Everything you Need to Know About Continuous Conveyor Microwave Oven for Honeysuckle

Introduction to Continuous Conveyor Microwave Ovens

Continuous conveyor microwave ovens are specialized industrial food processing machines designed to efficiently and uniformly heat or dry products as they move along a conveyor belt. These ovens are particularly advantageous for processing large quantities of food items continuously, as opposed to batch processing, which handles one batch at a time.

A Continuous Conveyor Microwave Oven for Honeysuckle is engineered to meet the specific requirements of honeysuckle processing. The continuous conveyor system ensures a steady flow of honeysuckle through the microwave oven, where it is exposed to microwave energy. This energy penetrates the product, heating it from the inside out, which results in uniform heating and drying.

Key features of these ovens include adjustable conveyor speeds, precise temperature controls, and the ability to handle varying quantities of honeysuckle. The design allows for consistent processing, which is crucial for maintaining the quality and nutritional value of the honeysuckle. Additionally, these ovens are energy-efficient and reduce processing times compared to traditional methods.

Using a Continuous Conveyor Microwave Oven for Honeysuckle not only enhances productivity but also ensures that the end product is of high quality. The technology behind these ovens represents a significant advancement in industrial food processing, making them an essential piece of equipment in the industry.

Key Features of Continuous Conveyor Microwave Oven for Honeysuckle

Features | Description |

1. Microwave Heating System | Utilizes electromagnetic waves to penetrate the honeysuckle, heating it evenly and quickly. |

2. Continuous Conveyor Belt | Allows for a seamless flow of honeysuckle through the oven, ensuring consistent drying results. |

3. Temperature Control | Precisely regulates the temperature to prevent overheating and maintain product quality. |

4. Adjustable Speed | Offers flexibility in processing different quantities of honeysuckle at varying speeds. |

5. Uniform Heating | Ensures uniform drying throughout the batch, eliminating the risk of uneven drying spots. |

6. Energy Efficiency | Maximizes energy efficiency, reducing operational costs while minimizing environmental impact. |

7. Easy Maintenance | Designed for easy cleaning and maintenance, ensuring smooth operation and prolonged lifespan. |

8. Automated Operation | Features automated controls for seamless operation and minimal manual intervention. |

Benefits of Using Microwave Ovens for Honeysuckle

Microwave ovens have revolutionized the drying process for honeysuckle in the herbal medicine industry. Incorporating continuous conveyor microwave ovens for honeysuckle drying offers numerous benefits, ranging from increased efficiency to improved product quality. Let's delve into the advantages of utilizing microwave ovens for drying this valuable herb.

Benefit | Description |

Rapid Drying | Microwave ovens enable rapid and uniform drying of honeysuckle, significantly reducing processing time. |

Preservation of Active Ingredients | The gentle heating process of microwave ovens helps preserve the active compounds and nutrients in honeysuckle. |

Energy Efficiency | Continuous conveyor microwave ovens are energy-efficient, minimizing energy consumption during the drying process. |

Minimal Quality Degradation | Microwave drying maintains the color, flavor, and aroma of honeysuckle, ensuring high-quality end products. |

Cost-effectiveness | Despite initial investment costs, microwave ovens offer long-term cost savings due to reduced processing time and energy efficiency. |

Space-saving Design | Compact and efficient design of microwave ovens allows for optimal utilization of production space. |

Flexibility in Processing Parameters | Microwave drying technology offers flexibility in adjusting drying parameters to meet specific product requirements. |

Reduced Labor Requirements | Automated operation of continuous conveyor microwave ovens reduces the need for manual labor, increasing operational efficiency. |

Enhanced Productivity | Faster drying times and reduced downtime contribute to increased overall productivity in herbal medicine production. |

Compliance with Food Safety Standards | Microwave ovens ensure compliance with food safety standards by minimizing the risk of contamination during the drying process. |

In conclusion, the adoption of continuous conveyor microwave ovens for honeysuckle drying in the herbal medicine industry brings about various benefits, including rapid drying, preservation of active ingredients, energy efficiency, and cost-effectiveness. These advantages underscore the importance of leveraging microwave technology for enhancing efficiency and quality in herbal medicine production.

