Everything you Need to Know About Industrial Microwave Food Egg Drying Machine

Overview of Industrial Microwave Food Egg Drying Machine

Industrial microwave food egg drying machines are essential equipment in the food processing industry, specifically designed to efficiently and effectively dry eggs for various purposes. These machines utilize microwave technology to remove moisture from eggs while preserving their nutritional value and extending their shelf life.

Microwave technology has revolutionized the food industry, offering fast and uniform heating capabilities compared to conventional drying methods. Industrial microwave food egg drying machines capitalize on these benefits, providing a reliable and cost-effective solution for egg processing plants.

Introduction to Microwave Technology in Food Industry

Microwave technology has gained widespread acceptance in the food industry due to its ability to quickly and evenly heat food products. In the context of egg drying, industrial microwave food egg drying machines utilize electromagnetic waves to penetrate the eggs, causing water molecules to vibrate and generate heat. This process results in rapid and efficient drying, reducing processing time and preserving the quality of the eggs.

Industrial microwave food egg drying machines consist of a chamber where eggs are placed on trays or conveyor belts. Microwave generators emit electromagnetic waves into the chamber, heating the eggs uniformly and facilitating the drying process. Advanced control systems ensure precise temperature and moisture control, optimizing drying efficiency and product quality.

Microwave technology offers several advantages over traditional drying methods, including shorter processing times, energy savings, and improved product quality. By harnessing the power of microwaves, industrial food egg drying machines can achieve higher throughput and enhance overall productivity in egg processing facilities.

Understanding the Importance of Drying in Food Preservation

Drying plays a crucial role in food preservation by removing moisture from food products, thereby inhibiting the growth of microorganisms and preventing spoilage. Industrial Microwave Food Egg Drying Machine utilizes microwave technology to effectively remove moisture from food items, including eggs, ensuring their long-term preservation.

One of the key benefits of drying in food preservation is the extension of shelf life. By reducing the moisture content in food products such as eggs, the growth of bacteria, mold, and yeast is inhibited, significantly prolonging their shelf life. Industrial Microwave Food Egg Drying Machines offer precise control over the drying process, allowing for optimal preservation of food quality and safety.

Additionally, drying helps to reduce the weight and volume of food products, making them more convenient for storage, transportation, and distribution. Industrial Microwave Food Egg Drying Machines efficiently remove moisture from eggs without compromising their nutritional value or sensory properties, ensuring that they remain a viable food source for longer periods.

Advantages of Using Industrial Microwave Drying Machines

Industrial Microwave Drying Machines offer numerous advantages over traditional drying methods, making them an ideal choice for food processing applications. These machines utilize microwave technology to rapidly and efficiently remove moisture from food products, including eggs, resulting in higher quality dried products with shorter processing times.

One of the primary advantages of Industrial Microwave Drying Machines is their speed and efficiency. Compared to conventional drying methods such as air drying or oven drying, microwave drying significantly reduces drying times, allowing for faster throughput and increased production capacity. This efficiency not only improves productivity but also reduces energy consumption and operating costs.

Additionally, Industrial Microwave Drying Machines offer superior control over the drying process, allowing for precise adjustment of temperature, humidity, and airflow. This level of control ensures consistent drying results and helps to preserve the nutritional integrity and sensory qualities of food products, including eggs.

Moreover, Industrial Microwave Drying Machines are highly versatile and can accommodate a wide range of food products, sizes, and shapes. Whether drying eggs, fruits, vegetables, or grains, these machines can be customized to meet the specific requirements of different food processing applications, providing flexibility and adaptability in production.

