Everything you Need to Know About Industrial Hazelnut Microwave Drying Machine

Introduction to Industrial Hazelnut Microwave Drying Machine

Industrial Hazelnut Microwave Drying Machines are cutting-edge equipment designed to efficiently remove moisture from hazelnuts using microwave technology. These machines are revolutionizing the hazelnut processing industry by offering faster drying times, higher quality end products, and increased energy efficiency.

These drying machines utilize microwave radiation to heat the hazelnuts evenly and rapidly, allowing for precise control over the drying process. Unlike traditional drying methods such as air drying or oven drying, which can be slow and inconsistent, Industrial Hazelnut Microwave Drying Machines offer a more reliable and uniform drying experience.

How Does Industrial Hazelnut Microwave Drying Machine Work?

Industrial Hazelnut Microwave Drying Machine operates by emitting microwave radiation, which penetrates the hazelnuts and heats the water molecules inside. As the water molecules absorb the microwave energy, they become agitated and generate heat, leading to the evaporation of moisture from the hazelnuts. This process occurs rapidly and uniformly throughout the hazelnuts, ensuring consistent drying results. Unlike conventional drying methods that rely on convection or conduction heating, microwave drying offers unparalleled speed and efficiency, making it ideal for large-scale industrial applications.

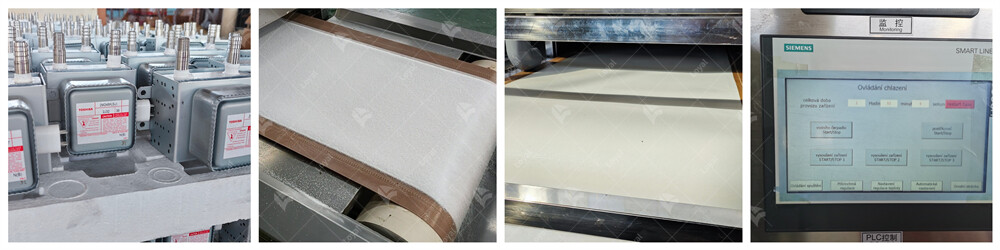

The Industrial Hazelnut Microwave Drying Machine consists of a chamber where the hazelnuts are placed on a conveyor belt or tray. Inside the chamber, microwave generators emit electromagnetic waves at specific frequencies tailored to the moisture content and properties of hazelnuts. The waves penetrate the hazelnuts and cause the water molecules to oscillate, resulting in friction and heat generation. As a result, the moisture inside the hazelnuts evaporates, leaving them dry and ready for further processing or packaging.

Industrial Hazelnut Microwave Drying Machine offers several advantages over traditional drying methods. Firstly, it significantly reduces drying time, allowing for higher throughput and increased productivity. Secondly, microwave drying preserves the natural color, flavor, and nutritional quality of hazelnuts by minimizing heat exposure and oxidation. Additionally, it requires less energy compared to conventional drying methods, leading to cost savings and environmental benefits. Overall, Industrial Hazelnut Microwave Drying Machine revolutionizes the hazelnut processing industry by offering a faster, more efficient, and higher-quality drying solution.

Benefits of Using Industrial Hazelnut Microwave Drying Machine

Industrial Hazelnut Microwave Drying Machines offer a plethora of advantages that make them a preferred choice in the food processing industry. Let's explore some of the key benefits:

Firstly, Industrial Hazelnut Microwave Drying Machines provide efficient drying. Unlike traditional drying methods that rely on convection or conduction, microwave drying utilizes electromagnetic waves to penetrate the hazelnuts, heating them from the inside out. This results in faster drying times, allowing for increased productivity and throughput.

Secondly, these machines offer uniform drying. The controlled application of microwave energy ensures that each hazelnut receives consistent heat distribution, eliminating the risk of uneven drying or hot spots. This uniformity not only improves the quality of the final product but also reduces the likelihood of spoilage.

Additionally, Industrial Hazelnut Microwave Drying Machines promote energy efficiency. By directly targeting the moisture within the hazelnuts, microwave drying minimizes heat loss and energy wastage compared to traditional drying methods. This translates to lower operating costs and a more environmentally sustainable production process.

Furthermore, these machines enable preservation of nutritional value. Unlike prolonged exposure to high temperatures in conventional drying methods, microwave drying preserves the natural nutrients and flavor of hazelnuts by minimizing thermal degradation. This results in a final product that retains its nutritional integrity and sensory characteristics, meeting consumer demand for healthier food options.

