Everything you Need to Know About Coriander Seed Powder Spice Dryer Machine

Introduction to Coriander Seed Powder Spice Dryer Machine

Coriander seed powder spice dryer machines are essential equipment in the food processing industry, particularly for manufacturers dealing with spices and seasonings. These machines play a crucial role in drying coriander seed powder spice efficiently and effectively, ensuring quality and preserving the flavor of the spice.

Coriander seed powder is a common ingredient in various cuisines worldwide, prized for its distinct flavor and aroma. However, to maintain its quality and extend its shelf life, proper drying is essential. This is where coriander seed powder spice dryer machines come into play.

These machines are designed to remove moisture from the coriander seed powder spice quickly and evenly, using a combination of heat and airflow. By controlling temperature and airflow parameters, manufacturers can achieve optimal drying conditions, ensuring the spice retains its flavor, color, and nutritional value.

Coriander seed powder spice dryer machines come in various sizes and configurations, catering to different production scales and requirements. From small-scale operations to large industrial facilities, there's a dryer machine available to suit every need.

In addition to drying coriander seed powder spice, these machines can also be used for drying other spices and seasonings, making them versatile and cost-effective solutions for food processing businesses.

How Does the Coriander Seed Powder Spice Dryer Work?

Coriander seed powder spice dryer machines operate on the principle of convective heat transfer. The process begins by loading the coriander seed powder spice onto trays or conveyor belts inside the dryer chamber.

Once loaded, the machine activates heating elements, raising the temperature inside the chamber to the desired level. Simultaneously, a powerful fan circulates hot air throughout the chamber, ensuring even distribution of heat and moisture removal.

As the hot air passes over the coriander seed powder spice, it absorbs moisture from the surface of the particles, causing evaporation. The moisture-laden air is then expelled from the chamber, while fresh, dry air is continuously introduced to maintain optimal drying conditions.

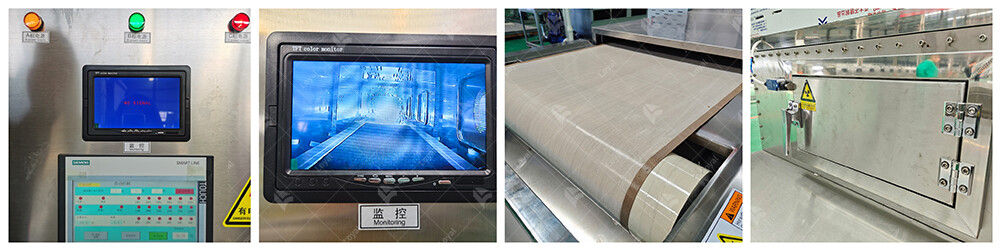

Throughout the drying process, operators can monitor and adjust temperature and airflow settings to achieve the desired level of dryness. Advanced control systems and sensors help automate this process, ensuring consistent results batch after batch.

Once the coriander seed powder spice reaches the desired moisture content, the drying cycle is complete. The dried spice is then discharged from the machine for further processing or packaging, ready for distribution to consumers worldwide.

Overall, coriander seed powder spice dryer machines offer a reliable and efficient solution for food manufacturers looking to dry spices and seasonings effectively while preserving their quality and flavor.

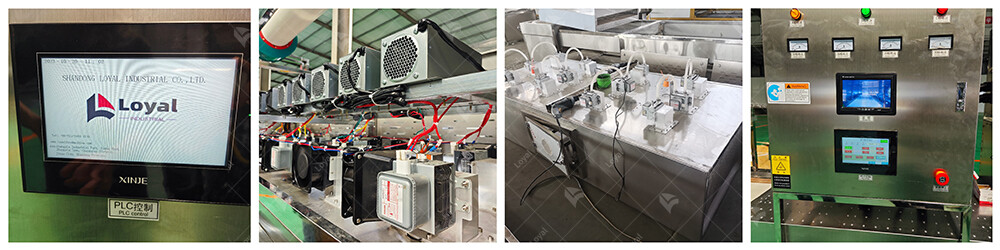

Understanding the Components of the Dryer Machine

The Coriander Seed Powder Spice Dryer Machine is a sophisticated piece of equipment designed specifically for the drying process in the spice industry. Understanding its components is crucial for efficient operation.

1. Heating System: The heart of the dryer machine, the heating system, typically consists of electric heaters or gas burners. These elements generate the necessary heat to evaporate moisture from the coriander seed powder spice. Advanced models may utilize infrared heating technology for faster and more uniform drying.

2. Air Circulation System: A robust air circulation system is essential to ensure even drying throughout the drying chamber. This system comprises fans or blowers that circulate hot air uniformly, preventing moisture buildup and ensuring consistent drying results. Additionally, air filters are incorporated to maintain air quality and prevent contamination of the spice powder.

