Everything you need to know about Industrial Tunnel Microwave Balck Tea Powder Sterilization Sterilizer Equipment In 2024

Introduction

In 2024, the utilization of industrial tunnel microwave black tea powder sterilization sterilizer equipment represents a significant advancement in the tea industry. This cutting-edge equipment leverages microwave technology to enhance the sterilization process for black tea powder, ensuring superior quality and safety standards.

Traditionally, the sterilization of tea powder has been achieved through conventional methods such as steam or heat treatment. However, with the introduction of industrial tunnel microwave sterilizer equipment, the process has been revolutionized, offering numerous advantages in terms of efficiency, effectiveness, and product quality.

In this comprehensive guide, we will explore the functionalities, benefits, applications, and considerations of industrial tunnel microwave black tea powder sterilization sterilizer equipment. By understanding the intricacies of this innovative technology, stakeholders in the tea industry can capitalize on its potential to elevate the standards of black tea powder processing in 2024 and beyond.

Working Principle

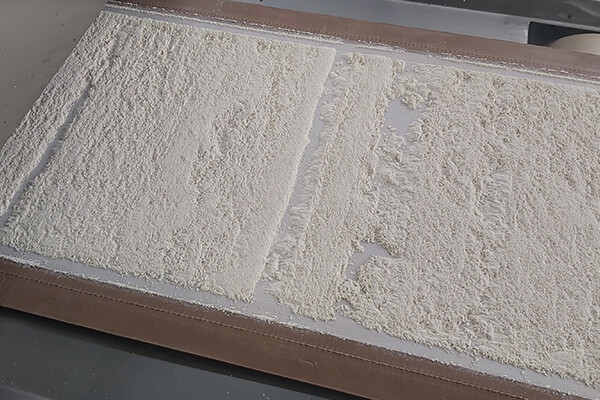

The basic principle of the industrial tunnel microwave black tea powder sterilization equipment is to sterilize black tea powder using microwave energy in an industrial environment. This advanced equipment uses the unique properties of microwaves to achieve rapid and effective sterilization, ensuring the safety and quality of the final product. The working principle of microwave sterilization is to expose black tea powder to electromagnetic waves in a tunnel-shaped chamber. These waves penetrate the powder, causing the water molecules in the tea to vibrate rapidly. The result is friction and heat, which causes the temperature of the entire powder to increase. The increased temperature effectively kills harmful microorganisms present in the black tea powder, including bacteria, viruses and fungi. Unlike traditional sterilization methods such as steam or chemical treatment, microwave sterilization has several advantages, including shorter processing time, uniform heating and minimal nutrient loss. The industrial tunnel microwave black tea powder sterilization equipment is equipped with precise controls that can adjust the power and duration of microwave irradiation to ensure consistent and thorough sterilization while minimizing the risk of over-processing. In addition, the tunnel design allows for the continuous processing of large batches of black tea powder, making it ideal for industrial-scale production. In summary, the working principle of the industrial tunnel microwave black tea powder sterilization equipment is rooted in the efficient use of microwave energy to achieve rapid and effective sterilization of black tea powder. This innovative technology provides a reliable solution for ensuring the safety and quality of black tea products in the modern tea industry.

Advantages of industrial tunnel microwave black tea powder sterilization equipment

1. Rapid Sterilization: |

- Utilizes microwave technology for quick and efficient sterilization process. |

- Significantly reduces processing time compared to conventional methods. |

2. Uniform Heating: |

- Ensures uniform heating throughout the tea powder, eliminating cold spots. |

- Prevents overheating or underheating, maintaining product quality. |

3. Preservation of Nutritional Value: |

- Gentle sterilization process preserves the nutritional integrity of tea powder. |

- Retains vitamins, antioxidants, and other beneficial compounds. |

4. Chemical-Free Sterilization: |

- Eliminates the need for chemical additives or preservatives. |

- Ensures the safety and purity of the tea powder product. |

5. Energy-Efficient: |

- Microwave technology consumes less energy compared to traditional methods. |

- Reduces operating costs and environmental impact. |

6. Scalability: |

- Suitable for large-scale production due to its industrial tunnel design. |

- Can accommodate high volumes of tea powder efficiently. |

7. Versatility: |

- Can be customized to sterilize various types of tea powders and other products. |