Key Features of Industrial Hazelnut Microwave Drying Machine

Industrial Hazelnut Microwave Drying Machines boast several key features that make them indispensable tools in the food processing industry. Let's explore some of these standout features:

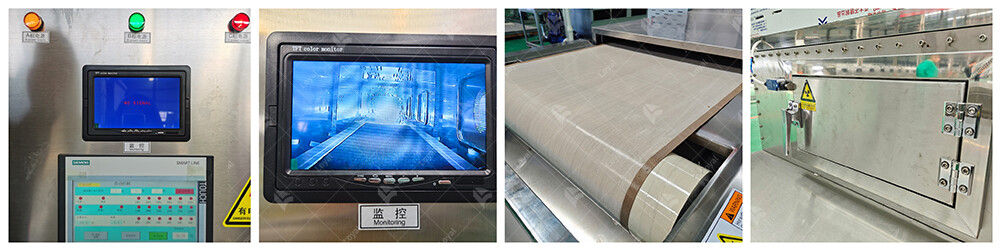

First and foremost, these machines are equipped with advanced microwave technology. Utilizing high-powered microwave generators, Industrial Hazelnut Microwave Drying Machines generate electromagnetic waves at precise frequencies and intensities, allowing for optimal drying conditions tailored to hazelnuts.

Moreover, these machines feature precision control systems. With programmable settings for temperature, humidity, and drying time, operators have the flexibility to customize the drying process according to specific requirements. This precision control ensures consistent results and minimizes the risk of over-drying or under-drying.

Additionally, Industrial Hazelnut Microwave Drying Machines are designed for ease of operation and maintenance. User-friendly interfaces and intuitive controls simplify operation, while modular construction facilitates easy access for cleaning and servicing. This reduces downtime and maximizes operational efficiency.

Furthermore, these machines prioritize food safety and hygiene. Constructed from food-grade materials and equipped with sanitary design features, Industrial Hazelnut Microwave Drying Machines adhere to strict hygiene standards and regulations. This ensures the integrity and safety of the final product, meeting consumer expectations for quality and purity.

Comparison: Industrial Hazelnut Microwave Drying Machine vs. Traditional Drying Methods

Industrial Hazelnut Microwave Drying Machine and traditional drying methods serve the purpose of removing moisture from hazelnuts, but they employ vastly different techniques.

Industrial Hazelnut Microwave Drying Machine utilizes microwave radiation to heat the hazelnuts from the inside out. This method is highly efficient, as it heats the water molecules within the nuts directly, resulting in faster drying times compared to traditional methods.

In contrast, traditional drying methods often involve air drying or sun drying the hazelnuts. While these methods are more accessible and require less specialized equipment, they are significantly slower and may result in longer processing times.

Another point of comparison is the quality of the final product. Industrial Hazelnut Microwave Drying Machine typically preserves more of the natural flavor and nutrients of the hazelnuts compared to traditional methods. This is because microwave drying allows for precise control over temperature and moisture levels, minimizing the risk of overcooking or degradation of the nuts.

Additionally, Industrial Hazelnut Microwave Drying Machine offers greater consistency and uniformity in drying compared to traditional methods. With precise control over parameters such as temperature and humidity, manufacturers can ensure that each batch of hazelnuts is dried to the same high standard, resulting in a more reliable end product.

Applications of Industrial Hazelnut Microwave Drying Machine

Industrial Hazelnut Microwave Drying Machine finds wide-ranging applications across various industries due to its efficiency and effectiveness in drying hazelnuts.

One primary application of Industrial Hazelnut Microwave Drying Machine is in the food industry. Hazelnuts are a popular ingredient in various food products, including chocolates, baked goods, and confectionery. By using Industrial Hazelnut Microwave Drying Machine, manufacturers can efficiently dry hazelnuts to the desired moisture content, ensuring the quality and shelf life of the final products.

Another significant application is in the nut processing industry. Industrial Hazelnut Microwave Drying Machine enables nut processors to efficiently dry large quantities of hazelnuts for packaging and distribution. This helps meet the demand for dried hazelnuts in both domestic and international markets.

Industrial Hazelnut Microwave Drying Machine is also utilized in the pharmaceutical and nutraceutical industries. Dried hazelnuts are often used as ingredients in dietary supplements and herbal remedies. By employing Industrial Hazelnut Microwave Drying Machine, manufacturers can ensure that the hazelnuts retain their nutritional value and potency during the drying process.

Factors to Consider When Choosing an Industrial Hazelnut Microwave Drying Machine

When selecting an Industrial Hazelnut Microwave Drying Machine, several crucial factors demand attention to ensure optimal performance and efficiency. Let's explore these considerations in detail:

1. Capacity and Throughput:When choosing an Industrial Hazelnut Microwave Drying Machine, it's essential to consider your production requirements. Evaluate the machine's capacity and throughput capabilities to ensure it can handle the volume of hazelnuts you intend to process. Select a machine that aligns with your production goals to avoid bottlenecks and maximize efficiency.

2. Microwave Technology and Power:The efficiency of microwave drying heavily depends on the technology and power of the equipment. Assess the microwave technology used in the machine and its power output to determine its effectiveness in drying hazelnuts uniformly and efficiently. Higher power machines can often dry hazelnuts faster, but ensure it's balanced with the quality of the final product and energy consumption.

3. Control and Automation:Opt for an Industrial Hazelnut Microwave Drying Machine equipped with advanced control and automation features. These include precise temperature and humidity controls, automated processes, and real-time monitoring capabilities. Such features enhance operational control, ensure consistent drying results, and minimize the risk of errors during operation.