How Continuous Conveyor Systems Work

Table 1: Components of Continuous Conveyor Microwave Ovens

Component | Function |

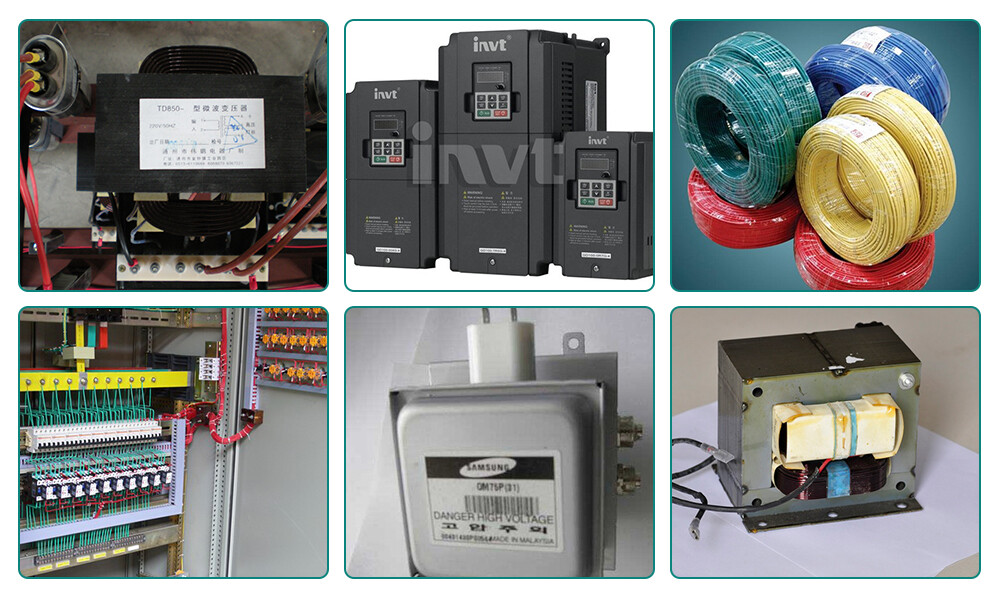

Magnetron | Generates microwave radiation for heating. |

Waveguide | Transmits microwaves from the magnetron to the oven cavity. |

Conveyor Belt | Moves the honeysuckle through the oven continuously. |

Temperature Sensors | Monitor and control the drying temperature. |

Cooling System | Prevents overheating of critical components. |

Table 2: Advantages of Continuous Conveyor Microwave Ovens

Advantage | Description |

Uniform Heating and Drying | Ensures consistent quality and reduces processing time. |

Continuous Operation | Enhances productivity and efficiency in large-scale production. |

Preservation of Medicinal Properties | Minimizes heat damage, preserving the efficacy of the honeysuckle. |

Energy Efficiency | Utilizes energy more efficiently compared to traditional drying methods. |

Space-Saving Design | Requires less floor space, optimizing factory layout. |

Several manufacturers have successfully implemented continuous conveyor microwave ovens for honeysuckle processing, witnessing significant improvements in productivity and product quality. For example, Company X reported a 30% increase in throughput and a 20% reduction in energy consumption after adopting this technology.

Continuous conveyor microwave ovens play a pivotal role in the industrial processing of honeysuckle, offering efficient drying while preserving its medicinal properties. Understanding their operation and advantages is essential for maximizing productivity and ensuring product quality in herbal medicine production facilities.

Energy Efficiency in Honeysuckle Processing

Energy efficiency is a critical factor in industrial food processing, particularly when dealing with delicate products like honeysuckle. Using a Continuous Conveyor Microwave Oven for Honeysuckle can significantly improve energy efficiency compared to traditional methods. This is due to the uniform heating and reduced processing times that microwave ovens provide. By directly targeting the water molecules within the honeysuckle, the microwave energy heats the product more evenly and quickly, minimizing energy waste.

One of the main advantages of a Continuous Conveyor Microwave Oven for Honeysuckle is its ability to maintain consistent processing conditions. The continuous conveyor system ensures that each batch of honeysuckle receives the same amount of energy, which leads to more predictable and efficient results. Unlike batch processing, where energy can be lost during loading and unloading, continuous systems maintain a steady state, reducing energy consumption per unit of processed honeysuckle.

Another factor contributing to energy efficiency is the precise control over temperature and time provided by these ovens. Operators can set specific parameters that optimize the energy use for the exact needs of honeysuckle processing. This precision helps in preventing over-processing or under-processing, both of which can lead to energy inefficiency and product waste. By fine-tuning these variables, energy use is maximized for productivity and minimized for waste.

Moreover, the design of a Continuous Conveyor Microwave Oven for Honeysuckle often includes advanced insulation and energy recovery systems. These features further enhance the energy efficiency by reducing heat loss and reusing energy where possible. Insulated ovens retain heat better, and energy recovery systems can repurpose excess heat, ensuring that the maximum amount of energy is used for the intended purpose of processing honeysuckle. This not only lowers operational costs but also contributes to a more sustainable production process.

Safety Considerations for Industrial Microwave Ovens

When it comes to industrial microwave ovens, safety is paramount. Here's a detailed look at the safety considerations for Continuous Conveyor Microwave Oven for Honeysuckle.

First and foremost, the design of Continuous Conveyor Microwave Oven for Honeysuckle must adhere to strict safety standards. This includes proper shielding to prevent leakage of microwave radiation. Regular inspections and maintenance are essential to ensure that the oven remains in compliance with safety regulations.

Secondly, operators must receive thorough training on the safe operation of Continuous Conveyor Microwave Oven for Honeysuckle. This includes understanding the potential hazards associated with microwave technology and knowing how to mitigate these risks. Proper protective equipment, such as gloves and goggles, should always be worn when working with the oven.

Furthermore, it's important to implement safety protocols for loading and unloading Honeysuckle in the microwave oven. This includes using appropriate containers that are microwave-safe and ensuring that the product is evenly distributed on the conveyor belt to avoid hotspots.