- Offers flexibility to adapt to different processing requirements. |

8. Minimal Labor Requirement: |

- Automated operation reduces the need for manual intervention. |

- Streamlines production processes and increases efficiency. |

9. Compliance with Food Safety Standards: |

- Meets regulatory requirements for food safety and hygiene. |

- Ensures compliance with industry standards and regulations. |

10. Improved Shelf Life: |

- Extends the shelf life of tea powder by eliminating spoilage-causing organisms. |

- Enhances product freshness and longevity. |

Key components of industrial microwave ovens

Component | Description |

Magnetron | The magnetron generates microwave radiation by converting electrical energy into electromagnetic waves. It is the core component responsible for producing the microwaves used for heating. |

Waveguide | The waveguide is a metal tube or channel that directs the microwave radiation from the magnetron into the oven cavity. It ensures that the microwaves are distributed evenly throughout the cavity for uniform heating. |

Stirrer Fan | The stirrer fan is a rotating device located inside the oven cavity. It helps to disperse the microwave energy evenly, preventing hot spots and ensuring uniform heating of the food or material being processed. |

Control Panel | The control panel houses the user interface and controls of the microwave oven. It allows operators to set parameters such as temperature, power level, and processing time. Some advanced models may feature touchscreen interfaces for easier operation. |

Temperature Sensor | Industrial microwave ovens are equipped with temperature sensors to monitor the internal temperature of the oven cavity. These sensors ensure that the desired temperature is maintained throughout the sterilization process. |

Safety Interlock | Safety interlocks are mechanisms designed to prevent the oven from operating if the door is not securely closed. This feature helps to protect operators from exposure to microwave radiation and ensures safe operation of the equipment. |

Technical parameters

| Technical Parameters Of Continuous Microwave Dryer Industrial Microwave Drying Machine | |||||

| Model | Size LWH(Can be customized according to the customer's requirements) | Output power | Dewaterability | Sterilization capacity | Baking and Roasting capacity (Depends on different raw material) |

| LY-10KW | 5000mm825mm1750mm | ≥10KW | 10KG/Hour | 100KG/Hour | 30-50KG/Hour |

| LY-20KW | 8000mm825mm1750mm | ≥20KW | 20KG/Hour | 200KG/Hour | 60-100KG/Hour |

| LY-30KW | 8500mm1160mm1750mm | ≥30KW | 30KG/Hour | 300KG/Hour | 90-150 KG/Hour |

| LY-40KW | 10000mm1160mm1750mm | ≥40KW | 40KG/Hour | 40KG/Hour | 120-200KG/Hour |

| LY-50KW | 12500mm1160mm1750mm | ≥50KW | 50KG/Hour | 500KG/Hour | 150-250KG/Hour |

| LY-60KW | 13500mm1450mm1750mm | ≥60KW | 60KG/Hour | 600KG/Hour | 180-300KG/Hour |

| LY-70KW | 13500mm1500mm1750mm | ≥70KW | 70KG/Hour | 700KG/Hour | 210-350KG/Hour |

| LY-80KW | 13500mm1650mm1750mm | ≥80KW | 80KG/Hour | 800KG/Hour | 240-400KG/Hour |

| LY-100KW | 16800mm1650mm1750mm | ≥100KW | 100KG/Hour | 1000KG/Hour | 300-500KG/Hour |

| LY-150KW | 22400mm1850mm1750mm | ≥150KW | 150KG/Hour | 1500KG/Hour | 450-750KG/Hour |

| LY-200KW | 27000mm1850mm1750mm | ≥250KW | 250KG/Hour | 2500KG/Hour | 750-1250/Hour |

| LY-300KW | 32000mm1850mm1750mm | ≥300KW | 300KG/Hour | 3000KG/Hour | 900-1500KG/Hour |

| Power Supply | 380V±10% 50Hz±1% Three-Phase Five-Wire | ||||

| Microwave Output Frequency | 2450±50Mhz | ||||

| Microwave Input Apparent Power | ≤168Kva | ||||

| Microwave Output Power | ≥120Kw | ||||

| Microwave Power Adjustment Range | 0-30Kw(Adjustable) | ||||

| Ambient Temperature | -5-40°C | ||||

| Relative Humidity | ≤80%, Surrounding Environment:No Corrosive Gas, Conductive Dust And Explosive Gas | ||||

| Transmission Speed | 0-10m/Min(Adjustable) | ||||

Application of Industrial Tunnel Microwave Black Tea Powder Sterilization Equipment