3. Drying Chamber: The drying chamber is where the magic happens. It's a controlled environment where the coriander seed powder spice is subjected to the optimal combination of heat and airflow to remove moisture efficiently. The chamber is typically insulated to minimize heat loss and maximize energy efficiency.

4. Control Panel: Modern Coriander Seed Powder Spice Dryer Machines are equipped with advanced control panels for precise regulation of drying parameters. Operators can adjust temperature, airflow, and drying time according to specific requirements, ensuring optimal drying results and product quality.

Benefits of Using a Coriander Seed Powder Spice Dryer

Investing in a Coriander Seed Powder Spice Dryer Machine offers numerous advantages, making it a smart choice for spice manufacturers looking to optimize their production processes.

1. Improved Efficiency: Compared to traditional drying methods such as sun drying or air drying, a dryer machine offers significantly higher efficiency. It reduces drying time and increases throughput, allowing manufacturers to meet demand more effectively and enhance productivity.

2. Enhanced Quality: The controlled drying environment of a dryer machine ensures consistent quality in the coriander seed powder spice. By eliminating moisture quickly and uniformly, it preserves the flavor, aroma, and nutritional content of the spice, resulting in a superior end product that meets or exceeds industry standards.

3. Cost Savings: While the initial investment in a Coriander Seed Powder Spice Dryer Machine may seem significant, it offers long-term cost savings. Reduced drying time translates to lower energy consumption, and the enhanced quality minimizes the risk of product spoilage or rejections, ultimately leading to higher profitability for manufacturers.

4. Flexibility and Customization: Dryer machines are highly versatile and can be tailored to meet specific drying requirements. Whether it's adjusting temperature and airflow for different types of spices or incorporating additional features for process optimization, manufacturers have the flexibility to customize the drying process according to their needs.

Maintenance Tips for Prolonging Machine Lifespan

Maintaining your Coriander Seed Powder Spice Dryer Machine is crucial for ensuring its longevity and optimal performance. Here are some expert tips to help you keep your machine in top condition.

1. Regular Cleaning and Inspection: Regularly clean the dryer machine inside and out to prevent the buildup of dust, debris, and spice residues. Inspect the machine for any signs of wear and tear, such as loose bolts or damaged components.

2. Lubrication: Proper lubrication of moving parts is essential for smooth operation and to prevent friction-related damage. Follow the manufacturer's recommendations for the type and frequency of lubrication required for your specific machine.

3. Temperature and Humidity Control: Maintain optimal temperature and humidity levels in the drying environment to prevent corrosion and rust formation on the machine's metal components. Use dehumidifiers or air conditioning systems if necessary to control humidity levels.

4. Scheduled Maintenance Checks: Implement a regular maintenance schedule, including routine inspections, parts replacement, and calibration checks. Keep detailed records of maintenance activities and repairs performed to track the machine's performance over time.

Differentiating Between Types of Dryer Machines

When it comes to Coriander Seed Powder Spice Dryer Machines, there are several types available on the market. Each type offers unique features and benefits to suit different production needs. Here's a brief overview of the most common types:

1. Convection Dryers: Convection dryers use hot air to remove moisture from spices, herbs, and other food products. They offer fast drying times and uniform heat distribution, making them ideal for large-scale production.

2. Vacuum Dryers: Vacuum dryers operate under reduced pressure, allowing moisture to evaporate at lower temperatures. They are suitable for drying heat-sensitive materials and preserving the flavor and aroma of delicate spices like coriander seeds.

3. Spray Dryers: Spray dryers use atomization to convert liquid spice extracts into fine droplets, which are then dried by hot air. They are commonly used for producing powdered spices with high solubility and instant dissolvability.

4. Freeze Dryers: Freeze dryers freeze spices at low temperatures and then remove moisture through sublimation, preserving their color, flavor, and nutritional value. While they are slower and more expensive than other types of dryers, they are ideal for producing premium-quality spice powders.

Understanding the differences between these dryer machines will help you choose the best option for your specific application and production requirements.

Safety Precautions When Operating the Dryer Machine

When operating a Coriander Seed Powder Spice Dryer Machine, safety should always be the top priority to prevent accidents and ensure smooth operations.

1. Understanding Machine Controls and Functions:Before operating the dryer machine, familiarize yourself with its controls and functions. Ensure that you understand how to start, stop, and adjust settings to achieve the desired drying results. Refer to the user manual provided by the manufacturer for detailed instructions on machine operation.

2. Wearing Appropriate Protective Gear:Prior to engaging with the dryer machine, it is crucial to wear appropriate protective gear, including safety goggles, gloves, and closed-toe shoes. These items will help protect against potential hazards such as flying debris, heat, and chemical exposure during operation.

3. Maintaining a Clean and Organized Work Area:Keep the area around the dryer machine clean and organized to prevent tripping hazards and ensure easy access to emergency exits. Remove any obstacles or clutter that may obstruct the machine's operation or pose a safety risk to operators.