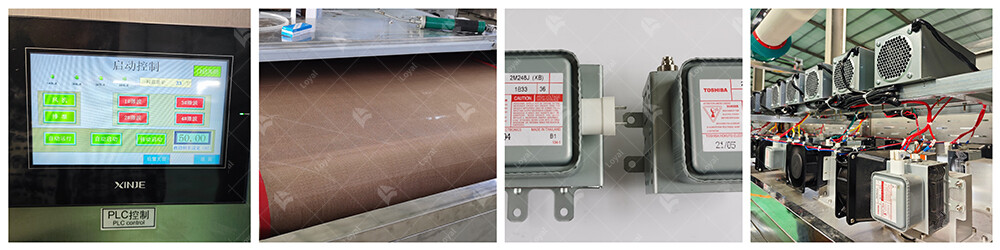

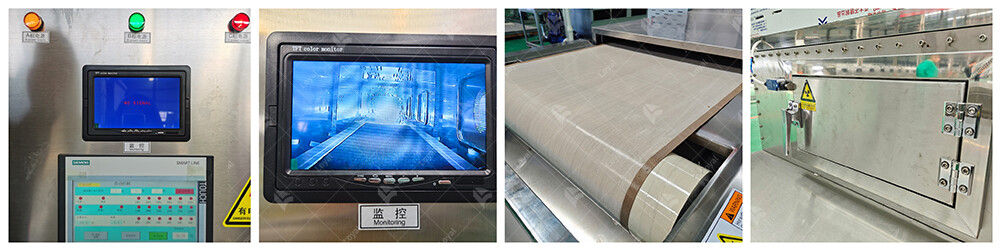

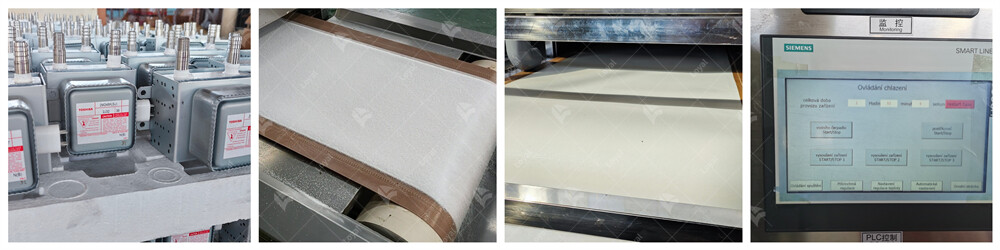

Design and Components of Industrial Microwave Food Egg Drying Machine

Industrial microwave food egg drying machines are meticulously crafted to cater to the specific needs of the food industry, especially in the preservation and processing of eggs. These machines typically consist of several key components designed to facilitate efficient drying while maintaining food safety standards.

One integral component of an industrial microwave food egg drying machine is the microwave chamber. This chamber is where the eggs are placed for drying and is constructed with materials that allow for the efficient transmission of microwave energy. It is designed to ensure uniform heating and drying of the eggs, resulting in consistent quality throughout the batch.

Another crucial element is the microwave generator, which produces the electromagnetic waves necessary for drying the eggs. These generators are equipped with advanced technology to control the frequency and power of the microwaves, allowing for precise adjustment according to the specific requirements of the eggs being processed.

Additionally, industrial microwave food egg drying machines feature a conveyor system that moves the eggs through the drying chamber in a continuous or batch process. The conveyor belt is designed to withstand the heat generated during drying and is constructed with materials that are food-safe and easy to clean.

In summary, the design and components of industrial microwave food egg drying machines are carefully engineered to deliver efficient and effective drying solutions for the food industry. From the microwave chamber to the conveyor system and temperature sensors, each component plays a crucial role in ensuring consistent and high-quality dried eggs.

Operating Principles of Microwave Drying for Food Eggs

Microwave drying is a highly efficient method for removing moisture from food products, including eggs, in industrial settings. The operating principles of microwave drying for food eggs involve the application of electromagnetic waves to heat and evaporate the moisture content within the eggs.

The process begins with the placement of the eggs inside the microwave chamber of the drying machine. Once the chamber is sealed, the microwave generator emits electromagnetic waves at a specific frequency, typically in the range of 300 MHz to 300 GHz. These waves penetrate the eggs and cause the water molecules within them to oscillate rapidly, generating heat through friction.

As the eggs heat up, the moisture within them begins to evaporate, resulting in drying. The conveyor system moves the eggs through the drying chamber, ensuring uniform exposure to the microwaves for consistent drying across all the eggs. Temperature and moisture sensors continuously monitor the drying process, allowing for precise control and adjustment as needed.

One key advantage of microwave drying for food eggs is its speed and efficiency. Unlike traditional drying methods, which rely on convection or conduction heat transfer, microwave drying heats the eggs from the inside out, significantly reducing drying times. This results in higher throughput and increased productivity for food manufacturers.

Moreover, microwave drying preserves the quality and nutritional value of the eggs better than conventional drying methods. By minimizing exposure to high temperatures and shortening drying times, microwave drying helps retain the natural color, flavor, and texture of the eggs while ensuring food safety standards are met.

In conclusion, the operating principles of microwave drying for food eggs involve the controlled application of electromagnetic waves to heat and remove moisture from the eggs. This efficient and effective drying method offers advantages in terms of speed, quality preservation, and food safety, making it an ideal choice for industrial egg processing applications.

Efficiency and Energy Savings in Industrial Microwave Drying

Industrial microwave food egg drying machines are renowned for their efficiency and energy-saving capabilities. These machines utilize microwave technology to rapidly and evenly dry food products, including eggs, while minimizing energy consumption. One key factor contributing to their efficiency is the ability to selectively heat the moisture within the food product, leading to faster drying times compared to traditional methods.

To achieve optimal efficiency, industrial microwave food egg drying machines are designed with advanced features such as precise temperature and power control. This allows operators to customize drying parameters according to the specific requirements of the product, ensuring maximum efficiency while minimizing energy waste. Additionally, the design of these machines often includes insulated chambers to prevent heat loss, further enhancing energy savings.

Moreover, industrial microwave food egg drying machines typically have a high throughput capacity, allowing large quantities of eggs to be processed quickly and efficiently. This high throughput, coupled with the rapid drying capabilities of microwave technology, results in overall energy savings by reducing the time and resources required for the drying process.

In summary, industrial microwave food egg drying machines offer significant efficiency and energy savings compared to traditional drying methods. Their ability to rapidly dry food products while minimizing energy consumption makes them a preferred choice for food processing industries seeking to optimize their operations and reduce costs.