In 2024, the utilization of industrial tunnel microwave black tea powder sterilization equipment has become integral to the tea processing industry. This advanced technology offers a revolutionary approach to sterilizing black tea powder, ensuring safety, quality, and efficiency throughout the production process.

The industrial tunnel microwave black tea powder sterilization equipment operates on the principle of dielectric heating, where electromagnetic waves penetrate the tea powder, causing water molecules to vibrate rapidly and generate heat. This rapid heating effectively eliminates harmful microorganisms such as bacteria, molds, and fungi, while preserving the natural flavor, aroma, and nutritional properties of the tea.

One of the key advantages of using industrial tunnel microwave sterilization equipment is its ability to provide uniform and consistent sterilization throughout the tea powder. Unlike traditional methods such as steam or chemical sterilization, which may result in uneven heating and potential degradation of tea quality, microwave sterilization ensures thorough and precise treatment.

Furthermore, industrial tunnel microwave sterilization equipment offers significant time and cost savings compared to conventional sterilization methods. With its rapid processing capabilities, large quantities of tea powder can be sterilized efficiently, reducing production time and increasing overall productivity.

The application of industrial tunnel microwave black tea powder sterilization equipment extends across various sectors of the tea industry, including large-scale tea processing plants, tea packaging facilities, and tea product manufacturers. Its versatility and effectiveness make it a preferred choice for ensuring the safety and quality of black tea powder products.

Technological progress and innovation

Microwave technology has revolutionized the sterilization process, offering unparalleled efficiency and effectiveness in treating black tea powder. Unlike traditional methods, microwave sterilization utilizes electromagnetic waves to penetrate the tea particles, targeting and destroying harmful microorganisms without compromising the quality or flavor of the tea.

One of the key features of industrial tunnel microwave black tea powder sterilization sterilizer equipment is its ability to achieve uniform heating throughout the product. This ensures that every particle of tea powder receives the appropriate level of heat treatment, eliminating the risk of uneven sterilization and preserving the integrity of the final product.

Moreover, the use of microwave technology significantly reduces processing time compared to conventional methods. This not only enhances productivity but also minimizes energy consumption, making it a cost-effective solution for tea manufacturers.

Furthermore, industrial tunnel microwave sterilizers are equipped with advanced control systems that allow for precise adjustment of sterilization parameters such as temperature, humidity, and exposure time. This level of customization ensures optimal results tailored to the specific requirements of different tea varieties, guaranteeing consistency and quality in every batch.

In addition to its sterilization capabilities, industrial tunnel microwave equipment also offers versatility in application. Beyond black tea powder, it can be adapted to sterilize a wide range of food products, making it a valuable asset for food processing facilities seeking efficiency and reliability in their operations.

In conclusion, industrial tunnel microwave black tea powder sterilization sterilizer equipment represents a pinnacle of technological innovation in the food industry. Its ability to deliver fast, uniform, and precise sterilization while maintaining product quality makes it an indispensable tool for tea manufacturers striving for excellence in their processes. As we move forward into 2024 and beyond, we can expect further advancements in microwave technology to continue revolutionizing the way we approach food sterilization.

Precautions for the selection and implementation of industrial tunnel microwave black tea powder sterilization equipment

When considering the implementation of industrial tunnel microwave black tea powder sterilization equipment, several crucial factors warrant careful consideration. From selecting the appropriate equipment to ensuring seamless implementation, here are some expert recommendations to guide your decision-making process.

1. Equipment Selection:

Choosing the right industrial tunnel microwave black tea powder sterilization equipment is paramount to the success of your sterilization process. Prioritize models equipped with advanced microwave technology, specifically tailored to meet the requirements of black tea powder sterilization. Look for features such as precise temperature control, uniform heating capabilities, and efficient sterilization cycles.

