sterilization process.

5. Integration of Artificial Intelligence (AI) and Machine Learning:

- AI and machine learning technologies hold great potential for optimizing the operation and performance of industrial sterilizing machines.

- These technologies can analyze vast amounts of data to identify patterns, optimize sterilization parameters, and predict equipment maintenance needs.

- By harnessing the power of AI, manufacturers can enhance productivity, quality control, and operational efficiency in food processing facilities.

6. Expansion into New Markets and Applications:

- As consumer preferences evolve and new food trends emerge, there is a growing opportunity for industrial sterilizing machines to expand into new markets and applications.

- Manufacturers may develop specialized machines tailored to specific food products or niche markets, such as gluten-free or organic foods.

- This diversification allows food producers to capitalize on emerging trends and tap into new revenue streams in the rapidly evolving food industry landscape.

Conclusion

In 2024, the industrial tunnel microwave bread crumb nutrition powder sterilizing machine stands as a pivotal advancement in food processing technology. Throughout this guide, we have delved into its significance and highlighted key aspects essential for understanding its importance.

The industrial tunnel microwave bread crumb nutrition powder sterilizing machine represents a paradigm shift in the food processing industry. Its ability to utilize microwave technology for sterilization ensures rapid and efficient treatment of bread crumbs and nutrition powder, safeguarding their quality and safety. This machine addresses the pressing need for advanced sterilization methods in industrial settings, where large-scale production demands reliability, speed, and effectiveness.

Throughout this guide, we explored various aspects of the industrial tunnel microwave bread crumb nutrition powder sterilizing machine. We examined its operational mechanism, applications across different industries, advantages over traditional methods, and the importance of maintenance. Additionally, we discussed future trends and developments, highlighting the continuous evolution of food processing technology to meet the demands of the ever-changing market landscape.

In conclusion, the adoption of advanced food processing technologies such as the industrial tunnel microwave bread crumb nutrition powder sterilizing machine is paramount for enhancing efficiency, product quality, and food safety in the bread crumb and nutrition powder industry. By embracing innovation and investing in cutting-edge equipment, food manufacturers can ensure the production of high-quality, safe, and nutritious products that meet consumer expectations and regulatory standards. As we move forward, continued research and development in food processing technology will further propel the industry towards greater heights of excellence and sustainability.

References

The following are five authoritative foreign literature websites in the field of industrial microwaves:

1. IEEE Xplore Digital Library

Website: [https://ieeexplore.ieee.org/]

2.ScienceDirect

Website: [https://www.sciencedirect.com/]

3. SpringerLink

Website: [https://link.springer.com/]

4. Wiley Online Library

Website: [https://onlinelibrary.wiley.com/]

5. PubMed

Website: [https://pubmed.ncbi.nlm.nih.gov/]

Telephone :+86-531-55583139

Telephone :+86-531-55583139 WhatsApp :+86 13256674591

WhatsApp :+86 13256674591 Email :

Email :