Safety Measures for Operating Industrial Microwave Drying Equipment

Safety is paramount when operating industrial microwave food egg drying machines to ensure the well-being of operators and the integrity of the product. These machines utilize high-power microwave radiation to heat and dry food products, which can pose potential hazards if not handled properly. Therefore, stringent safety measures must be implemented and adhered to during operation.

First and foremost, operators must undergo comprehensive training on the safe use and handling of industrial microwave drying equipment. This includes understanding the potential risks associated with microwave radiation exposure and how to mitigate them effectively. Protective gear, such as gloves and safety goggles, should be worn at all times to prevent direct contact with hot surfaces and minimize the risk of injury.

In addition to equipment-specific safety measures, proper hygiene and sanitation practices must be observed to prevent contamination of food products during the drying process. This includes regular cleaning of the machine components and adherence to food safety regulations and guidelines.

Overall, implementing comprehensive safety measures is crucial for the safe operation of industrial microwave food egg drying machines, protecting both personnel and product quality. By following strict safety protocols and guidelines, operators can minimize risks and ensure a safe working environment in food processing facilities.

Applications and Industries Benefiting from Food Egg Drying Machines

Industrial microwave food egg drying machines have found widespread applications across various industries, revolutionizing the way eggs are processed and preserved. One of the primary sectors benefiting from these machines is the food processing industry. These machines enable food manufacturers to efficiently dry eggs for use in various food products such as baked goods, pasta, and sauces. By removing moisture from eggs through microwave drying, manufacturers can prolong the shelf life of their products while maintaining quality and flavor.

Additionally, the pharmaceutical industry has also embraced the use of industrial microwave food egg drying machines. Eggs are often used as a raw material in the production of certain medications and vaccines. Microwave drying technology ensures that the eggs are thoroughly dried while preserving their biological properties, making them suitable for pharmaceutical applications. This has led to increased efficiency and reliability in pharmaceutical manufacturing processes.

Moreover, the pet food industry has recognized the benefits of using food egg drying machines. Eggs are a valuable source of protein and nutrients in pet food formulations. Industrial microwave drying machines allow pet food manufacturers to efficiently incorporate dried eggs into their products, enhancing their nutritional content. This has resulted in the production of higher quality pet foods that meet the dietary needs of companion animals.

Furthermore, the agriculture sector has seen significant advancements with the adoption of food egg drying machines. Farmers and egg producers can now efficiently dry surplus eggs for storage and distribution. This helps prevent waste and ensures that eggs remain available year-round, even during periods of oversupply. Additionally, by drying eggs, farmers can create value-added products for sale to consumers, further increasing their profitability.

In conclusion, industrial microwave food egg drying machines have diverse applications across industries such as food processing, pharmaceuticals, pet food manufacturing, and agriculture. Their ability to efficiently dry eggs while preserving their quality and nutritional value has led to increased efficiency, product quality, and profitability for businesses in these sectors.

Future Trends and Innovations in Industrial Microwave Drying Technology

The future of industrial microwave drying technology holds promising advancements and innovations that will further enhance efficiency, productivity, and sustainability. One notable trend is the development of smart drying systems equipped with advanced sensors and artificial intelligence algorithms. These systems can monitor and adjust drying parameters in real-time, optimizing energy consumption and product quality.

Additionally, there is a growing focus on the integration of renewable energy sources such as solar and wind power into industrial microwave drying systems. This move towards sustainable energy solutions not only reduces environmental impact but also lowers operating costs for businesses.

Another area of innovation is the development of novel materials and coatings for microwave drying equipment. These materials can enhance heat transfer and reduce energy loss during the drying process, leading to faster drying times and higher throughput. Additionally, research is underway to explore the potential of microwave-assisted drying techniques for non-thermal processing applications such as sterilization and pasteurization.

Furthermore, the integration of Industry 4.0 technologies such as internet-of-things (IoT) connectivity and cloud-based data analytics is poised to revolutionize industrial microwave drying operations. These technologies enable remote monitoring and control of drying processes, predictive maintenance, and data-driven optimization, resulting in improved efficiency and reliability.

In conclusion, the future of industrial microwave drying technology is characterized by advancements in smart systems, renewable energy integration, material science, and digitalization. These innovations will drive efficiency, sustainability, and competitiveness in industrial drying operations across various sectors.

References

The following are five authoritative foreign literature websites in the field of industrial microwaves:

1. IEEE Xplore Digital Library

Website: [https://ieeexplore.ieee.org/]

2.ScienceDirect

Website: [https://www.sciencedirect.com/]

3. SpringerLink

Website: [https://link.springer.com/]

4. Wiley Online Library

Website: [https://onlinelibrary.wiley.com/]

5. PubMed

Website: [https://pubmed.ncbi.nlm.nih.gov/]

Telephone :+86-531-55583139

Telephone :+86-531-55583139 WhatsApp :+86 13256674591

WhatsApp :+86 13256674591 Email :

Email :