2. Quality Assurance:

Ensure that the selected equipment complies with industry standards and regulations for food processing and sterilization. Quality certifications and endorsements from relevant authorities are indicative of a reliable and trustworthy sterilizer. Prioritize suppliers with a proven track record of delivering high-quality equipment and comprehensive after-sales support.

3. Operational Efficiency:

Opt for industrial tunnel microwave sterilization equipment that offers seamless integration into your existing production line. Consider factors such as footprint, throughput capacity, and energy efficiency to maximize operational efficiency while minimizing downtime. Collaborate closely with equipment suppliers to customize solutions tailored to your specific processing requirements.

4. Maintenance and Support:

Safeguard the long-term performance of your sterilization equipment by prioritizing regular maintenance and timely technical support. Establish a proactive maintenance schedule and invest in training programs to empower your workforce with the necessary skills for equipment upkeep. Partner with suppliers offering responsive customer support and readily available spare parts to mitigate operational disruptions.

5. Regulatory Compliance:

Stay abreast of evolving regulatory requirements governing food processing and sterilization practices. Ensure that your chosen sterilization equipment adheres to relevant safety and hygiene standards, mitigating potential risks associated with product contamination or non-compliance. Maintain comprehensive documentation of sterilization processes and equipment calibration to facilitate regulatory inspections and audits.

Challenges and limitations

In 2024, Industrial Tunnel Microwave Black Tea Powder Sterilization Sterilizer Equipment stands at the forefront of modern sterilization methods. This innovative technology revolutionizes the tea processing industry, ensuring the safety and quality of black tea powder for consumers worldwide. However, despite its numerous benefits, this equipment also encounters certain challenges and limitations.

One of the primary challenges associated with Industrial Tunnel Microwave Black Tea Powder Sterilization Sterilizer Equipment is the need for precise calibration and monitoring. Unlike traditional sterilization methods, such as steam or chemical treatment, microwave sterilization requires careful adjustment of power levels and exposure times to ensure effective sterilization while avoiding damage to the tea powder. This necessitates skilled technicians and advanced monitoring systems to maintain optimal operating conditions.

Another limitation of Industrial Tunnel Microwave Black Tea Powder Sterilization Sterilizer Equipment is its susceptibility to moisture content variations. Tea leaves naturally contain moisture, which can affect the efficiency of microwave sterilization. High moisture levels can lead to uneven heating and insufficient sterilization, while low moisture levels may result in excessive drying and loss of flavor. Achieving the ideal moisture balance is essential for consistent and high-quality sterilization results.

Furthermore, the scalability of Industrial Tunnel Microwave Black Tea Powder Sterilization Sterilizer Equipment poses a challenge for large-scale tea production facilities. While suitable for small to medium-sized operations, scaling up microwave sterilization processes to meet the demands of industrial-scale production requires significant investment in equipment and infrastructure. Additionally, the logistical challenges of integrating microwave sterilization into existing production lines can further complicate the implementation process.

Despite these challenges, ongoing research and development efforts continue to address the limitations of Industrial Tunnel Microwave Black Tea Powder Sterilization Sterilizer Equipment. Advancements in technology aim to improve precision, scalability, and efficiency, making microwave sterilization an increasingly viable option for the tea industry. By overcoming these challenges, Industrial Tunnel Microwave Black Tea Powder Sterilization Sterilizer Equipment promises to play a pivotal role in ensuring the safety and quality of black tea powder for years to come.

References

The following are five authoritative foreign literature websites in the field of industrial microwaves:

1. IEEE Xplore Digital Library

Website: [https://ieeexplore.ieee.org/]

2.ScienceDirect

Website: [https://www.sciencedirect.com/]

3. SpringerLink

Website: [https://link.springer.com/]

4. Wiley Online Library

Website: [https://onlinelibrary.wiley.com/]

5. PubMed

Website: [https://pubmed.ncbi.nlm.nih.gov/]

Telephone :+86-531-55583139

Telephone :+86-531-55583139 WhatsApp :+86 13256674591

WhatsApp :+86 13256674591 Email :

Email :