4. Regular Inspections and Maintenance:Perform regular inspections and maintenance on the dryer machine to identify any potential safety hazards or mechanical issues. Check for loose or damaged components, frayed wires, and signs of wear and tear. Address any issues promptly to prevent accidents and maintain the machine's optimal performance.

Troubleshooting Common Issues with the Dryer

Even with proper maintenance, Coriander Seed Powder Spice Dryer Machines may encounter common issues during operation. Here are some troubleshooting tips to address these issues effectively:

1. Uneven Drying:If the coriander seed powder spice is not drying evenly, check for uneven distribution of the product on the drying trays. Ensure that the trays are loaded evenly and that air circulation within the dryer is not obstructed. Adjust the drying temperature and airflow settings as needed to achieve uniform drying results.

2. Overheating:Overheating can occur if the drying temperature is set too high or if the dryer machine is overloaded with product. Reduce the drying temperature and workload to prevent overheating and ensure safe operation of the machine. Additionally, check for any obstructions in the airflow vents that may be restricting ventilation and causing overheating.

3. Excessive Noise or Vibration:

Excessive noise or vibration during operation may indicate loose or damaged components within the dryer machine. Inspect the machine for loose bolts, screws, or other fasteners, and tighten them as needed. Lubricate moving parts according to the manufacturer's recommendations to reduce friction and minimize noise and vibration.

4. Electrical Issues:

If the dryer machine experiences electrical issues such as power surges or fluctuations, check the power supply and connections for any loose or damaged wiring. Ensure that the machine is properly grounded and that electrical outlets are in good condition. If electrical issues persist, contact a qualified technician for further assistance.

By following these safety precautions and troubleshooting tips, operators can ensure safe and efficient operation of Coriander Seed Powder Spice Dryer Machines, minimizing downtime and maximizing productivity.

Cost Analysis: Investment vs. Returns

Investing in a Coriander Seed Powder Spice Dryer Machine entails careful consideration of both upfront costs and potential returns. The initial investment includes the purchase price of the machine, installation expenses, and any additional customization required. On the other hand, returns are determined by factors such as increased productivity, reduced labor costs, and improved product quality.

One significant aspect of the cost analysis is the efficiency of the dryer machine. High-quality machines may have a higher upfront cost but offer better performance and durability, leading to long-term savings. Additionally, energy efficiency plays a crucial role in operating expenses. Opting for an energy-efficient dryer can result in lower electricity bills and reduced environmental impact, contributing to overall cost savings.

Furthermore, maintenance costs should be factored into the investment equation. Regular maintenance ensures the smooth operation of the dryer machine and prolongs its lifespan. It is essential to budget for routine maintenance tasks such as cleaning, lubrication, and component replacement to prevent unexpected breakdowns and costly repairs.

Ultimately, the returns on investment in a Coriander Seed Powder Spice Dryer Machine can be substantial. Increased production capacity and efficiency result in higher output, which can lead to greater revenue generation. Moreover, the ability to produce consistently dried spices of superior quality enhances market competitiveness and customer satisfaction, further contributing to financial returns.

Future Trends in Coriander Seed Powder Spice Drying Technology

As technology continues to advance, the future of coriander seed powder spice drying is poised for significant innovation. One emerging trend is the integration of smart sensors and automation into dryer machines. These features enable real-time monitoring of drying conditions and automatic adjustment of parameters, optimizing efficiency and quality control.

Another promising development is the adoption of renewable energy sources in dryer technology. Solar-powered and biomass-fueled dryers offer sustainable alternatives to conventional energy sources, reducing operating costs and environmental impact. As sustainability becomes a priority for industries worldwide, these eco-friendly drying solutions are expected to gain traction.

Furthermore, advancements in materials science are driving improvements in dryer design and performance. Lightweight yet durable materials enhance portability and ease of installation, while advanced insulation materials improve energy efficiency and heat retention. Additionally, the use of antimicrobial coatings and hygiene-enhancing features ensures the production of safe and hygienic spice products.

In the realm of digitalization, the integration of data analytics and machine learning algorithms holds immense potential for optimizing drying processes. By analyzing large datasets on drying parameters and product characteristics, manufacturers can fine-tune their operations to achieve optimal results consistently. Predictive maintenance algorithms also help prevent equipment failures and minimize downtime, ensuring uninterrupted production.

References

1.Tetra Pak : https://www.tetrapak.com

2.Jinan Kelid Machinery Co., Ltd.: http://www.kldfoodmachine.com

3. GEA : https://www.gea.com

4. MAX Industrial Microwave: https://www.maxindustrialmicrowave.com

5. Marel: https://marel.com

Telephone :+86-531-55583139

Telephone :+86-531-55583139 WhatsApp :+86 13256674591

WhatsApp :+86 13256674591 Email :

Email :