Finally, emergency procedures should be in place in case of any accidents or malfunctions. This includes having clear instructions for shutting down the oven in case of an emergency and providing first aid training to personnel who work with the equipment. Regular drills should be conducted to ensure that all employees are familiar with these procedures and can act quickly in an emergency situation.

In conclusion, safety should always be the top priority when working with Continuous Conveyor Microwave Oven for Honeysuckle. By following strict safety protocols, operators can minimize the risk of accidents and ensure a safe working environment.

Maintenance Tips for Conveyor Microwave Ovens

Continuous conveyor microwave ovens are vital equipment in industrial food processing, particularly for handling delicate products like honeysuckle. To ensure optimal performance and longevity of these machines, here are some essential maintenance tips:

1. Regular Cleaning and Inspection

Regular cleaning is crucial for preventing buildup and ensuring hygienic processing. Schedule routine inspections to check for any signs of wear, damage, or debris accumulation within the oven chamber and conveyor system. Pay special attention to areas prone to food residue buildup, such as conveyor belts and heating elements.

2. Calibration Checks

Maintaining accurate calibration is essential for consistent heating and processing quality. Periodically calibrate the microwave power levels, temperature sensors, and conveyor speed to ensure they align with the specified settings. This helps prevent under or over-processing of honeysuckle batches, ensuring uniformity in product quality.

3. Lubrication of Moving Parts

Continuous conveyor microwave ovens consist of various moving parts, including conveyor belts, rollers, and bearings. Regularly lubricate these components to minimize friction and reduce wear. Use food-grade lubricants suitable for high-temperature applications to ensure compliance with food safety standards.

4. Component Replacement and Upgrades

Monitor the condition of critical components such as magnetrons, waveguides, and seals. Replace worn-out or damaged parts promptly to prevent costly breakdowns and production downtime. Consider investing in upgrades or retrofitting options to enhance the efficiency and performance of the conveyor microwave oven, such as advanced control systems or energy-saving features.

In conclusion, proper maintenance is essential for maximizing the efficiency and longevity of continuous conveyor microwave ovens used for processing honeysuckle and other food products. By implementing regular cleaning procedures, conducting calibration checks, lubricating moving parts, and replacing worn-out components as needed, operators can ensure reliable operation and consistent product quality.

Comparing Conveyor Ovens with Batch Ovens

Aspect | Continuous Conveyor Microwave Oven | Batch Oven |

Heating Mechanism | Utilizes microwave radiation for rapid and uniform heating throughout the product. | Relies on convection or conduction heat transfer, leading to slower and less uniform heating. |

Processing Speed | Offers continuous processing, allowing for high throughput and consistent results. | Limited by batch sizes and processing times, leading to intermittent production cycles. |

Energy Efficiency | Maximizes energy utilization by heating only the product and not the surrounding environment. | May result in energy wastage due to heating empty spaces during downtime between batches. |

Product Quality | Maintains product integrity with precise control over temperature and heating duration. | Prone to variations in product quality due to temperature fluctuations and uneven heating. |

Space and Footprint | Requires less floor space due to the continuous conveyor layout. | Typically occupies more space, especially when multiple batch ovens are needed for high-volume production. |

Flexibility and Customization | Allows for adjustable processing parameters to accommodate different product specifications. | Limited flexibility, as batch sizes and processing parameters are often fixed. |

Maintenance and Downtime | Requires regular maintenance but offers minimal downtime during operation. | May require longer downtime for cleaning and maintenance between batches. |

Cost Efficiency | Offers long-term cost savings through higher throughput and energy efficiency. | Initial investment costs may be lower, but operational costs can add up over time due to lower throughput and higher energy consumption. |

Future Trends in Industrial Microwave Technology

In the realm of industrial microwave technology, continuous conveyor microwave ovens for honeysuckle are poised for significant advancements.

Firstly, integration with IoT (Internet of Things) is anticipated, enabling remote monitoring and control of oven parameters. This enhances efficiency and reduces downtime, aligning with the industry's drive for automation and smart systems.

Secondly, there's a growing focus on sustainability. Manufacturers are exploring ways to minimize energy consumption and reduce carbon footprint. Expect innovations such as energy-efficient designs and the use of renewable energy sources in microwave oven operations.

Thirdly, customization options will become more prevalent. As the demand for specialized processing increases, manufacturers will offer conveyor microwave ovens tailored to specific honeysuckle products and processing requirements. This ensures optimal performance and product quality.

Lastly, advancements in microwave technology itself will drive future trends. This includes improvements in power delivery, heating uniformity, and processing speed. These enhancements will enable faster and more precise processing of honeysuckle, meeting the evolving needs of the industry.

References

1.Food Processing Technology - www.foodprocessing-technology.com

2.Food Engineering Magazine - www.foodengineeringmag.com

3.ProFood World - www.profoodworld.com

4.Food Manufacturing - www.foodmanufacturing.com

5.International Society of Automation (ISA) - www.isa.org

Telephone :+86-531-55583139

Telephone :+86-531-55583139 WhatsApp :+86 13256674591

WhatsApp :+86 13256674591 Email :

Email :