4. Quality and Safety Standards:Prioritize machines that comply with industry quality and safety standards. Look for certifications and endorsements indicating adherence to hygiene, safety, and food quality regulations. Choosing a reputable manufacturer known for producing reliable and compliant equipment can provide peace of mind regarding the quality and safety of your hazelnut drying process.

Maintenance Tips for Industrial Hazelnut Microwave Drying Machine

Maintaining an Industrial Hazelnut Microwave Drying Machine is vital to ensure its longevity, efficiency, and optimal performance. Here are essential maintenance tips to keep your equipment in top condition:

1. Regular Cleaning and Inspection:Schedule routine cleaning and inspection sessions to remove any debris, residue, or contaminants that may accumulate within the machine. Pay particular attention to microwave components, conveyor systems, and ventilation systems to prevent buildup that could affect drying efficiency or pose hygiene risks.

2. Lubrication and Component Checks:Regularly lubricate moving parts such as bearings, chains, and gears to reduce friction and prevent premature wear. Conduct thorough checks of all machine components, including seals, belts, and electrical connections, to identify any signs of damage or deterioration that require immediate attention.

3. Calibration and Adjustment:Periodically calibrate the machine's temperature and humidity controls to ensure accurate drying conditions. Verify the alignment of conveyor belts and other moving parts to maintain smooth operation and prevent misalignment-related issues that could impact performance.

4. Training and Operator Awareness:Provide comprehensive training to operators responsible for operating and maintaining the Industrial Hazelnut Microwave Drying Machine. Ensure they understand proper operating procedures, safety protocols, and maintenance requirements to minimize the risk of accidents, errors, or equipment damage. Encourage a culture of vigilance and proactive maintenance among the workforce to preserve the machine's longevity and efficiency.

Safety Precautions When Operating Industrial Hazelnut Microwave Drying Machine

Operating an Industrial Hazelnut Microwave Drying Machine requires adherence to strict safety protocols to ensure the well-being of operators and maintain optimal performance of the equipment.

First and foremost, operators should undergo comprehensive training on the proper usage of the Industrial Hazelnut Microwave Drying Machine. This includes familiarizing themselves with the control panel, emergency shut-off procedures, and safety features integrated into the machine. Additionally, operators must wear appropriate personal protective equipment (PPE) such as gloves, safety glasses, and protective clothing to minimize the risk of injury during operation.

Regular maintenance and inspection of the Industrial Hazelnut Microwave Drying Machine are crucial for identifying and addressing potential safety hazards. This includes checking for loose components, damaged wiring, and signs of wear and tear that could compromise the integrity of the machine. Any issues should be promptly reported and repaired by qualified technicians to prevent accidents or malfunctions.

When loading hazelnuts into the Industrial Hazelnut Microwave Drying Machine, operators must ensure that the product is evenly distributed and does not exceed the machine's capacity. Overloading the machine can lead to uneven drying and overheating, increasing the risk of fire or damage to the equipment. Additionally, operators should be cautious when handling hot surfaces and steam generated during the drying process to avoid burns or scalds.

Finally, operators should be vigilant and attentive while the Industrial Hazelnut Microwave Drying Machine is in operation. They should monitor the drying process closely, looking out for any abnormal sounds, smells, or visual cues that could indicate a problem. In the event of an emergency or malfunction, operators should know how to quickly shut down the machine and follow established procedures for addressing the issue safely.

Future Trends in Industrial Hazelnut Microwave Drying Machine Technology

The future of Industrial Hazelnut Microwave Drying Machine technology holds promising advancements aimed at enhancing efficiency, productivity, and sustainability in the food processing industry.

One notable trend is the integration of smart technology and automation into Industrial Hazelnut Microwave Drying Machines. This includes the development of intelligent control systems that optimize drying parameters based on real-time data such as humidity levels, temperature, and product characteristics. By leveraging machine learning algorithms, these advanced systems can adapt to changing conditions and improve drying performance while reducing energy consumption and waste.

Another emerging trend is the use of renewable energy sources to power Industrial Hazelnut Microwave Drying Machines. With a growing emphasis on environmental sustainability, manufacturers are exploring alternative energy sources such as solar, wind, and biomass to reduce reliance on fossil fuels and minimize carbon emissions. Additionally, advancements in energy-efficient microwave technology are enabling more eco-friendly drying processes that consume less electricity and produce lower greenhouse gas emissions.

In conclusion, the future of Industrial Hazelnut Microwave Drying Machine technology is characterized by innovation, sustainability, and accessibility. By embracing smart technology, renewable energy, and modular design principles, manufacturers are poised to revolutionize the food processing industry and meet the evolving needs of consumers and businesses alike.

References

1.Tetra Pak : https://www.tetrapak.com

2.Jinan Kelid Machinery Co., Ltd.: http://www.kldfoodmachine.com

3. GEA : https://www.gea.com

4. MAX Industrial Microwave: https://www.maxindustrialmicrowave.com

5. Marel: https://marel.com

Telephone :+86-531-55583139

Telephone :+86-531-55583139 WhatsApp :+86 13256674591

WhatsApp :+86 13256674591 Email :

Email :